A method for on-line detection and evaluation of fuel collision

A technology of fuel oil and injection holes, which is applied in the direction of instruments, geometric CAD, calculation, etc., can solve the problem of no online detection function of fuel collision, and achieve the effect of avoiding oil dilution, avoiding fuel collision, and ensuring real-time performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

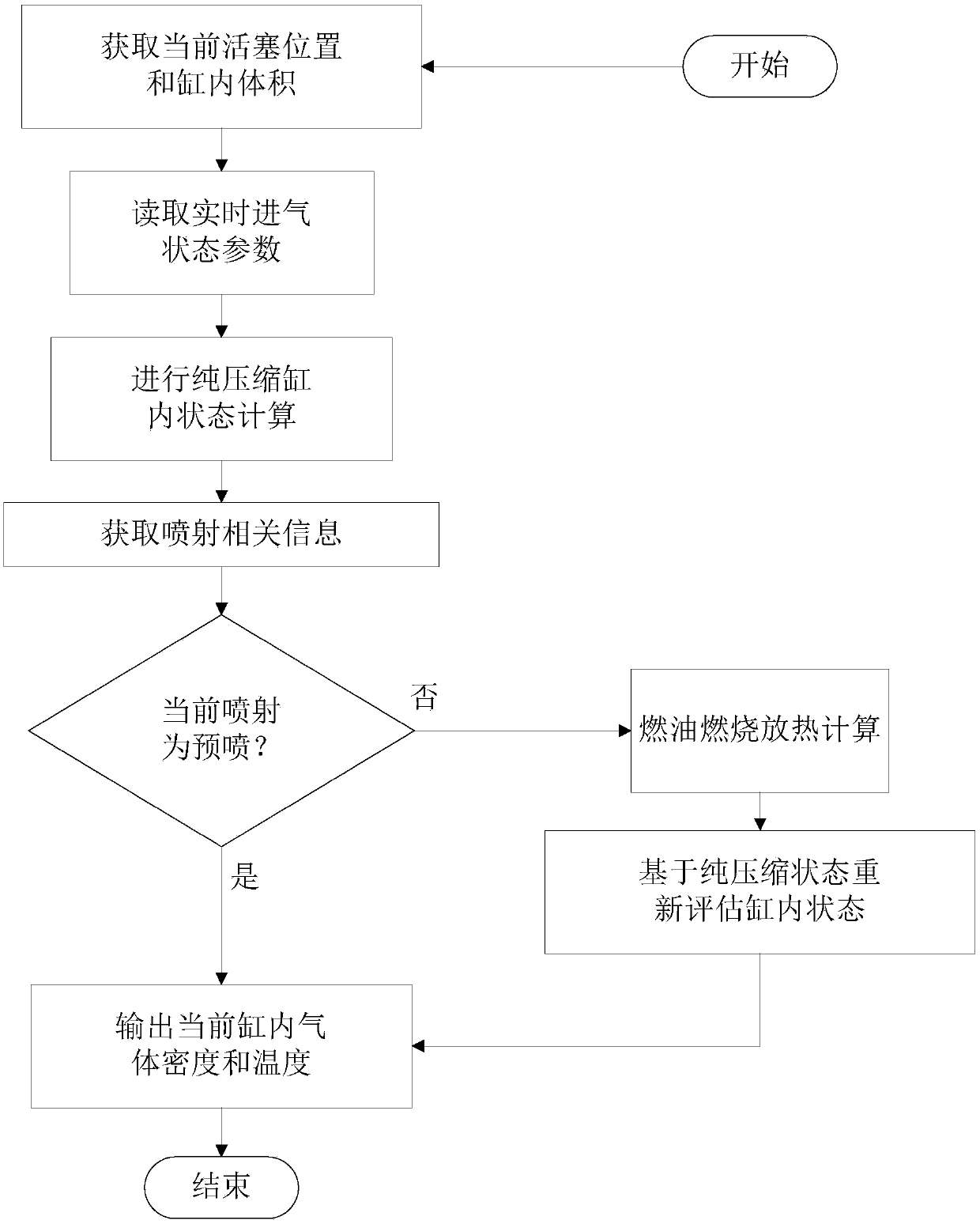

[0041] This specific embodiment provides an online detection and evaluation method for fuel collision, which can accurately evaluate fuel collision in real time.

