A mechanical equipment fault automatic identification method based on acoustic image monitoring

A mechanical equipment and automatic identification technology, applied in the direction of measuring devices, machine/structural component testing, instruments, etc., can solve problems such as automatic identification of faults, affecting the popularization and application of acoustic imaging fault detection systems, and lack of automatic identification of faults. Realize the effect of automatic alarm and fault reminder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

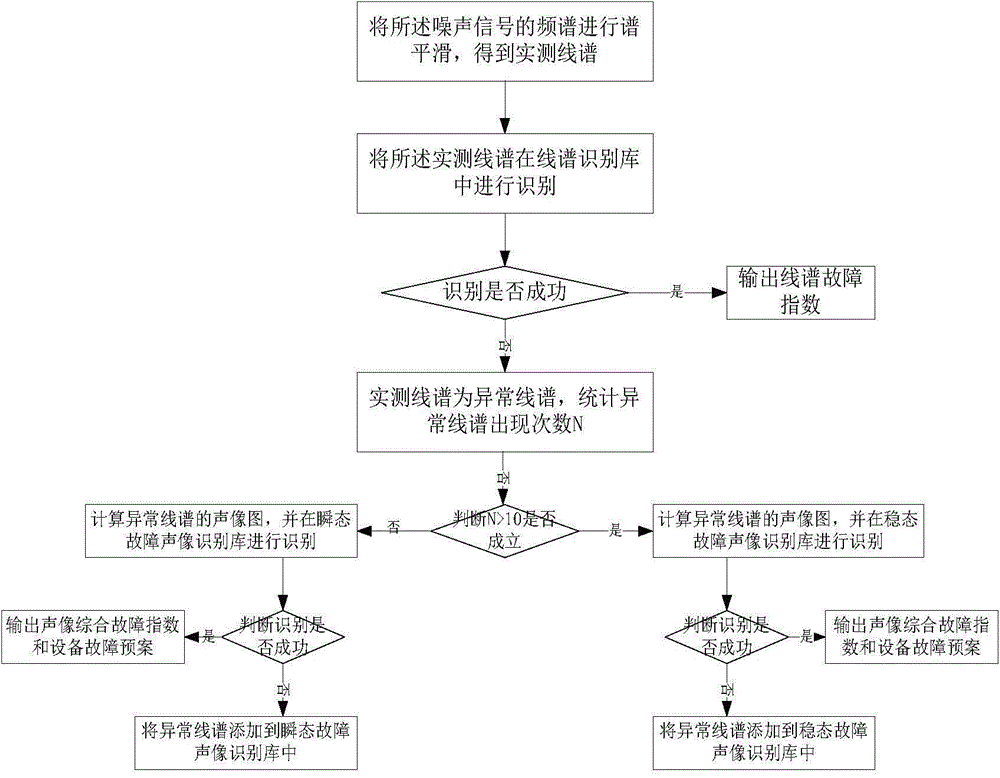

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

[0027] like figure 1 As shown, a method for automatic identification of mechanical equipment faults based on audio-visual monitoring, the method includes:

[0028] Step 1) The acoustic imager monitors the mechanical equipment, collects the noise signal of the mechanical equipment in real time; performs spectrum smoothing on the spectrum of the noise signal to obtain the measured line spectrum;

[0029] Before said step 1), under the normal and stable working conditions of the mechanical equipment, set up a mechanical equipment line spectrum identification library, a mechanical equipment steady-state fault audio-visual library and a mechanical equipment transient fault audio-visual library; specifically include:

[0030] Establish a mechanical equipment line spectrum identification library: when the mechanical equipment is working normally and stably, measure the frequ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com