Marsh gas storage tank with anti-backfire function

A gas storage tank, anti-backfire technology, applied in gas/liquid distribution and storage, container discharge method, container filling method, etc., can solve problems such as gas storage tank explosion, increase safety, avoid natural phenomena, The effect of avoiding the phenomenon of tempering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

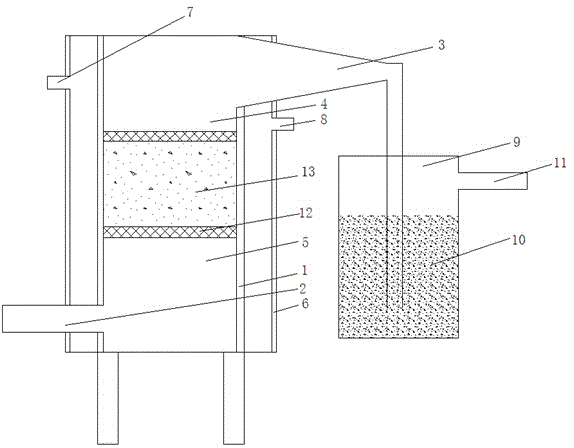

[0014] Such as figure 1 As shown, a biogas storage tank with anti-tempering function of the present invention includes a tank body 1 with an inner cavity, and the tank body 1 is provided with an air inlet pipe 2 and an air outlet pipe 3 communicating with the inner cavity of the tank body 1, The tank body 1 is provided with a desulfurization bed, and the desulfurization bed divides the inner cavity of the tank body 1 into an upper chamber 4 and a lower chamber 5, the air inlet pipe 2 communicates with the lower chamber 5, and the air outlet pipe 3 communicates with the upper chamber 4. The tank wall of the tank body 1 is a heat-insulating tank wall 6 with a cavity. One side of the upper end of the tank wall 6 is provided with a water inlet 7, and the other side is provided with a water outlet 8. The air outlet pipe 3 is also connected to a flame arrester. It includes a flame arrester cavity 9 and a flame retardant material 10 placed in the flame arrester cavity 9, and an exhau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com