Gyratory crusher

A gyratory crusher and crusher technology, applied in grain processing and other directions, to achieve the effect of reducing the net width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

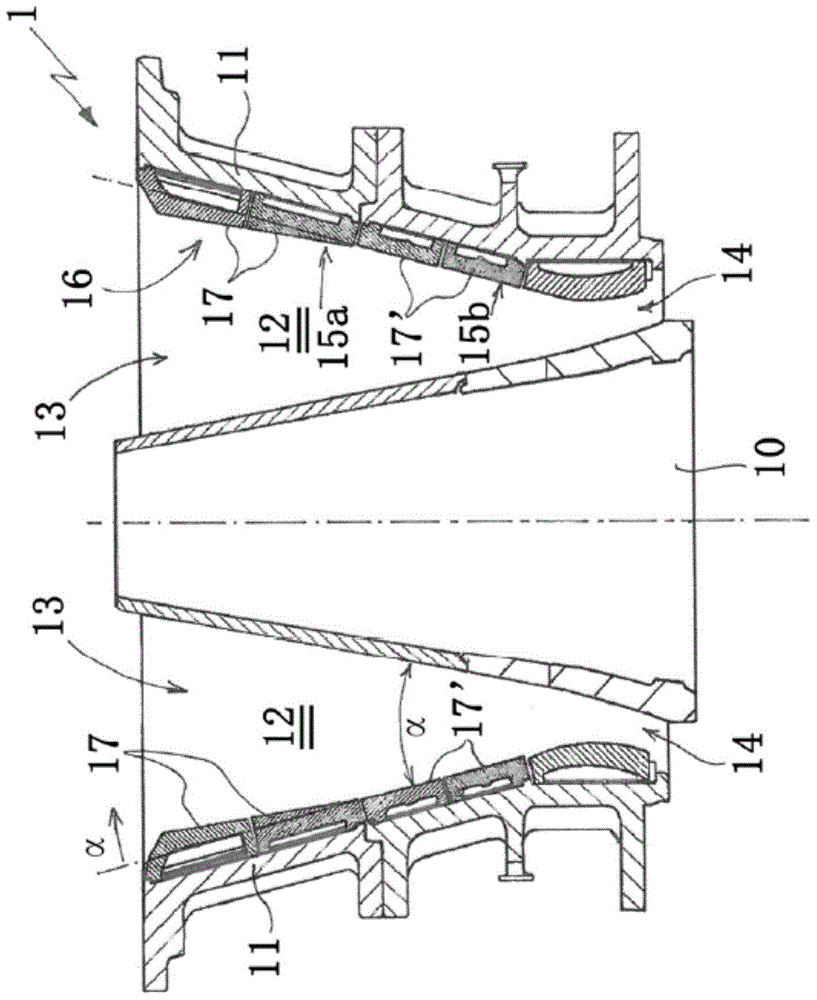

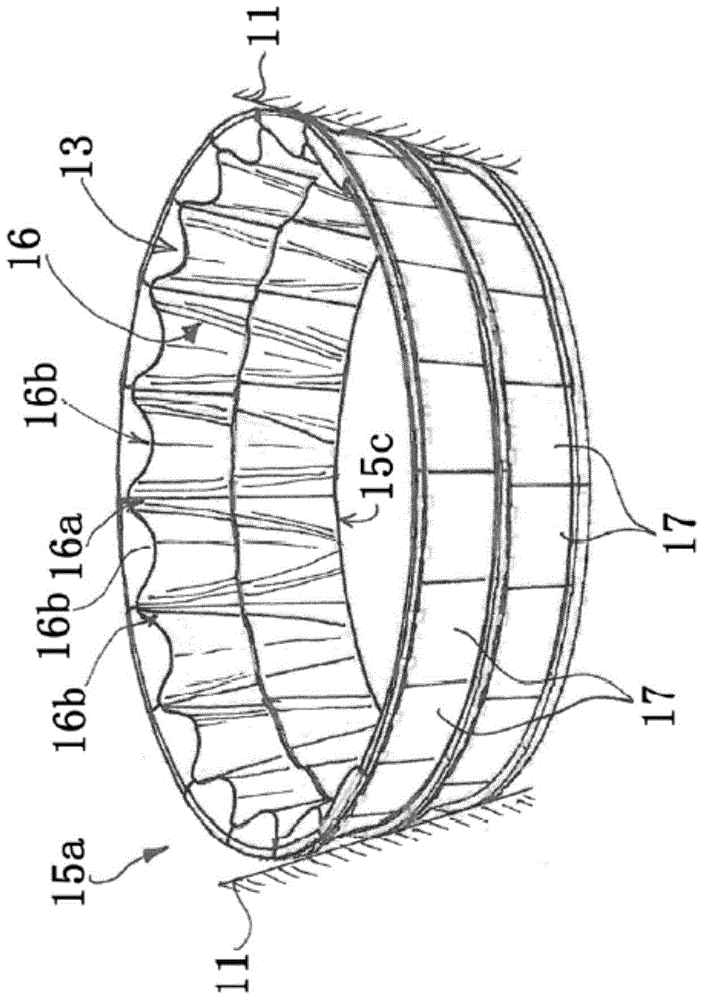

[0019] figure 1 A gyratory crusher 1 with a crushing cone 10 and a crusher housing 11 is shown in a cross-sectional view, wherein the drive, the cone mounting and other parts of the undercarriage of the gyratory crusher 1 are not shown for reasons of clarity part.

[0020] The crusher housing 11 together with the crushing cone 10 forms an encircling crushing space 12 which is open towards the top with respect to the crushing throat 13 at a feed angle α in a radial plane. In the lower region, the crushing cone 10 together with the crusher housing 11 forms an annular crushing gap 14 such that the crushing space 12 tapers downwards into the crushing gap 14 . The crushing cone 10 is arranged in a convoluted rotational movement by means of an eccentric (not shown), so that the crushing gap 14 increases and decreases periodically in a revolving manner.

[0021] If the quarry material is crushed by periodically increasing and decreasing the clear width surrounding the crushing spac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com