A gearbox overdrive shifting power-assisted shifting mechanism and its use method

A shifting mechanism and overdrive technology, applied to controlled components, mechanical equipment, mechanical control devices, etc., to achieve the effects of reduced design costs, simple structure, and smooth shifting operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

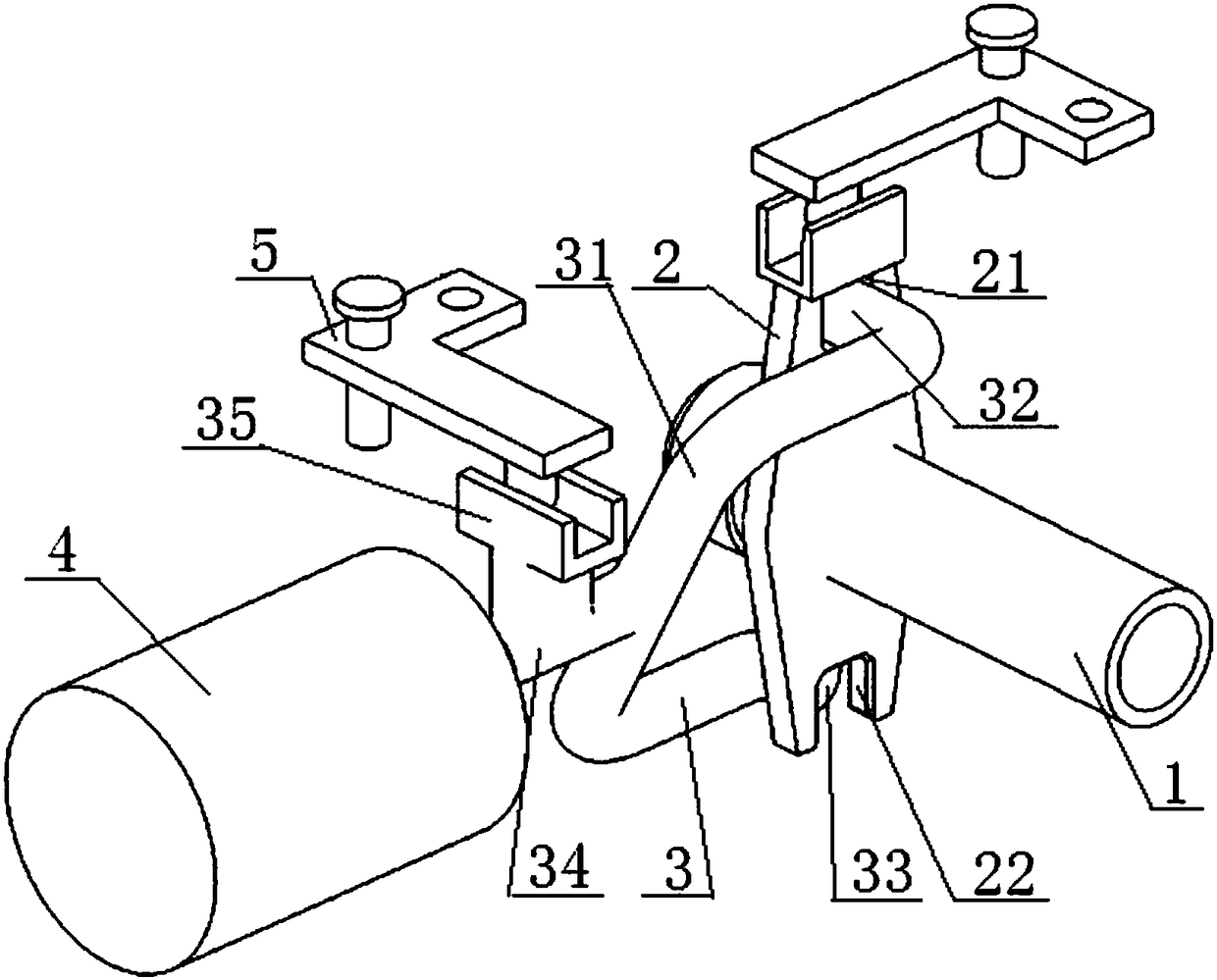

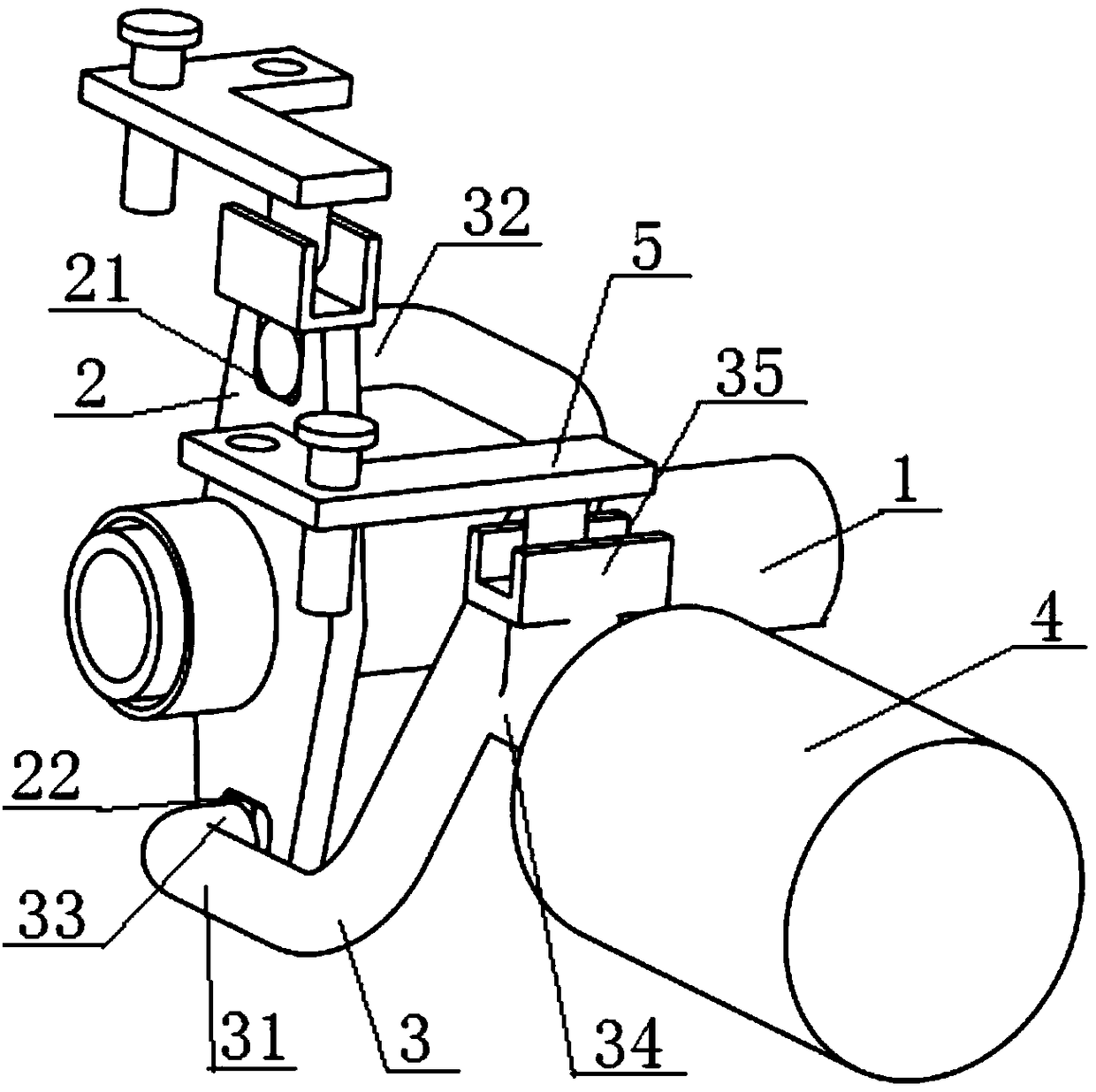

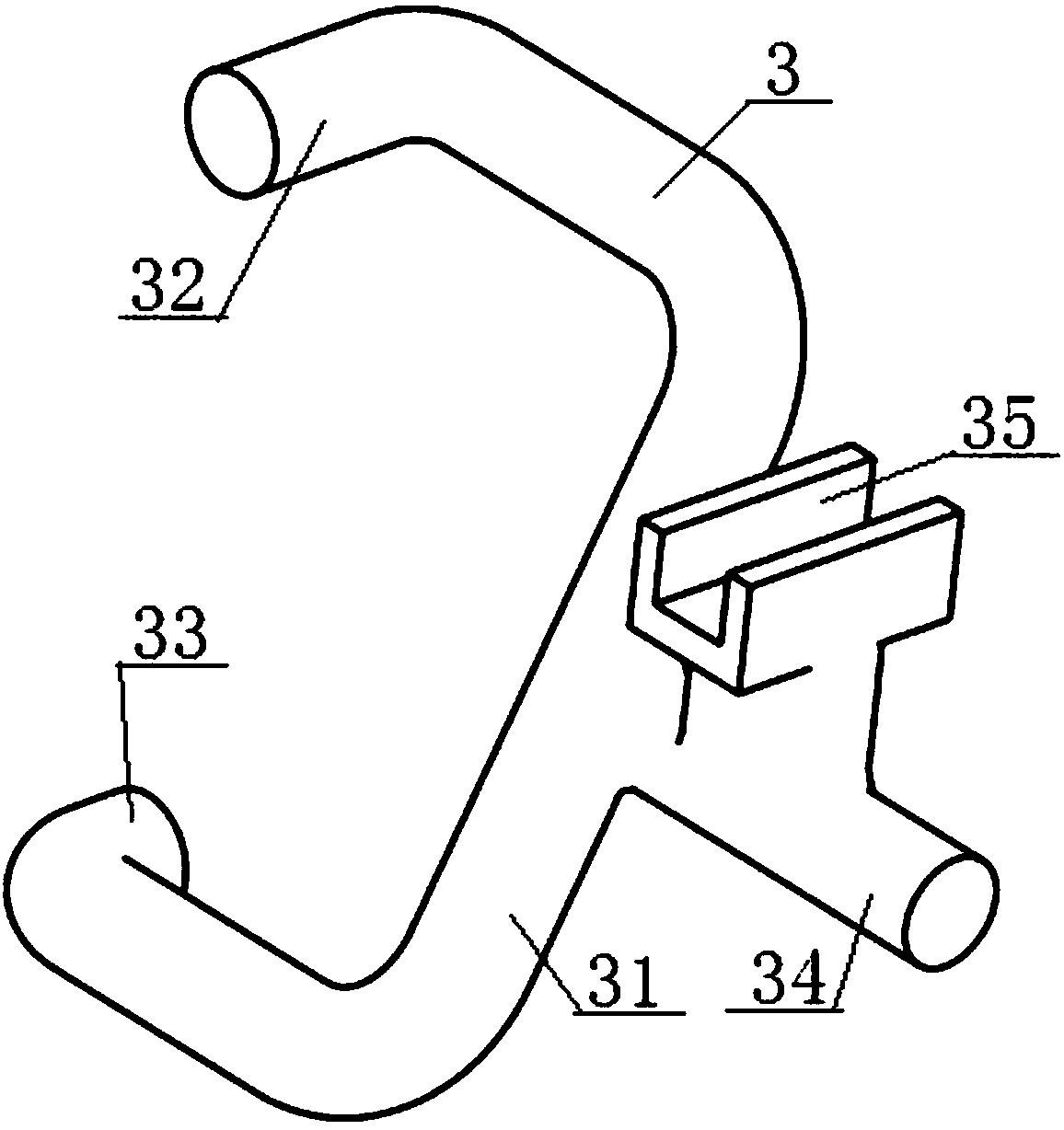

[0072] see Figure 1 to Figure 3, a gearbox overdrive shifting power-assisted shifting mechanism, comprising a gearbox selector shift shaft 1 and a selector shift rocker 2 fixedly connected thereto, one end of the gearbox selector shift shaft 1 passes through the selector shift rocker The arm 2 is in transmission with the shift flexible shaft, and the other end of the transmission selector shaft 1 is in transmission cooperation with