A power output circuit of a high voltage power supply

A power output, high-voltage power supply technology, applied in the direction of electrical components, accelerators, etc., to achieve the effect of increasing output voltage, reducing reflection stress, and avoiding damage to switching devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

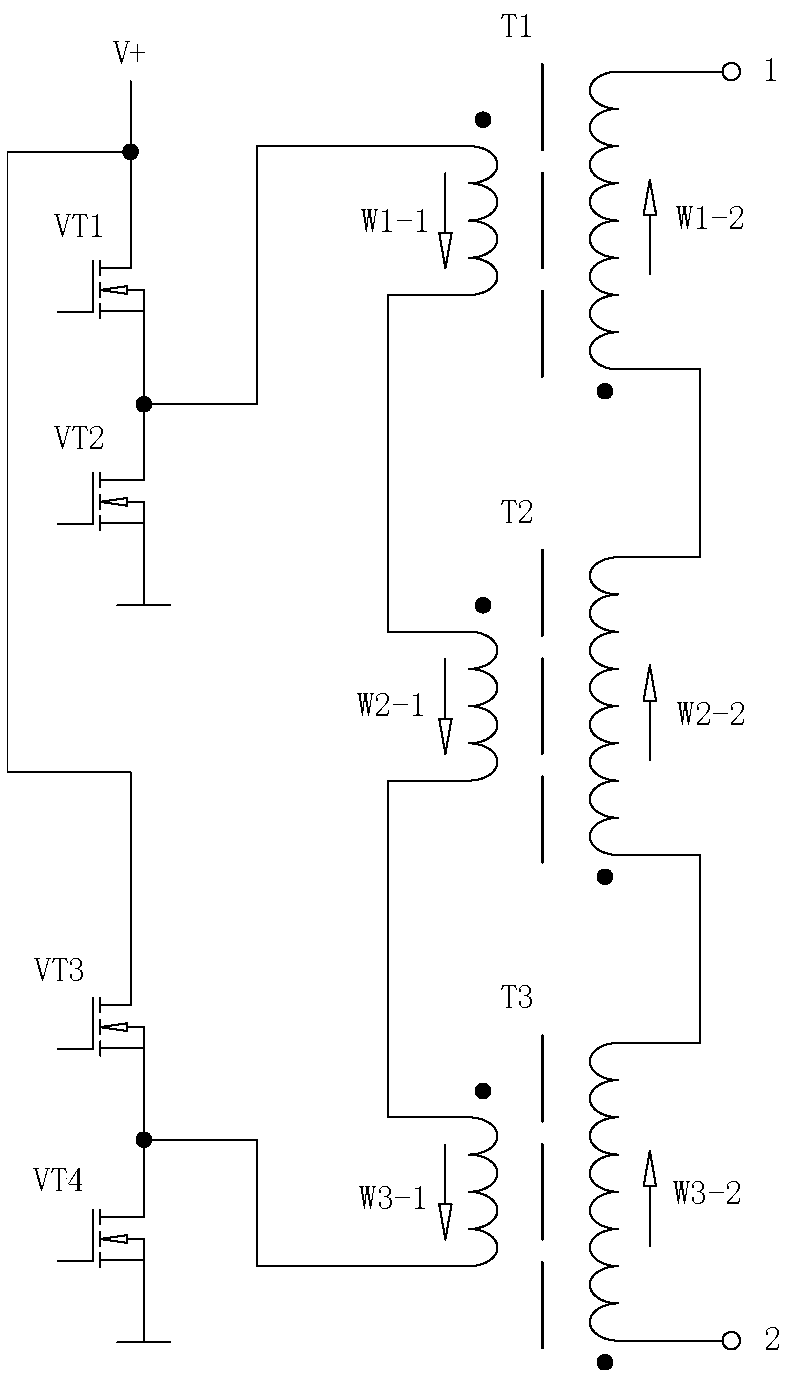

[0015] Example 1 figure 1 In the illustrated embodiment, the power output circuit of a high-voltage power supply consists of a first power switch tube (VT1), a second power switch tube (VT2), a third power switch tube (VT3), and a fourth power switch tube (VT4). ) And multiple high-voltage transformer units. The high-voltage transformer unit is composed of a primary coil and a secondary high-voltage coil. The primary coil and the secondary high-voltage coil of the same high-voltage transformer unit are nested, the primary coil is set in the inner layer, and the secondary The high-voltage coil is arranged on the outer layer, and the secondary high-voltage coil is wound on the skeleton in a grid winding manner; there are more than two high-voltage transformer units, and the primary coils of multiple high-voltage transformer units are connected in series to form a primary low-voltage circuit. The secondary high-voltage coils of the transformer unit are connected in series to form a...

