A super high voltage power output circuit

An ultra-high voltage and power output technology, applied in the direction of irreversible DC power input conversion to AC power output, output power conversion device, electrical components, etc., to achieve high energy, avoid damage, and reduce reflection stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

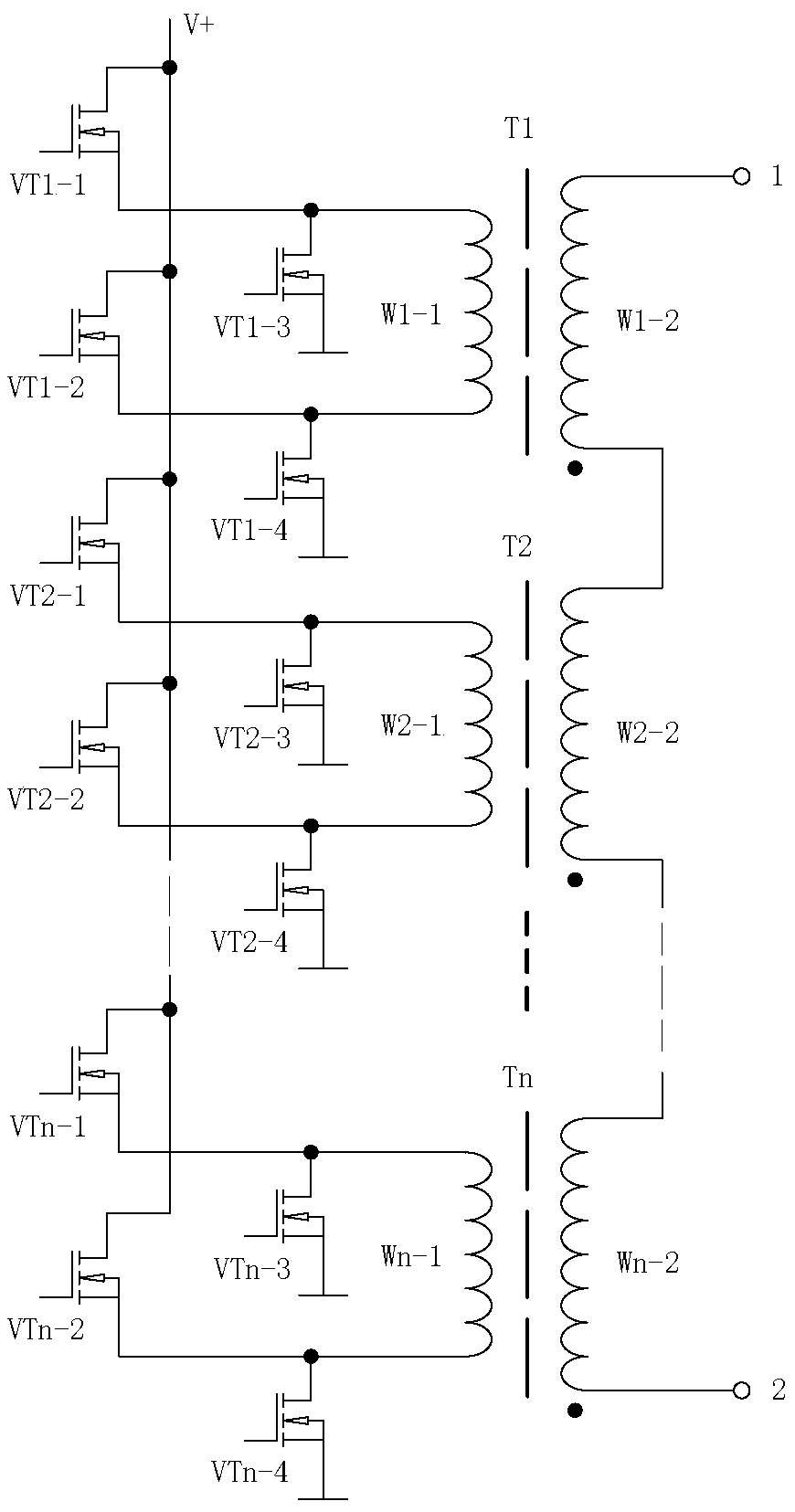

[0017] Example 1 figure 1 In the embodiment shown, an ultra-high voltage power output circuit consists of the upper left switch tube (VT1-1) of the first power boost circuit, the upper right switch tube (VT1-2) of the first power drive circuit, the first power The left switch tube (VT1-3) of the push circuit, the right switch tube (VT1-4) of the first power drive circuit, the upper left switch tube (VT2-1) of the second power drive circuit, the upper right switch of the second power drive circuit tube (VT2-2), the left switch tube (VT2-3) of the second power push circuit, the right switch tube (VT2-4) of the second power drive circuit, the upper left switch tube (VTn-1) of the nth power drive circuit ), the upper right switch tube (VTn-2) of the nth power boosting circuit, the left switch tube (VTn-3) of the nth power boosting circuit, the right switch tube (VTn-4) of the nth power boosting circuit and multiple high voltage Composed of transformer units, wherein the high-volt...

Embodiment 2

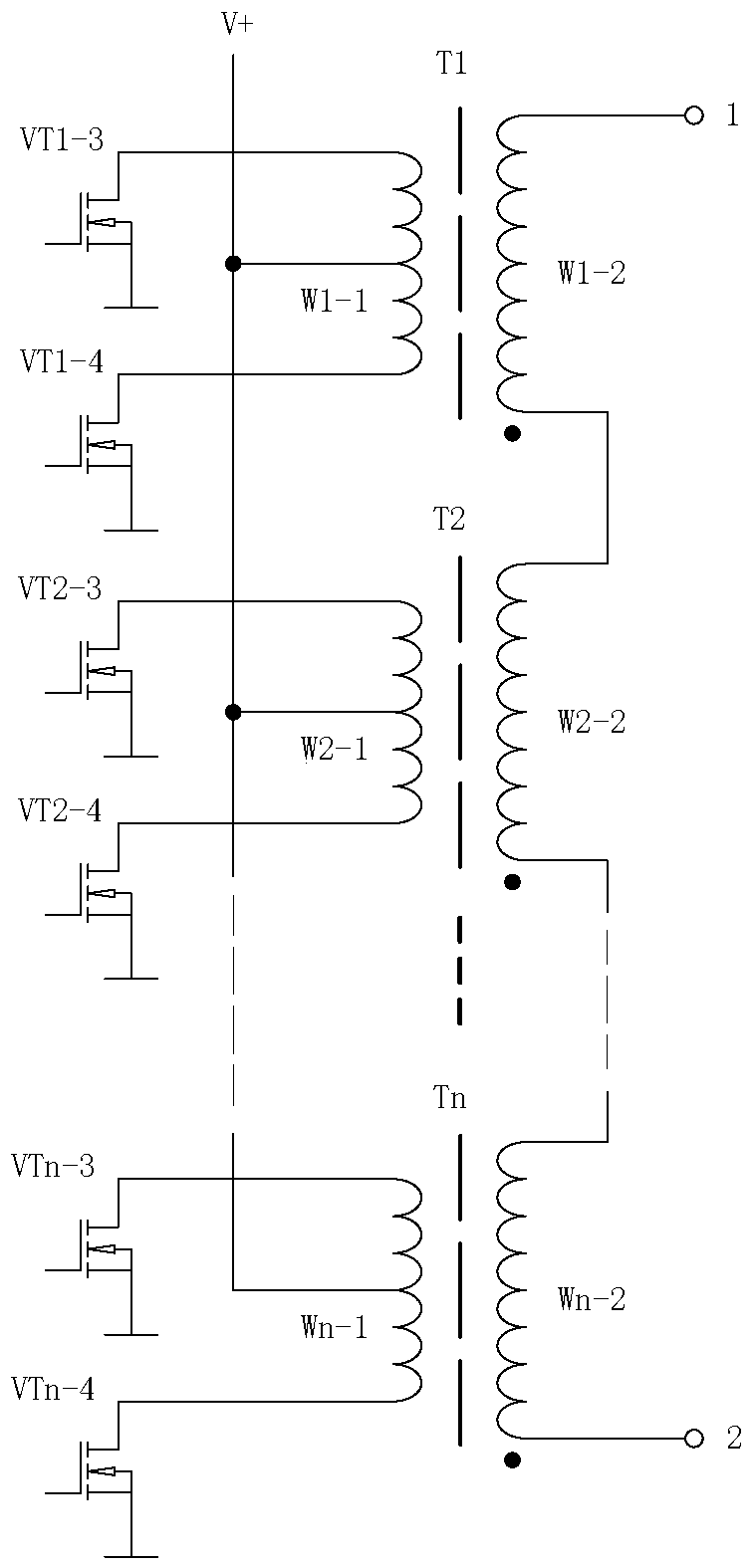

[0018] Example 2 figure 2 In the embodiment shown, another ultra-high voltage power output circuit consists of the left switch tube (VT1-3) of the first power push circuit, the right switch tube (VT1-4) of the first power push circuit, the second The left switch tube (VT2-3) of the power push circuit, the right switch tube (VT2-4) of the second power drive circuit, the left switch tube (VTn-3) of the nth power drive circuit, and the right switch tube (VTn-3) of the nth power drive circuit The switch tube (VTn-4) is composed of a plurality of high-voltage transformer units, wherein the structure of the high-voltage transformer is the same as that of the first embodiment, and will not be repeated here. The primary coil of each high-voltage transformer unit adopts a center tap method, the drain of the left switch tube is connected to the left end of the primary coil of the high-voltage transformer unit, the drain of the right switch tube is connected to the right end of the prim...

Embodiment 3

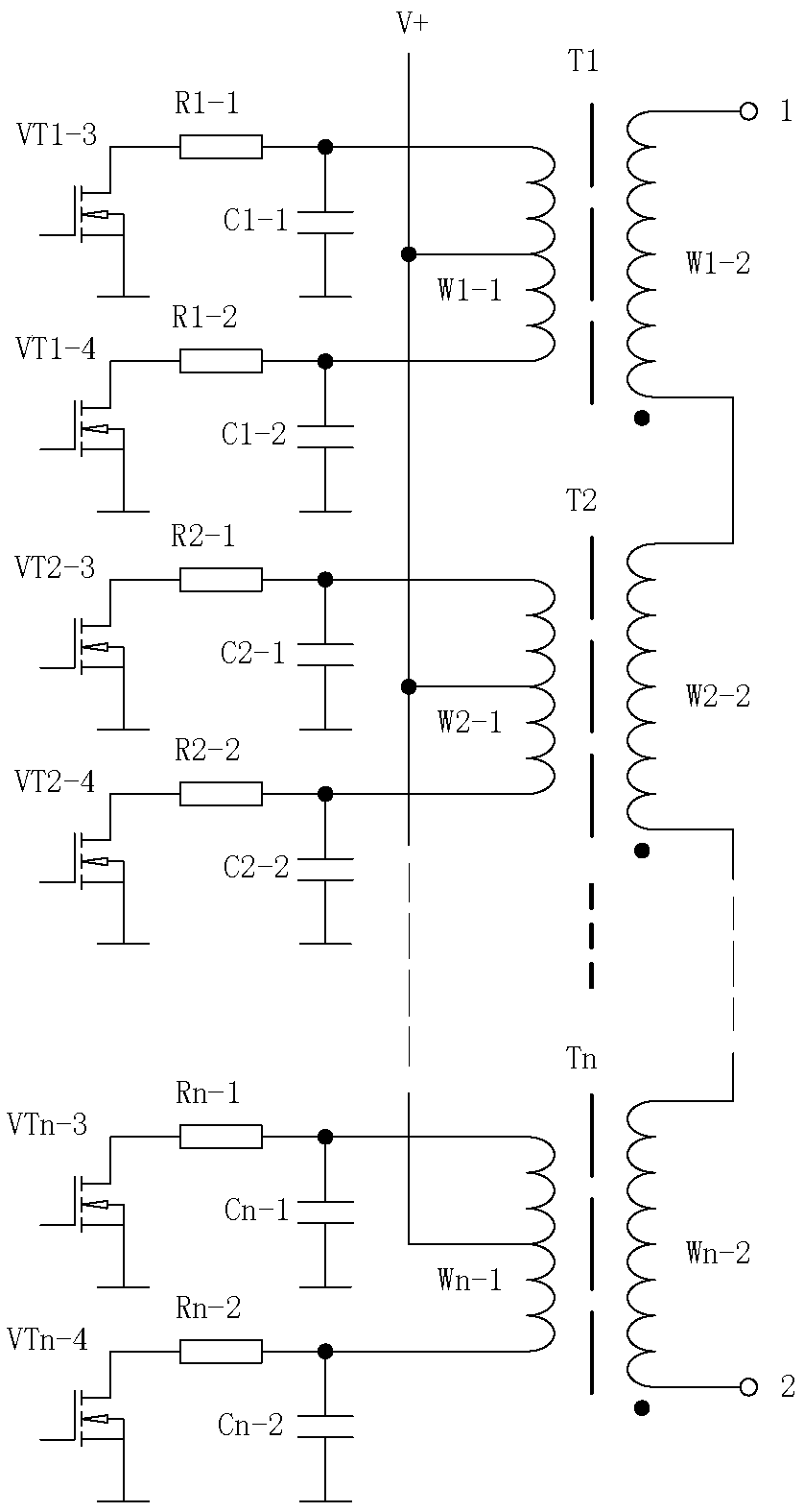

[0019] Example 3 image 3 In the embodiment shown, another ultra-high voltage power output circuit is based on the first embodiment or the second embodiment, and there is a left absorbing capacitor between the left end of the primary coil of the high-voltage transformer unit and the ground wire, There is a right absorption capacitor between the right end of the primary coil of the high-voltage transformer unit and the ground wire; there is a left current-limiting resistor between the drain of the left switch tube and the left end of the primary coil of the high-voltage transformer unit, and between the drain of the right switch tube and the high voltage There is a right current limiting resistor between the right ends of the primary coil of the transformer unit. In this implementation, current-limiting resistors and absorbing capacitors are set in the circuit to avoid damage to switching devices when outputting high power. Other structures are the same as those of the first e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com