Knock Sensor Load Simulator

A knock sensor, simulator technology, applied in the direction of instrument, test/monitor control system, control/regulation system, etc., can solve the problems of loss, risk or defect can not be exposed, can not cover the reliability verification of drive or load circuit, etc. To achieve a wide range of applications, large practical application value, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

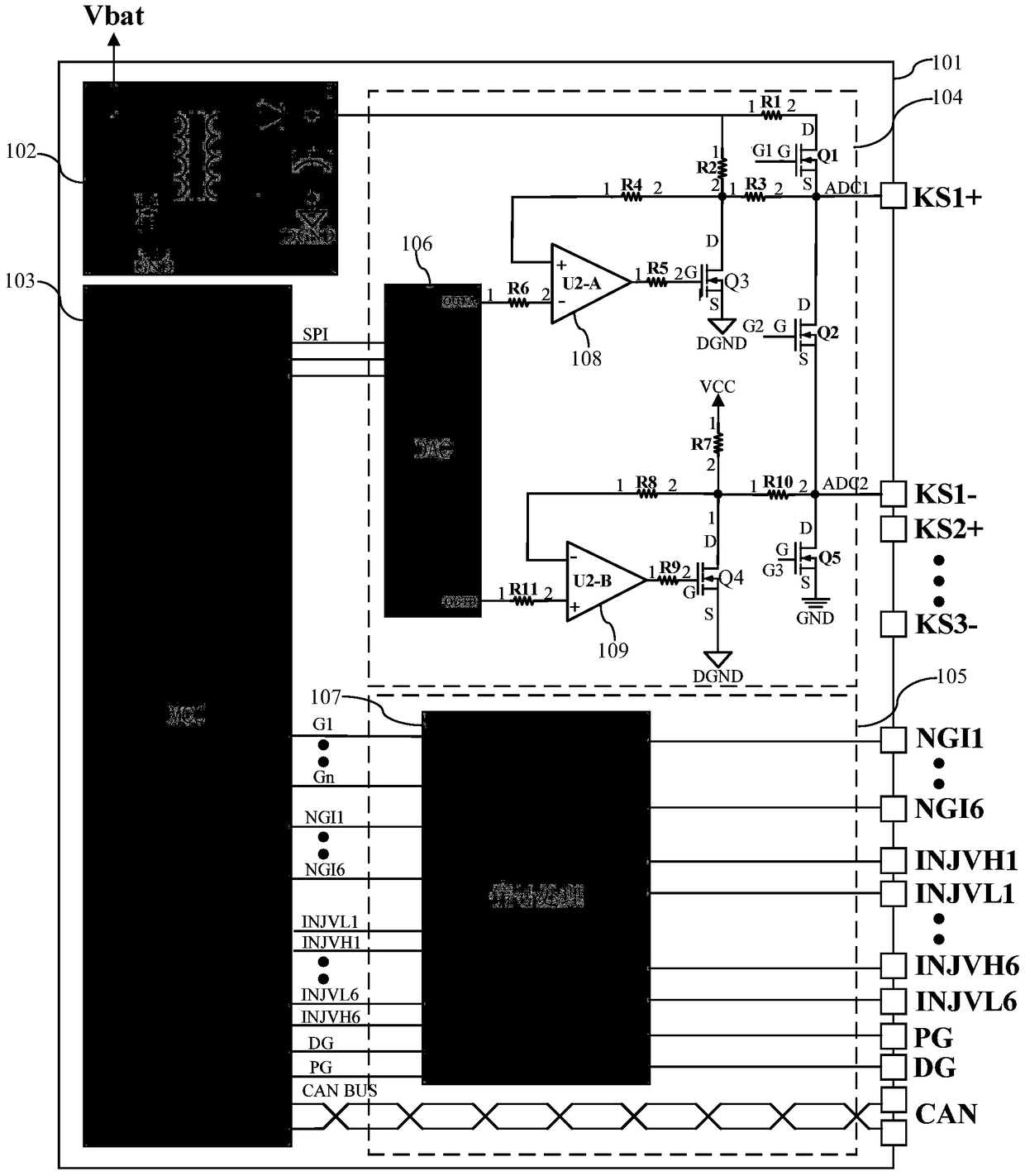

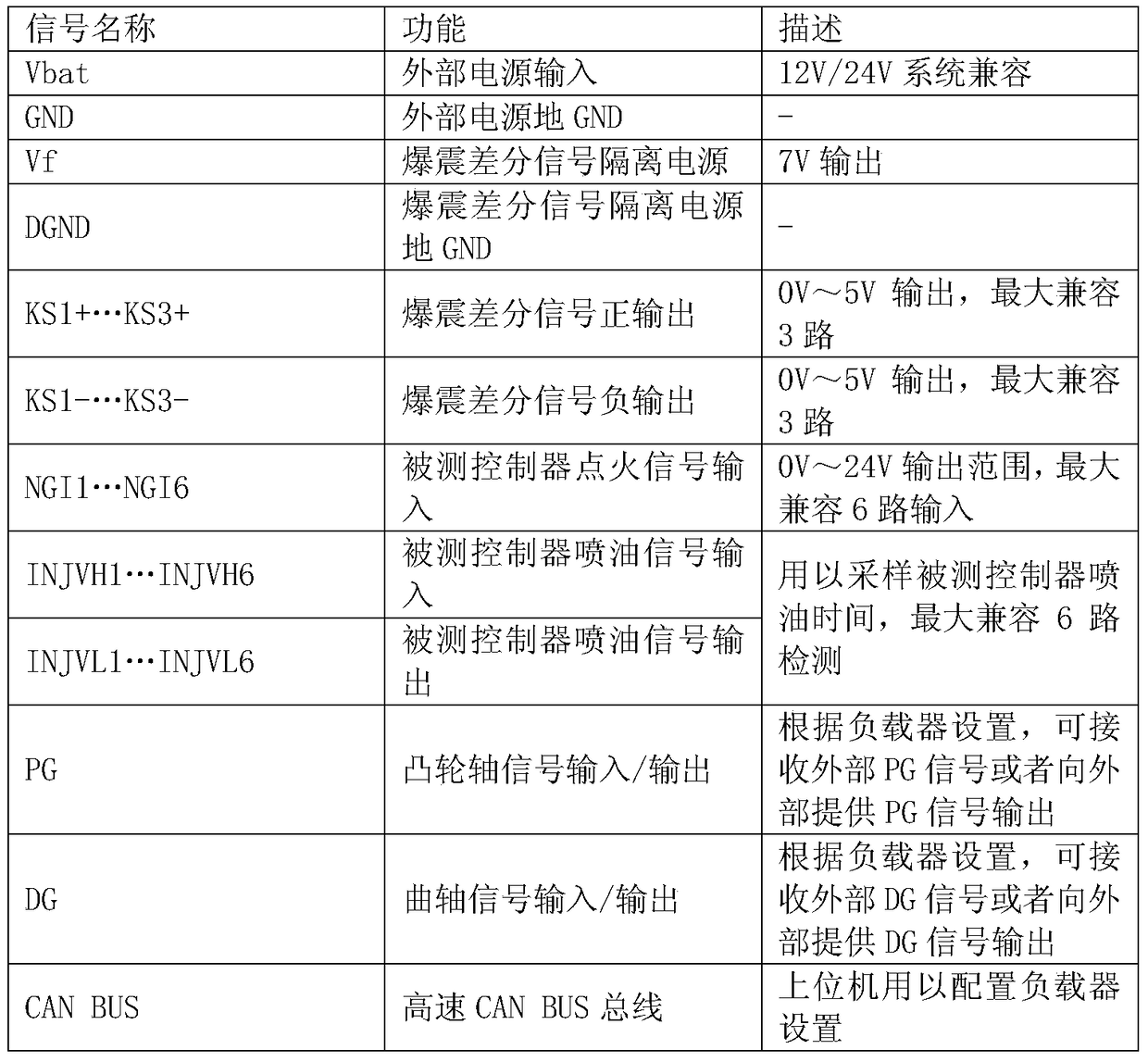

[0033] Such as figure 1 As shown, it is a schematic structural diagram of a knock sensor load emulator in an embodiment of the present invention. The knock sensor load emulator 101 in an embodiment of the present invention is used to provide a knock signal for the electronic controller of a vehicle under test. The knock sensor load emulator 101 It includes: a power supply module 102, a processor module 103, a knock sensor simulation output module 104, and a signal processing module 105.

[0034] The power supply module 102 provides power for the knock sensor simulation output module 104 . At present, the traditional automobile system is divided into two major systems of 12V / 24V, and the power module 102 is compatible with the voltage input of the two major automobile systems of 12V and 24V, that is, the input voltage Vbat of the power module 102 is 12V or 24V. The power supply module 102 provides a 7V isolated power supply for the knock sensor simulation output module 104 , a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com