An insulated hanging ladder specially used for equipotential operation

An equipotential and working technology, applied in the direction of ladders, overhead lines/cable equipment, buildings, etc., can solve problems such as the inability of operators to control the direction of rotation, the inability of potential transfer rods to hang and place, and the long time to ride on the elevator. Work safety, ease of work safety, and the effect of improving ride comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

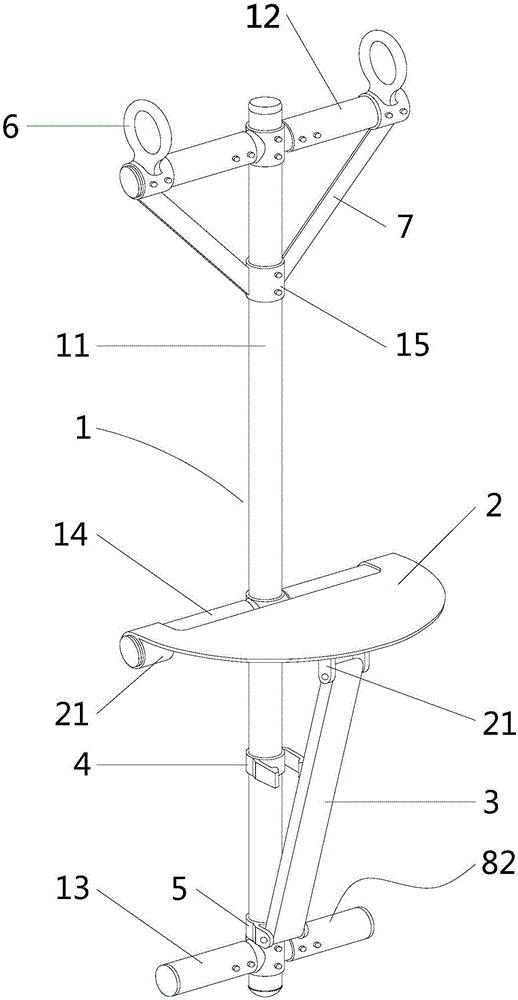

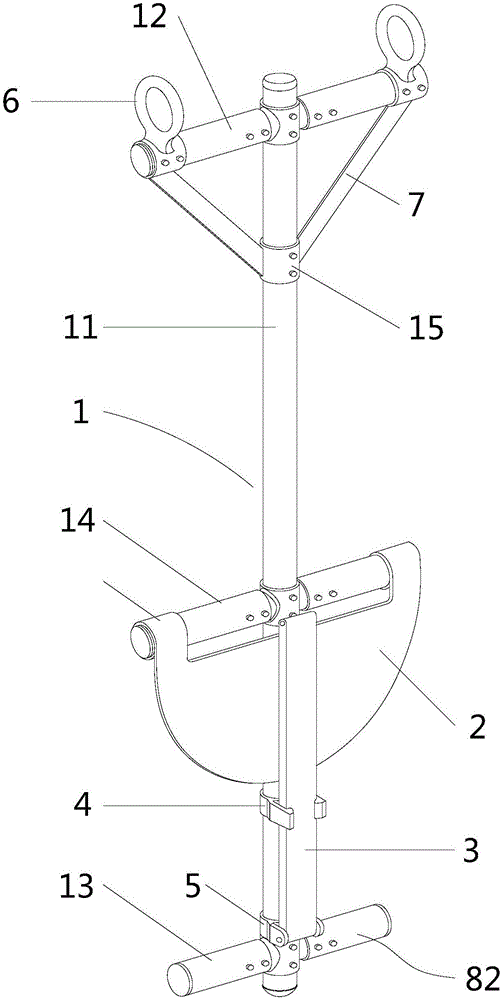

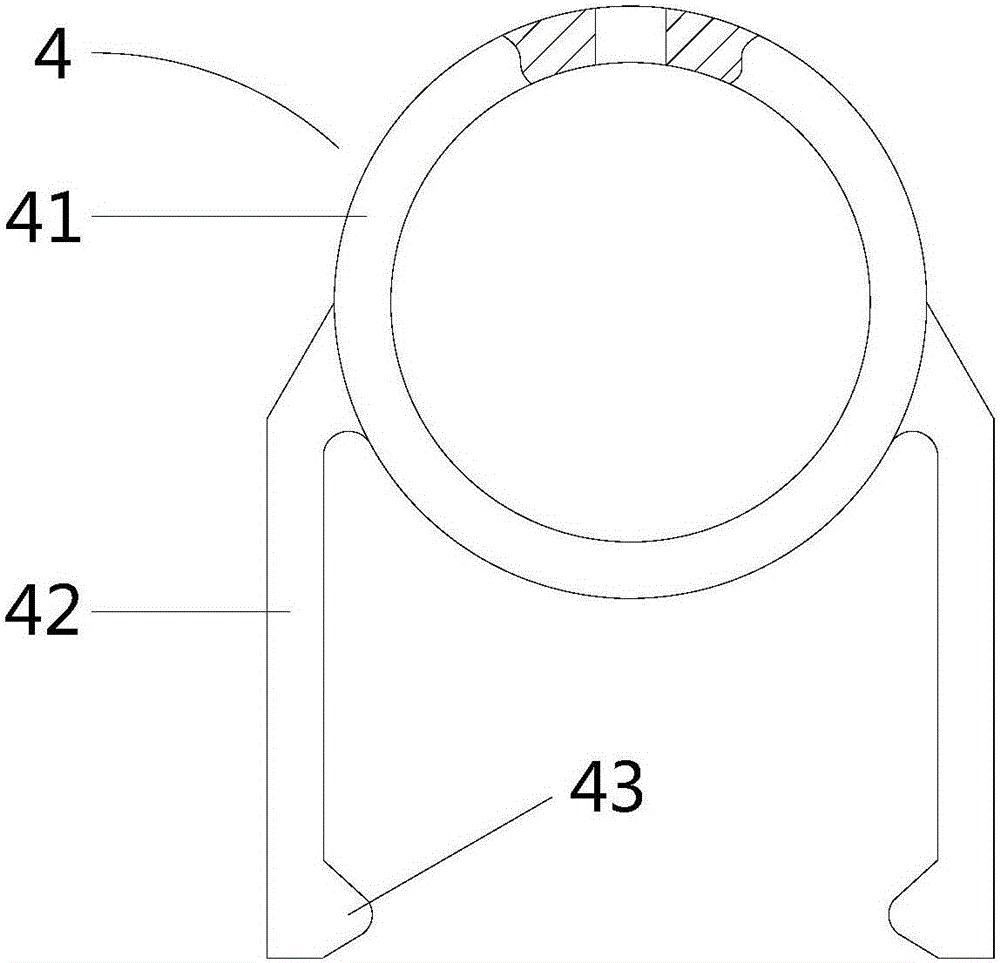

[0037] Such as figure 1 , 2 As shown, the special insulation hanging ladder for equipotential work provided by the embodiment of the present invention includes a base frame 1, a stool 2 for riding and a support rod 3 for supporting the stool 2, and one side of the stool 2 is rotatably connected to the The base frame 1, one end of the support rod 3 is rotatably connected to the base frame 1 and is located below the connection between the stool and the base frame, and the other end of the support rod 3 cooperates with the stool board 2 to fix and support the stool board during use.

[0038] The base frame 1 is in the shape of a "king" or a "non" and includes a vertical rod 11, a top rod 12 arranged at the top of the vertical rod, a bottom rod 13 arranged at the bottom of the vertical rod, and a bottom rod between the top and the bottom of the vertical rod. The cross bar 14 , in this embodiment, the cross bar 14 is arranged at the middle part of the vertical bar 11 or at a posit...

Embodiment 2

[0053] The difference between this embodiment and the above-mentioned embodiment 1 is that the thickness of the stool board 2 is relatively large, and the bottom surface of the stool board is provided with a draw-in groove on the side away from the base frame 1 to cooperate with the top of the support rod 3. When the support rod 3 is in use The supporting stool 2 is fixed through the cooperation of the top end and the draw-in groove.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com