Extended room temperature storage of epoxy resins

A technology of epoxy resin and resin, which is applied in the field of curing combination of thermoplastic material toughened epoxy resin, resin and fiber reinforced material, which can solve the problems of prepregs that are difficult to handle and difficult to put into molds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

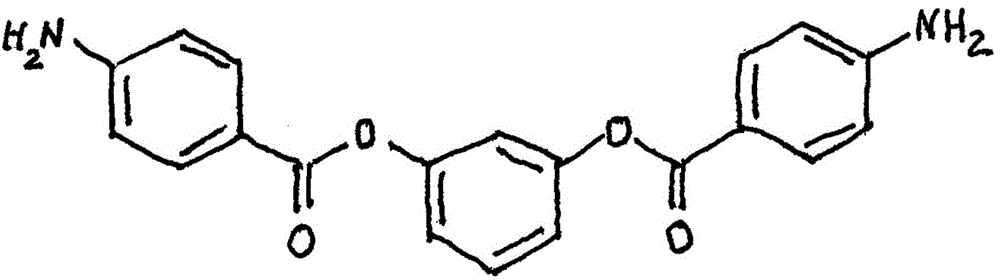

[0055] 3-ABOAB can be synthesized using known chemical procedures for the preparation of norbornanediamine (NBDA), or can be purchased commercially from chemical suppliers such as Mitsui Chemicals America, Inc. under the tradename 13p-BABB.

[0056] The amount of 3-ABOAB included in the uncured resin will depend on the amount and type of epoxy resin present in the uncured resin. The amount of 3-ABOAB should be sufficient to ensure complete cure of the uncured resin while maintaining a constant and relatively low level of heat release from the resin for at least 6 weeks after the resin is made. This amount can be calculated based on the functionality and amount of each epoxy resin in the formulation. The stoichiometric ratio between 3-ABOAB and epoxy resin in the epoxy resin component should be 0.65:1.0 to 1.1:0.8. A preferred stoichiometric ratio between 3-ABOAB and epoxy resin is 0.7:1 to 0.95:1.

[0057] The amount of 3-ABOAB required to provide complete cure at a temperat...

Embodiment 1

[0079] Exemplary uncured resin formulations according to the present invention are described in Table 1 . The uncured resin was prepared by mixing the epoxy resin component with 3-ABOAB as curing agent at room temperature (22°C). The two components are mixed thoroughly to form an uncured resin.

[0080] Table 1

[0081]

