Car light spiral optical guide tooth

A technology of light guide teeth and spiral shape, which is applied in the processing and processing of vehicle light conductors, can solve the problems of light energy loss, low efficiency, and insufficient vision, and achieves the effect of improving input energy and improving use efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

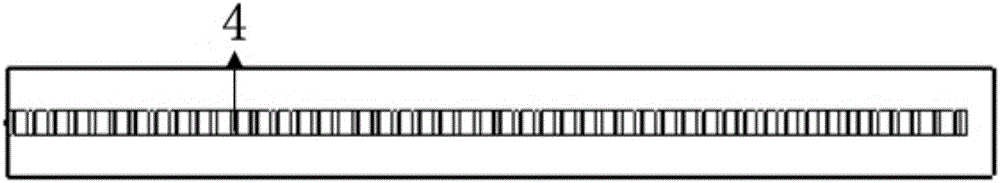

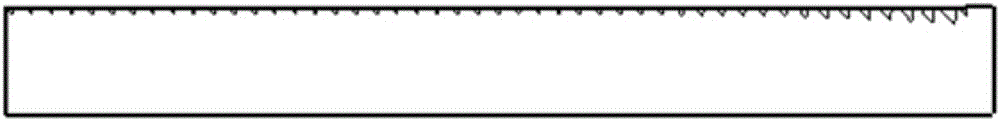

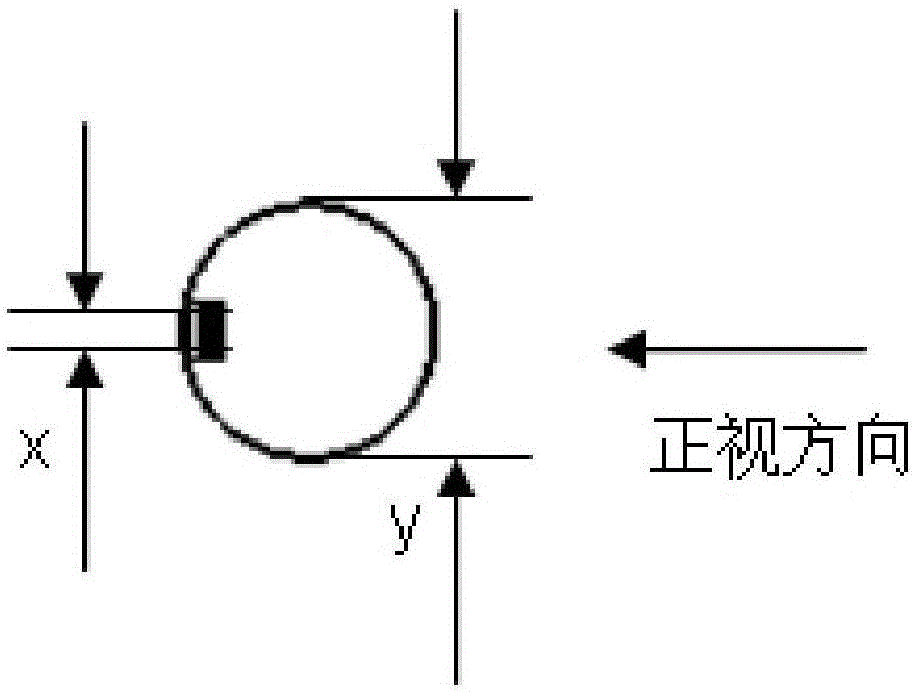

[0035] The invention relates to a spiral light guide tooth for a car lamp. The light guide tooth is arranged on the whole circumference of the strip light guide body, and the light guide tooth covers the periphery of the strip light guide body in a spiral shape. The diameter of the light guide is 5-10mm.

[0036] The distance between the light guide teeth spirally covering the periphery of the bar-shaped light guide body is 0.5-2 mm, and the height of the light guide teeth is 0.3-1 mm.

[0037] In addition, the installation inclination of the light guide teeth covering the periphery of the bar-shaped light guide body in a spiral shape is 15-45 degrees.

[0038] The material of the optical guide tooth is PC or PMMA.

[0039] The angle R of the tips of the light-guiding teeth covering the periphery of the bar-shaped light-guiding body in a spiral shape is 0.04-0.07.

Embodiment 2

[0041] Except for the following differences, others are the same as in Example 1, and a spiral light guide tooth for a car lamp of the present invention is obtained:

[0042] Light-guiding teeth are arranged around the entire circumference of the strip-shaped light-guiding body, and the light-guiding teeth cover the periphery of the strip-shaped light-guiding body in a spiral shape. The diameter of the light guide is 5-10mm.

[0043] The distance between the light guide teeth spirally covering the periphery of the bar-shaped light guide body is 0.5-2 mm, and the height of the light guide teeth is 0.3-1 mm.

[0044] In addition, the installation inclination of the light guide teeth covering the periphery of the bar-shaped light guide body in a spiral shape is 15-45 degrees.

[0045] The angle R of the tips of the light-guiding teeth covering the periphery of the bar-shaped light-guiding body in a spiral shape is 0.04-0.07.

[0046] According to the spiral light guide tooth fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com