Embodiment 2

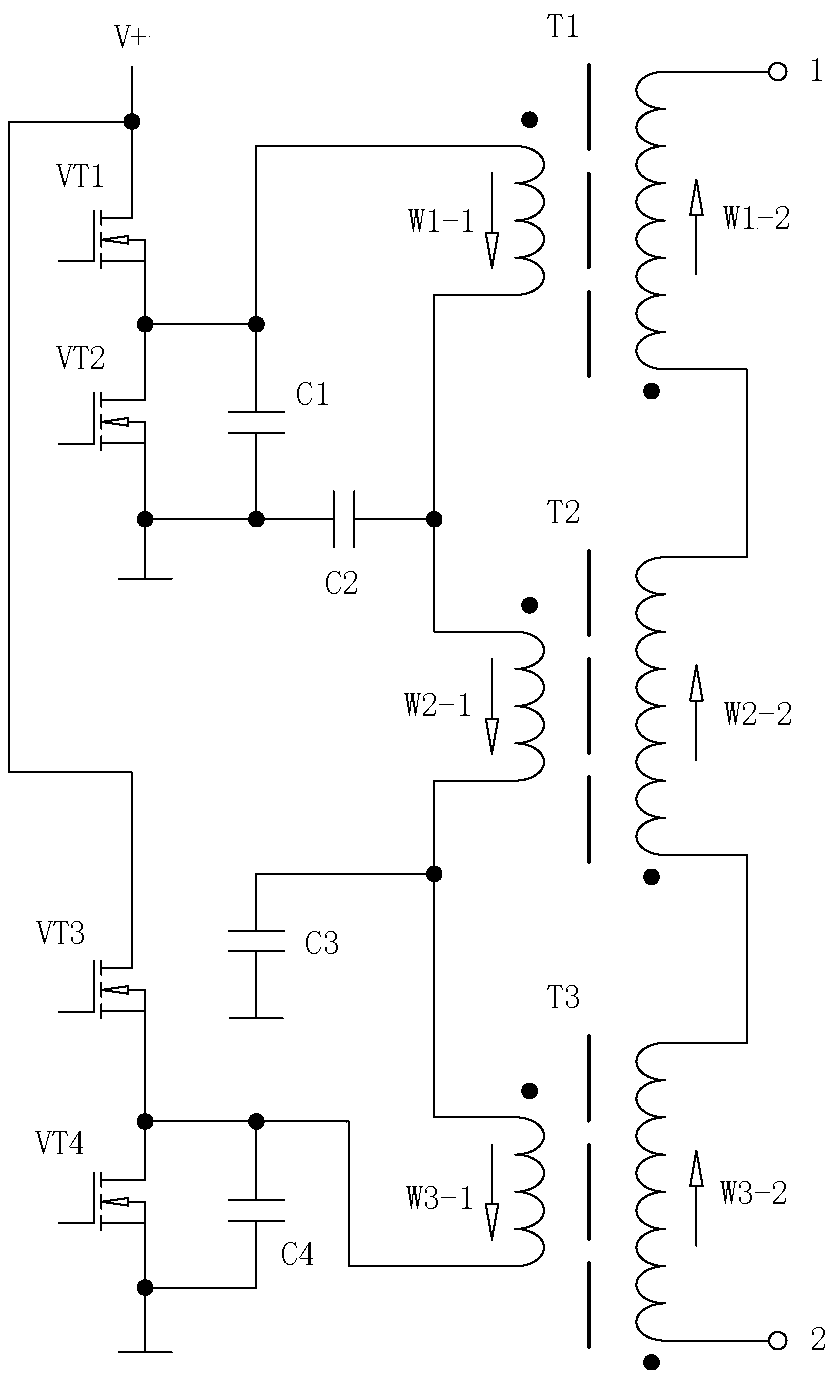

[0016] Example 2 figure 2 In the illustrated embodiment, on the basis of the first embodiment, the connection line of the primary coils of two adjacent high-voltage transformer units, the head end of the primary low-voltage circuit and the tail end of the primary low-voltage circuit are each demagnetized. The capacitor is connected to the ground wire, and the demagnetization capacitor is charged during the off period of the first power switch tube (VT1), the fourth power switch tube (VT4), the third power switch tube (VT3), and the second power switch tube (VT2). , Make the primary side of each high-voltage transformer generate demagnetization current, reset the magnetic flux in each high-voltage transformer, thereby improving efficiency and avoiding damage to switching devices. The other structure is the same as that of the first embodiment, and will not be repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com