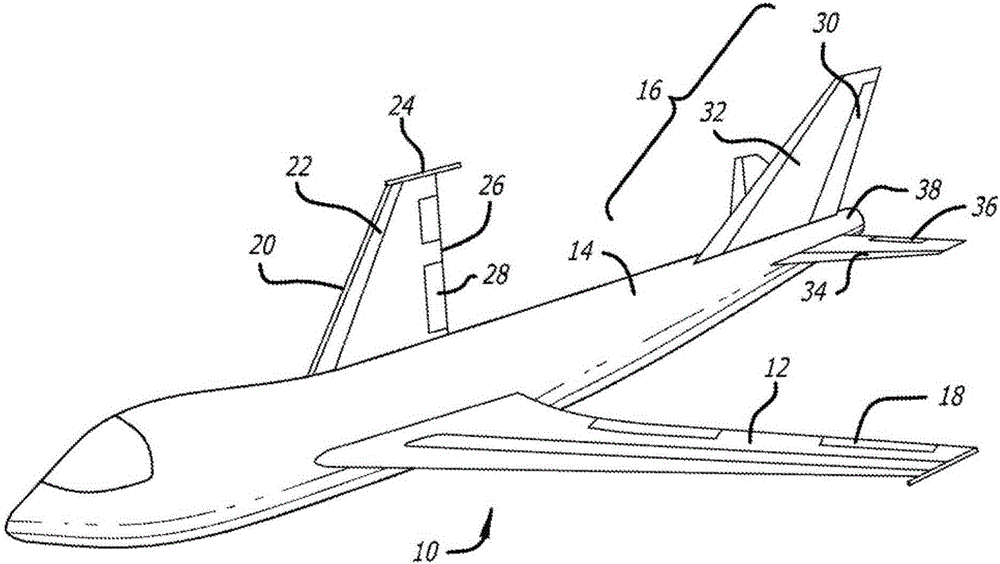

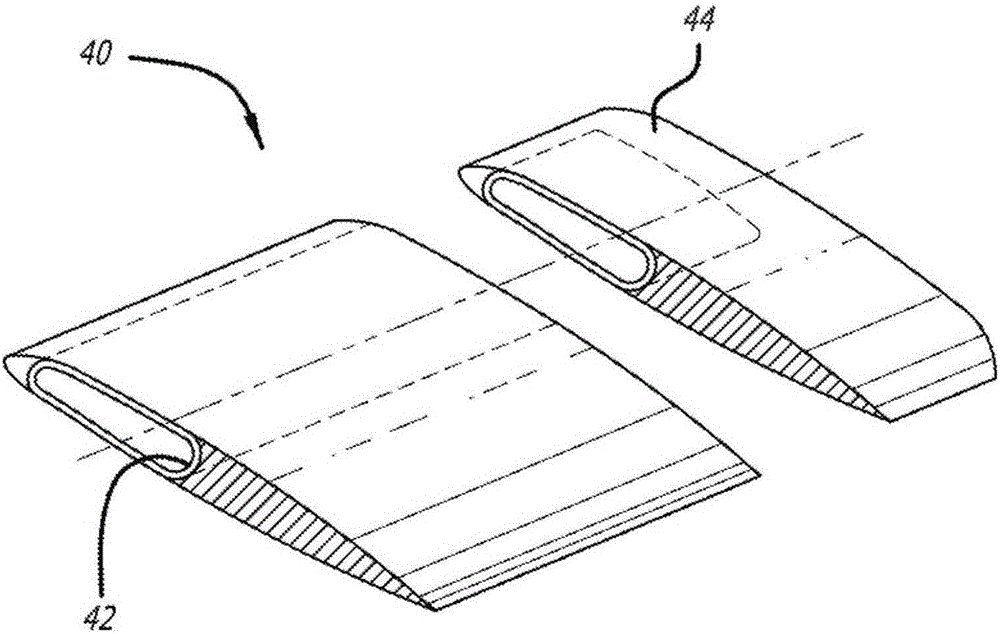

[0082] The viscosity of the uncured resin is suitable for making prepregs. When impregnated into the fiber reinforcement, the resulting prepreg will have tacky properties suitable for forming shaped articles. Exemplary prepregs can be prepared by impregnating one or more layers of unidirectional carbon fibers with the resin formulations of Table 1. Unidirectional carbon fibers were used to make prepregs in which the matrix resin amounted to about 35 wt% of the total uncured prepreg weight, with a fiber areal weight of about 190 grams per square meter (gsm). A variety of prepreg layups can be prepared using standard prepreg manufacturing procedures. Th...

Embodiment 2

[0085] Another exemplary resin formulation according to the present invention is described in Table 2. The uncured resin was prepared by mixing the epoxy resin component with polyethersulfone at room temperature to form a resin blend, and heating the resin blend to 120° C. for 60 minutes to completely dissolve the polyethersulfone. The mixture was cooled to 80°C, the remaining ingredients (polyamide pellets and 3-ABOAB curing agent) were added and mixed thoroughly to form an uncured resin.

[0086] Table 2

[0087]

[0088] The resin formulation was tested using the same DSC test procedure as in Example 1. After 6 weeks, the reaction progress of the uncured resin was essentially 0%. After curing at 177° C. for 2 hours at atmospheric pressure, the reaction progress was greater than 95%, confirming that the resin was fully cured. The viscosity of the uncured resin is suitable for making prepregs. When impregnated into the fiber reinforcement, the resulting prepreg will ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com