Oven door of rotational molding machine oven

A technology of rotomolding machines and ovens, which is applied in the direction of windows/doors, door/window protection devices, shutters/movable grilles, etc., which can solve the problems of very high requirements for the size of the work site, large volume of the oven, and large occupied space. Achieve the effect of solving the problem of large space occupation, improving work efficiency, and convenient installation and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

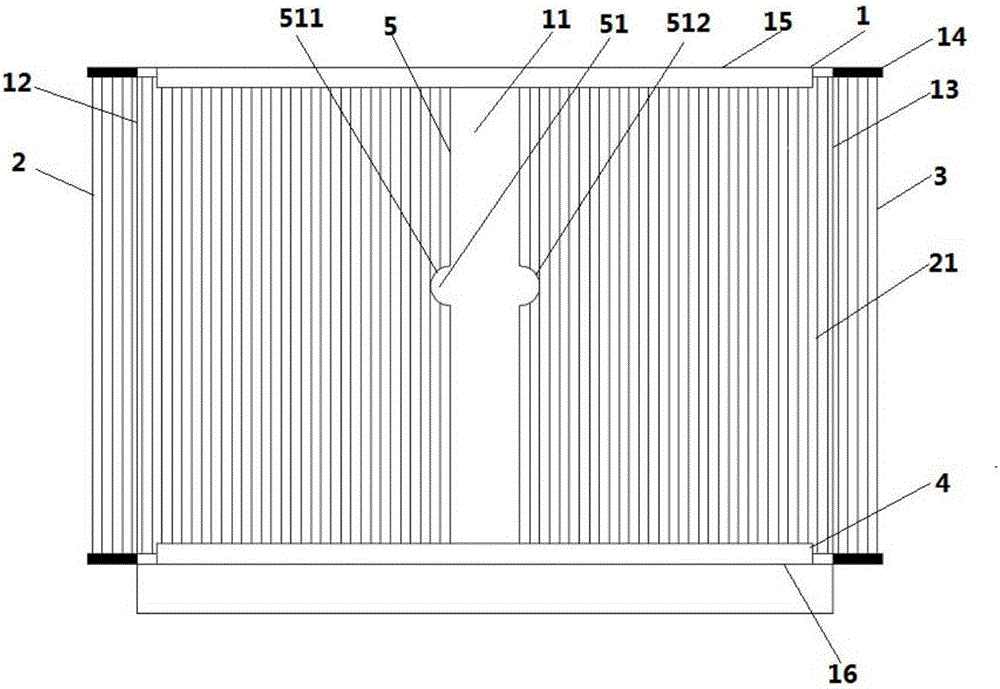

[0015] An oven door of a rotomolding machine, comprising a box body 1, the front side of the box body 1 is set as a box opening 11, and the mold connected to the rotating arm of the rotomolding machine passes through the box opening from the front side of the box body 1 11 stretches into the box body 1, and the top and bottom ends of the box body 1 left plate 12 and right plate 13 outer surfaces at the box mouth 11 are provided with brackets 14 perpendicular to the left plate 12 and the right plate 13, and the left plate 12 and the right plate 13 are vertically arranged. A left-hand roll gate 2 is provided between the supports 14 on the plate 12, a right-hand roll gate 3 is provided between the supports 14 on the right plate 13, and a groove is provided on the top plate 15 and the bottom plate 16 of the box body 1 at the box mouth 11. The guide groove 4 opposite to the mouth, the curtains 21 of the left rolling gate 2 and the right rolling gate 3 are respectively inserted into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com