Sandwich-structure all-composite-material launching canister

A composite material and sandwich structure technology, applied in the field of launch tubes, can solve the problems of heavy weight and low load-bearing efficiency, and achieve the effect of improving load-bearing efficiency and thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

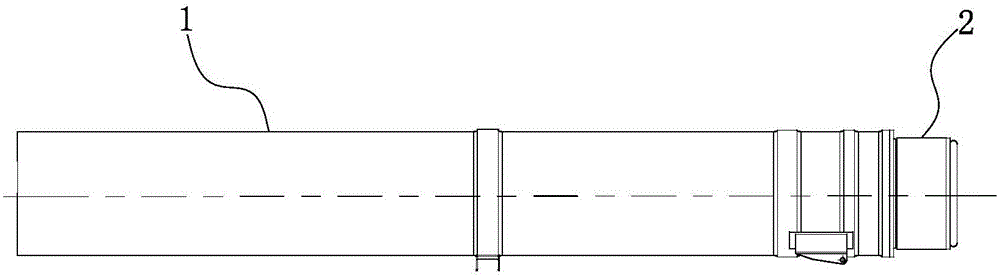

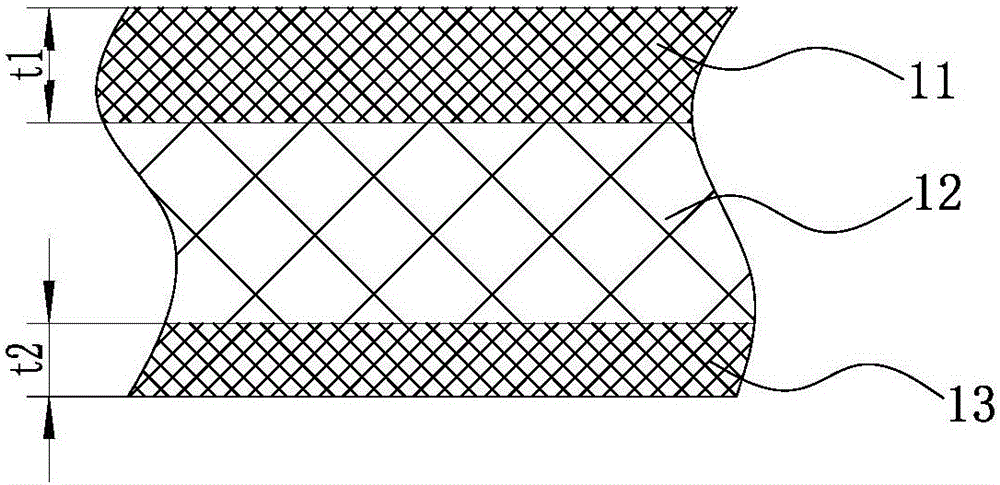

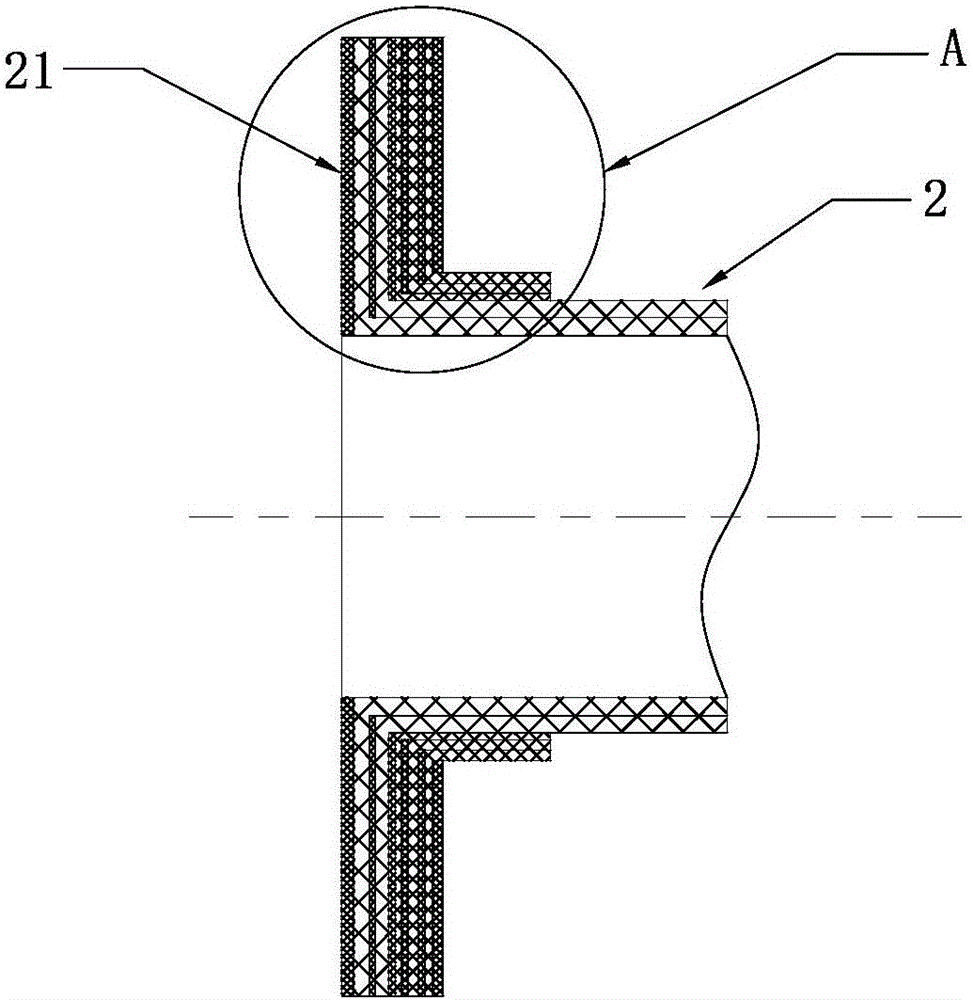

[0026] Such as figure 1 shown, combined with figure 2 As shown, the sandwich-structure full-composite launching tube of the present invention includes a tube section 1 and an initial chamber 2 fixedly connected with the tube section 1, and the tube section 1 includes an inner tube 11, an outer tube 13 and a foam interlayer 12, and the The foam interlayer 12 is located between the inner cylinder 11 and the outer cylinder 13, the materials of the inner cylinder 11 and the outer cylinder 13 are fiber prepreg, and the thickness ratio of the inner cylinder 11 to the outer cylinder 13 is 1.2-1.4.

[0027] The sandwich-structure full-composite launch tube of the present invention, wherein the inner tube 11 and the outer tube 13 are both formed by fiber prepreg layup, and the fiber prepreg layup of the inner tube 11 is set at least one layer, the said The fiber prepreg plies of the outer tube 13 are also at least one layer. In this embodiment, the layers of the inner tube 11 includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com