Grain harvesting machine and chopping device thereof

A chopping device and harvester technology, applied in the direction of harvesters, agricultural machinery and implements, cutters, etc., can solve problems such as air pollution, difficult to control flames, safety accidents, etc., and achieve the effect of ensuring smooth planting and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Exemplary embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The description of the exemplary embodiments is for the purpose of illustration only, and in no way limits the invention and its application or usage.

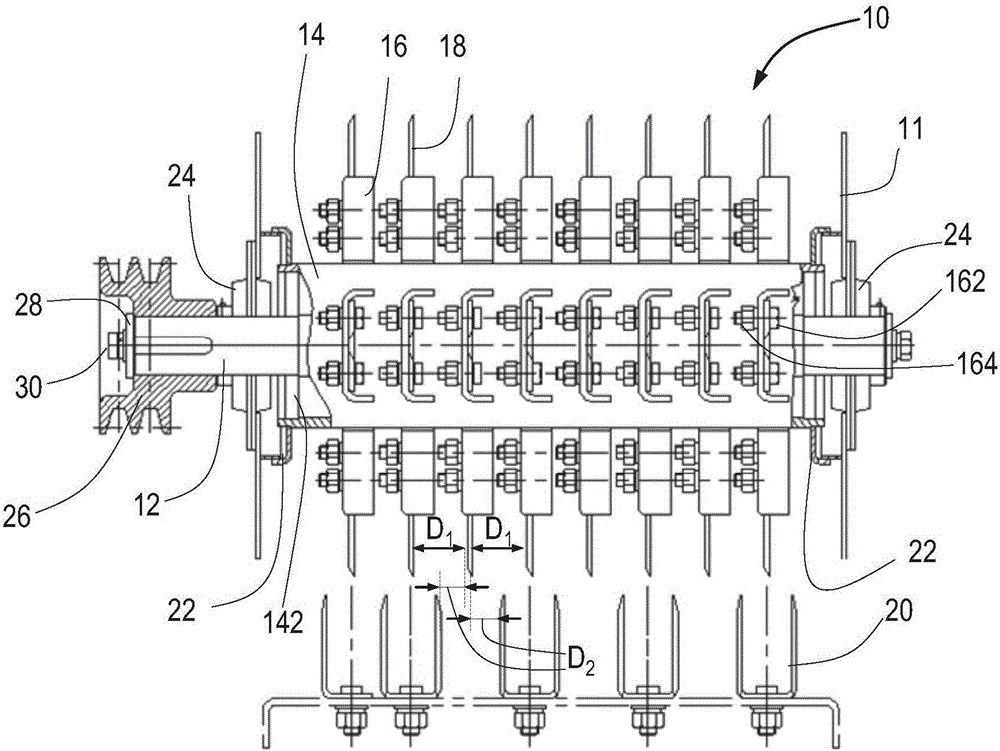

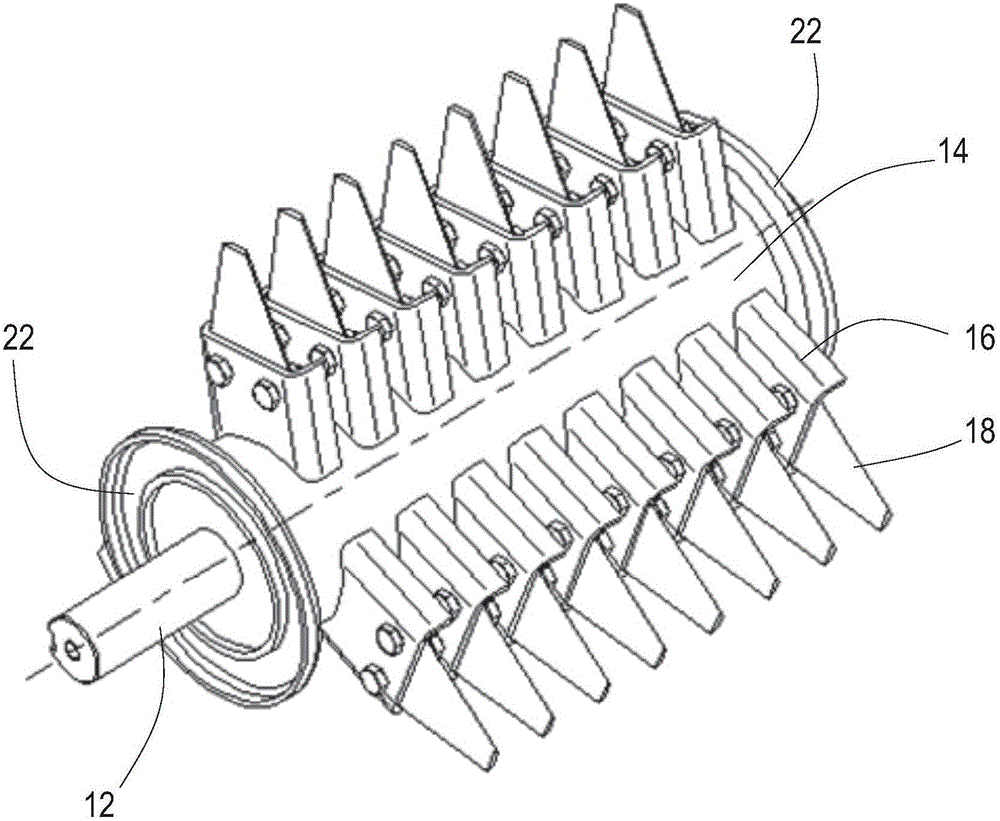

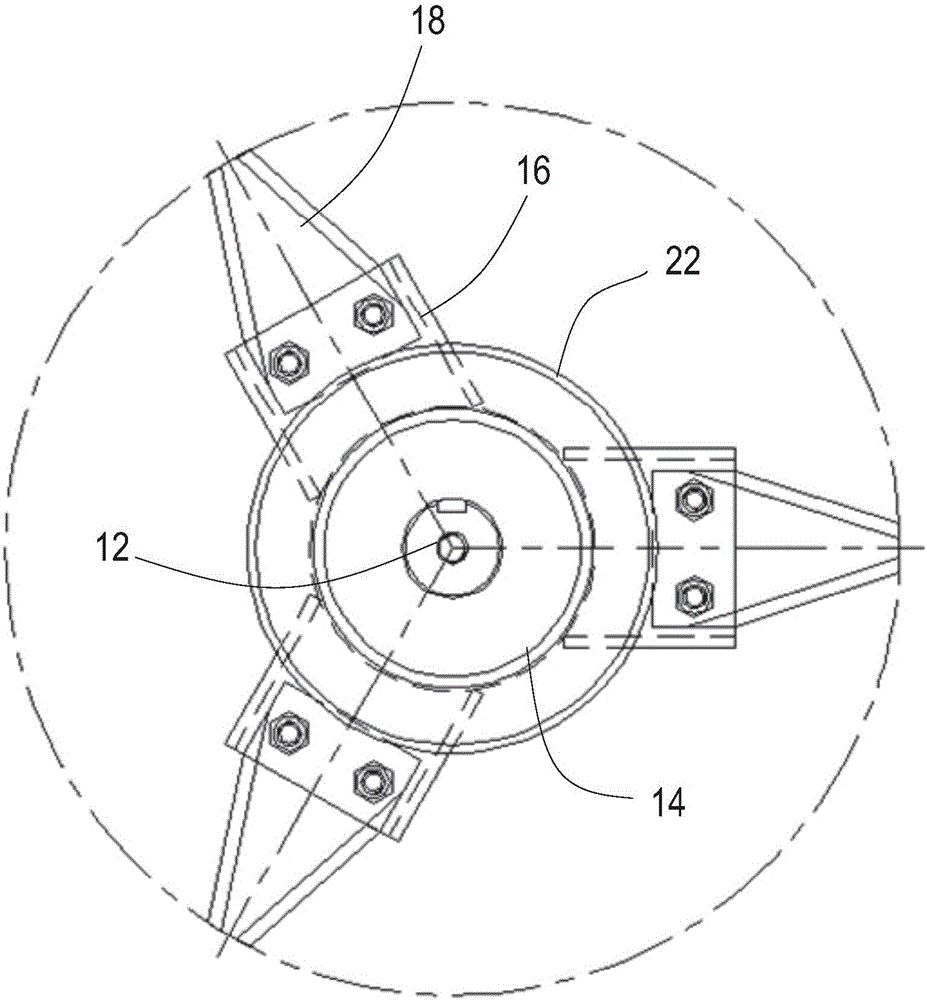

[0022] like figure 1 As shown, a partially cut-away side view of a grain harvester chopping device 10 according to the present invention is shown. Grain harvester chopping device according to the present invention comprises rotating shaft 12, around rotating shaft 12 relatively fixedly arranged drum 14, along the circumferential direction of drum 14 evenly arranged on the outer wall of drum 14 at multiple rows of knife seats 16 , a movable blade 18 disposed in each of the rows of knife seats 16 and a fixed blade 20 disposed corresponding to the movable blade 18 . Here, the rotating shaft 12 can be in the form of a solid shaft, and of course it can also be in the form of a hollow shaft. The dru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com