Special stratum spin-digging pile hole-forming construction method

A construction method and technology of rotary excavation piles, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of low construction difficulty and achieve the effects of improving construction efficiency, simple operation, and reasonable design of construction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

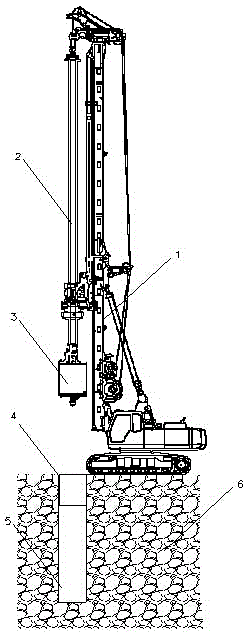

[0034] see now figure 1 , figure 1 It is a schematic diagram of forming a hole with a rotary-dug pile in a special formation according to an embodiment of the present invention.

[0035] The construction method of the special formation rotary-dug pile of the present invention uses a rotary drilling rig to be used for the stratum of sand layer, clay layer, crushed pebble layer, hard rock and silt, and is characterized in that comprising the following steps:

[0036] a. Positioning and setting out, use the total station to determine the position of the stake point, align the drill bit of the rotary drilling rig with the center of the pile position, and the deviation of the pile position shall not exceed 10mm;

[0037] b. Bury the casing, the casing should be buried with clay, and layered and symmetrically rammed; the buried casing is aimed at the silt formation, sand layer, and broken pebbles that are easy to collapse, and the guiding function needs to be strengthened or the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com