the shift fork shaft; the middle part of the selector shift rocker arm 2 is fixedly connected with the transmission selector shift shaft 1, The upper and lower ends of the selector shift rocker arm 2 are in transmission cooperation with the shift fork 3, and the shift fork 3 includes a U-shaped fork lever 31, a general gear selector lever 32 and a direct gear overdrive selector lever 33. Both the general gear selector lever 32 and the direct gear overdrive selector lever 33 are arranged parallel to the gearbox selector shift shaft 1, and one end of...

Embodiment 2

[0086] Embodiment 2 is basically the same as Embodiment 1, and its difference is:

[0087] The end faces of the general gear selector lever 32 and the direct gear overdrive selector lever 33 are both arc-shaped structures.

Embodiment 3

[0089] Embodiment 3 is basically the same as Embodiment 1, and its difference is:

[0090] The shift fork 3 also includes a U-shaped transmission slot 35, the bottom of the U-shaped transmission slot 35 is fixedly connected with the middle part of the transmission push rod 34, and the U-shaped transmission slot 35 is parallel to the gear selection of the gearbox. Shaft 1 is set, and the shift flexible shaft passes through the L-shaped transmission plate 5, the U-shaped transmission groove 35, the transmission push rod 34 and the U-shaped fork rod 31 in sequence; the L-shaped transmission plate 5 includes a vertically connected second A transmission plate 51 and a second transmission plate 52, the end of the first transmission plate 51 is provided with a gear selection flexible shaft installation position 53, and the end of the second transmission plate 52 is provided with a dial block 54, the dial The block 54 is arranged inside the U-shaped transmission groove part 35, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com