[0042] Hereinafter, an embodiment will be described with reference to the drawings. In addition, the examples shown below do not limit the content of the invention described in the claims in any way. In addition, all the contents of the configurations shown in the following embodiments are not limited to be essential to the solutions of the invention described in the claims.

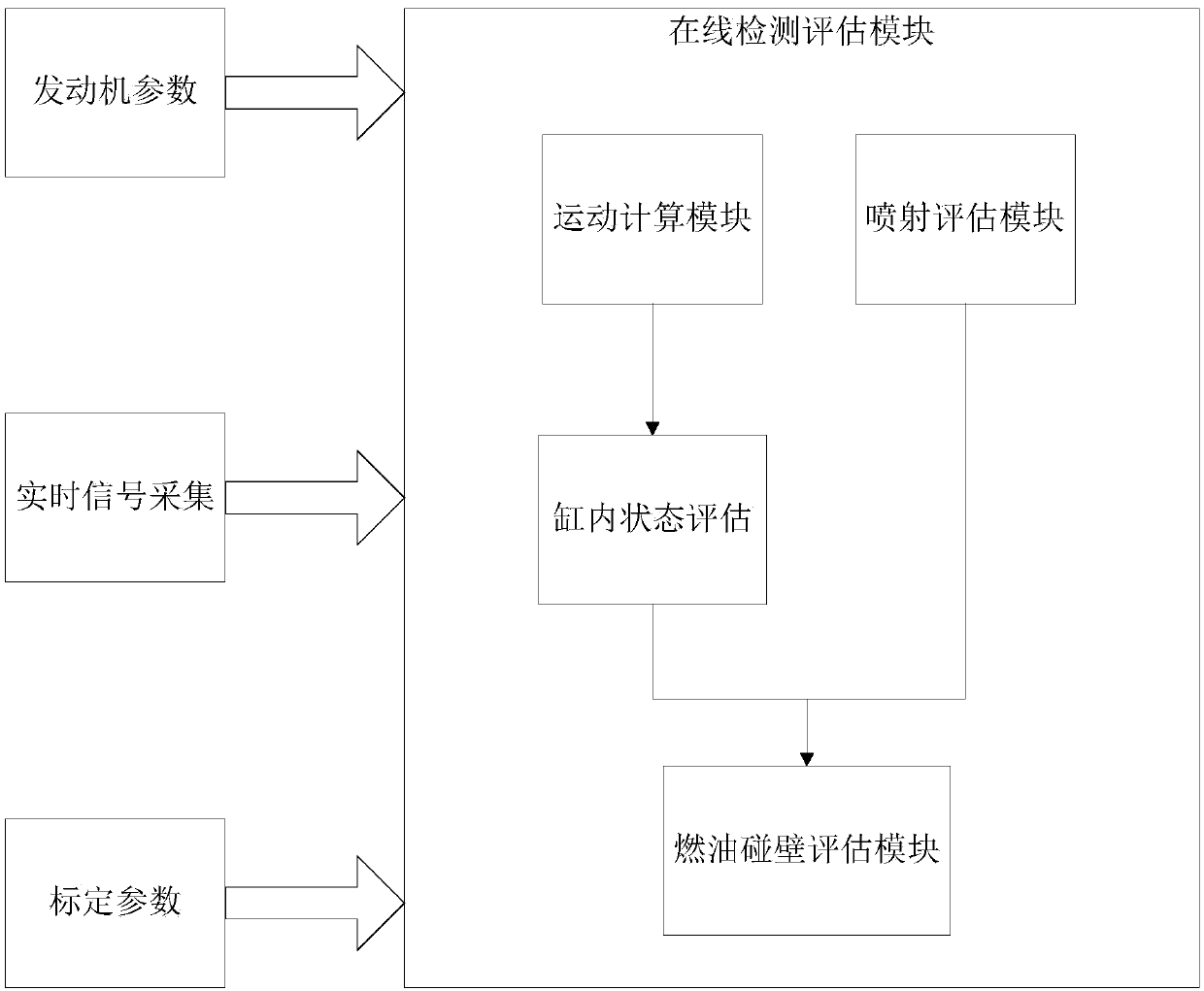

[0043] The overall flow diagram provided in this embodiment, such as figure 1 shown. The fuel collision online detection and evaluation method provided in this embodiment requires three types of input: engine parameters, engine real-time running signals and user calibration parameters. The fuel collision online detection and evaluation module formed by the fuel collision online detection and evaluation method can include four types. Three s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com