Backlash elimination straight tooth cylindrical gear

A straight-toothed cylindrical gear and anti-backlash technology, which is applied in the direction of belts/chains/gears, components with teeth, portable lifting devices, etc., can solve the problem of backlash generation, not limited to spring elastic force, limited transmission force spring Elasticity and other problems, to achieve the effect of compensation for backlash and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

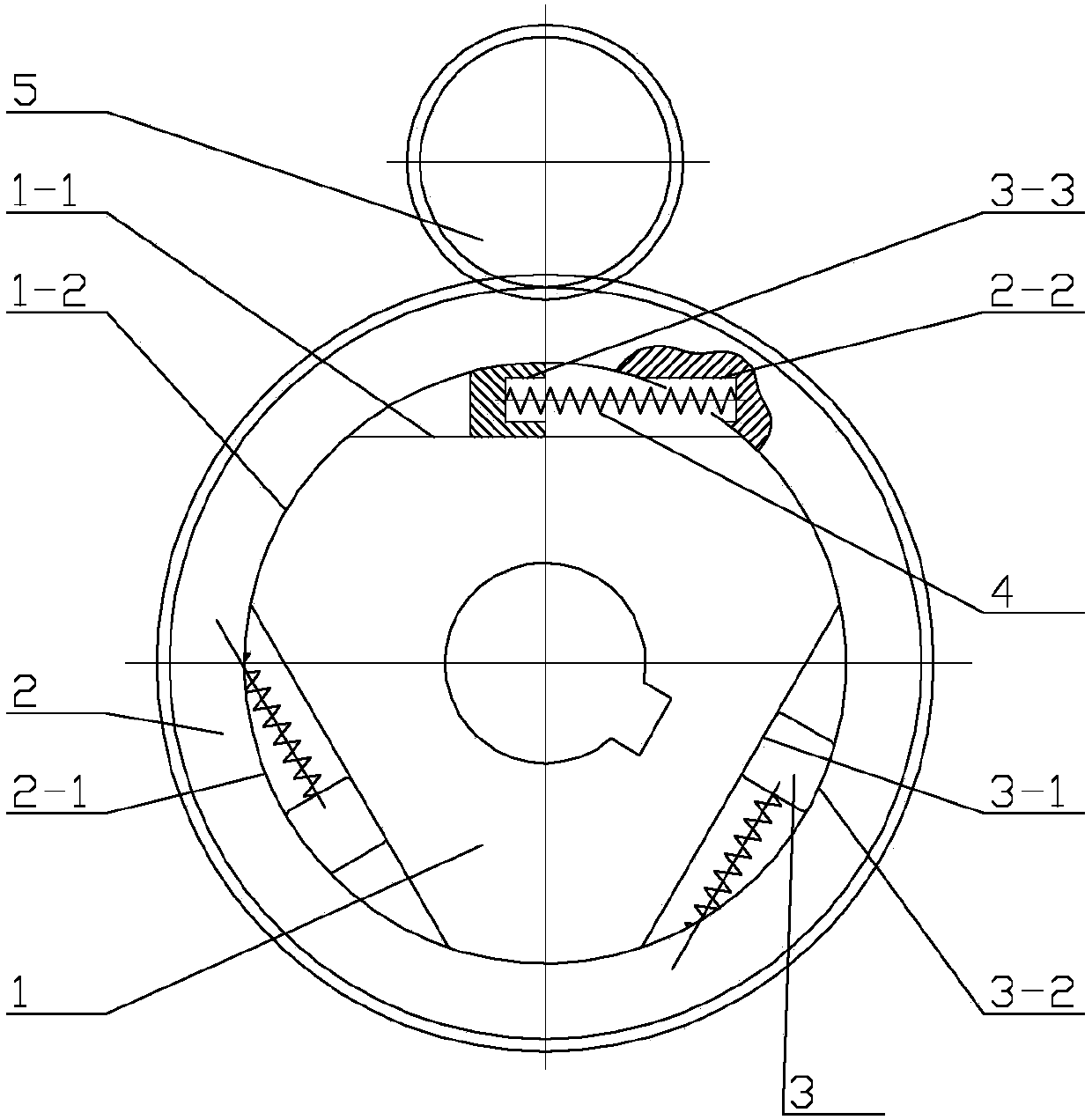

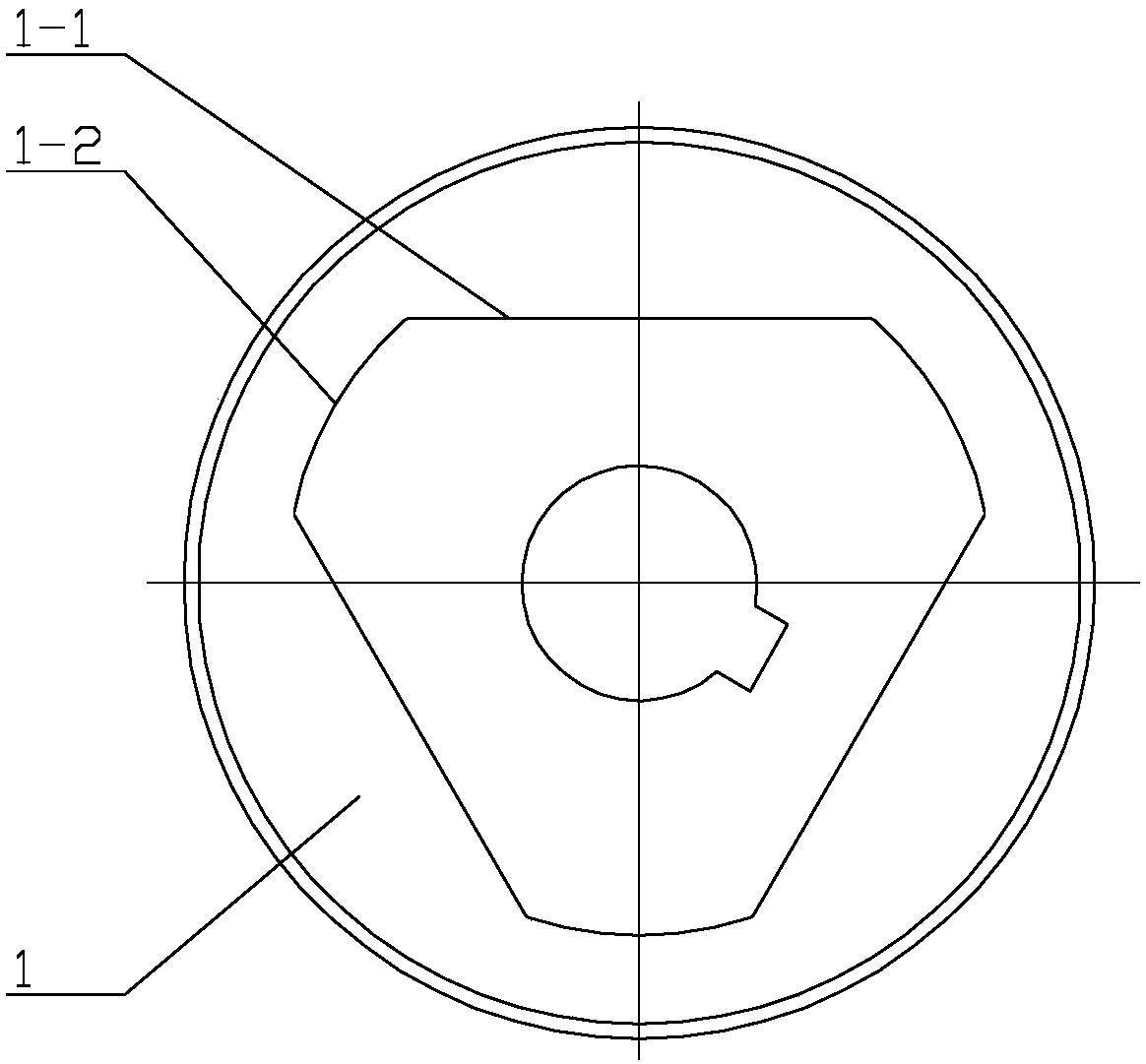

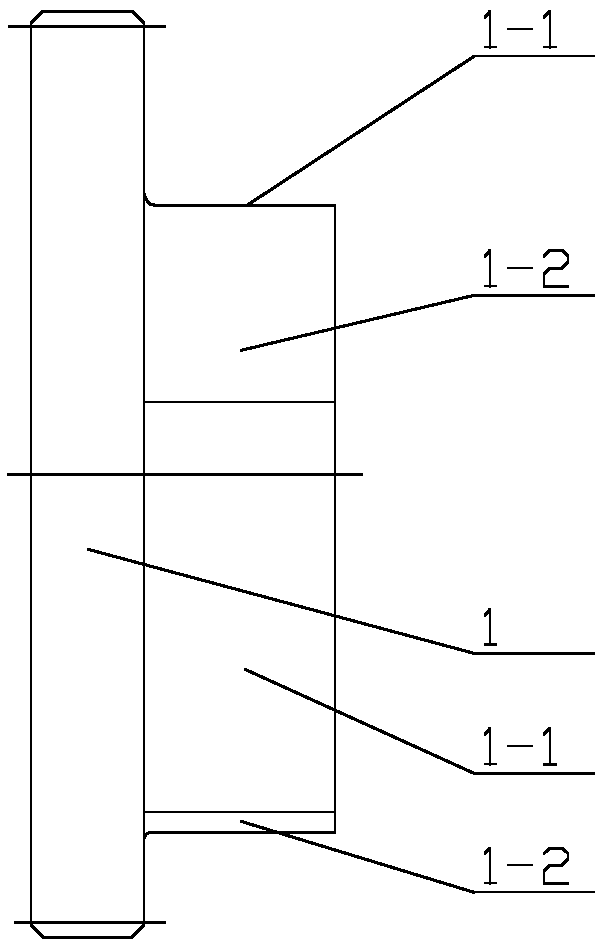

[0017] Such as figure 1 As shown, an anti-backlash spur gear includes a main gear 1, a counter gear 2, a block 3, and a spring 4; figure 1 , figure 2 , image 3 As shown, the main gear 1 is provided with a cylindrical boss coaxial with the axis of the main gear 1, and three sliding surfaces 1-1 are machined on the cylindrical boss, and the sliding surfaces 1-1 are evenly distributed on the cylindrical boss On the cylindrical surface 1-2; such as figure 1 , Figure 4 As shown, the tooth shape, parameters, and number of teeth of the secondary gear 2 are the same as those of the primary gear 1. The secondary gear 2 is provided with a large hole 2-1 coaxial with the axis of the secondary gear 2, and the cylindrical boss of the primary gear 1 is inserted into the secondary In the large hole 2-1 of the gear 2, the cylindrical surface 1-2 of the cylindrical boss rotates with the large hole 2-1 of the auxiliary gear 2, and the wall of the large hole 2-1 of the auxiliary gear 2 is provid...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap