Multi-transformer combined ultrahigh voltage generation device

An ultra-high voltage, generating device technology, applied in transformers, transformers/inductor coils/windings/connections, circuits, etc., to achieve the effects of reducing reflection stress, high efficiency, and increasing output voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

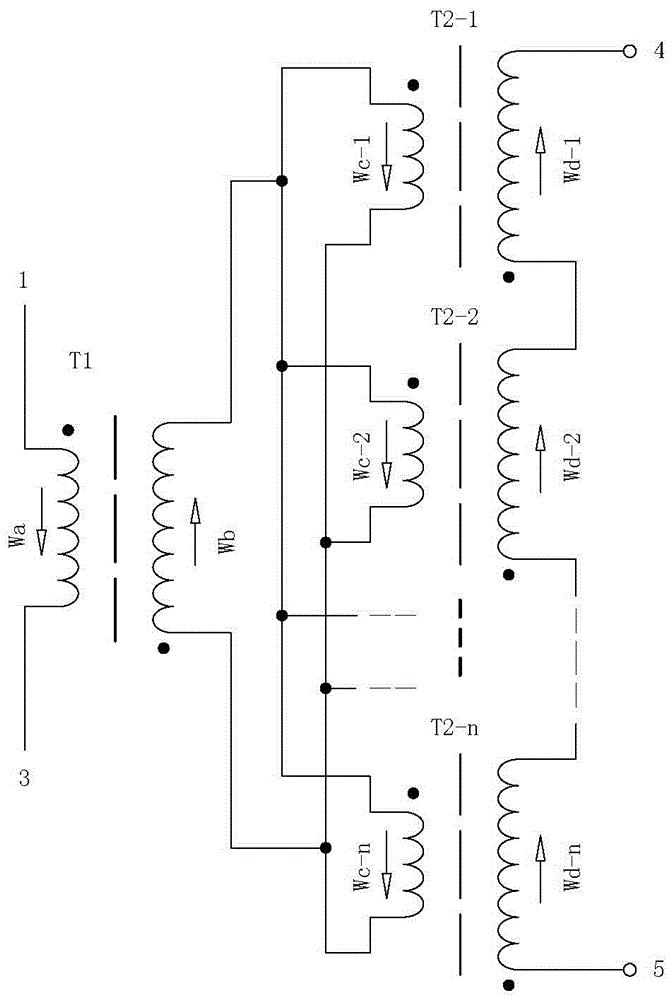

[0019] Example 1 figure 1 In the illustrated embodiment, the multi-transformer combination ultra-high voltage generator consists of an intermediate transformer unit (T1) and multiple high-voltage transformer units, wherein the intermediate transformer unit (T1) includes a primary side coil (Wa) and a secondary side coil (Wa) The coil (Wb), the primary side coil (Wa) and the secondary side coil (Wb) are nested, and the primary side coil (Wa) is set in the inner layer; the high voltage transformer unit includes the primary coil and the secondary high voltage coil, the primary coil and The secondary high-voltage coils are nested, the secondary high-voltage coils are set on the outer layer, and the secondary high-voltage coils are wound on the skeleton in a lattice winding manner; the primary coils of multiple high-voltage transformer units are connected in parallel with the end of the same name Afterwards, the primary-side electrical circuit is formed, and the secondary high-v...

Embodiment 2

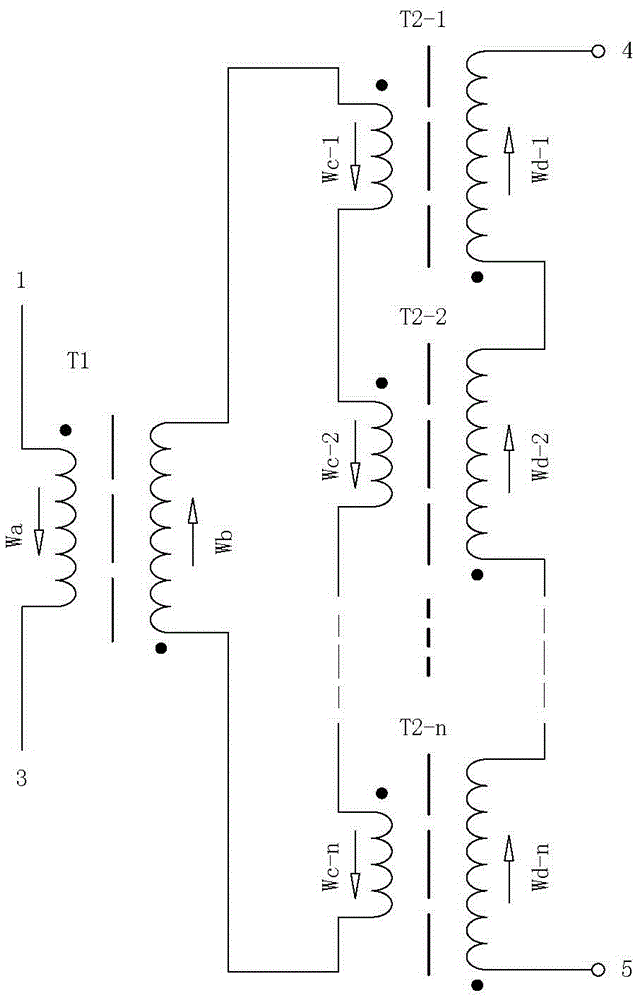

[0020] Example 2 figure 2 In the illustrated embodiment, the multi-transformer combination ultra-high voltage generator consists of an intermediate transformer unit (T1) and multiple high-voltage transformer units, wherein the intermediate transformer unit (T1) includes a primary side coil (Wa) and a secondary side coil (Wa) The coil (Wb), the primary side coil (Wa) and the secondary side coil (Wb) are nested, and the primary side coil (Wa) is set in the inner layer; the high voltage transformer unit includes the primary coil and the secondary high voltage coil, the primary coil and The secondary high-voltage coils are nested, the secondary high-voltage coils are arranged on the outer layer, and the secondary high-voltage coils are wound on the skeleton in a lattice winding manner; the primary coils of each high-voltage transformer unit are connected in series in the forward direction. The primary side electrical circuit is formed, and the secondary high voltage coils of e...

Embodiment 3

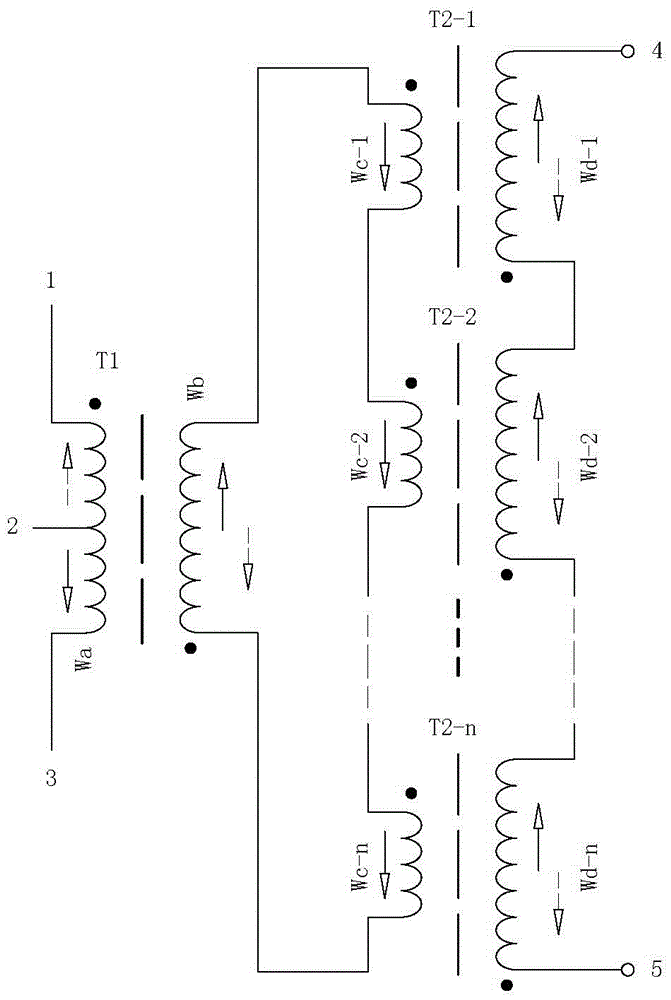

[0021] Example 3 image 3In the embodiment shown, the multi-transformer combined ultra-high voltage generating device is based on the second embodiment, the primary side coil (Wa) in the intermediate transformer unit (T1) has a center tap (2), and the center Tap (2) is used to connect the input power. Other structures are the same as those of the second implementation, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com