Anti-leakage method for coffee machine and anti-leakage coffee machine

A coffee machine and anti-drip technology, which is applied in kitchen utensils, household utensils, beverage preparation devices, etc., can solve the problems of endless dripping, poor user experience, and inability to solve the problem of dripping of capsule coffee machines, so as to improve user satisfaction , Solve the effect of dripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

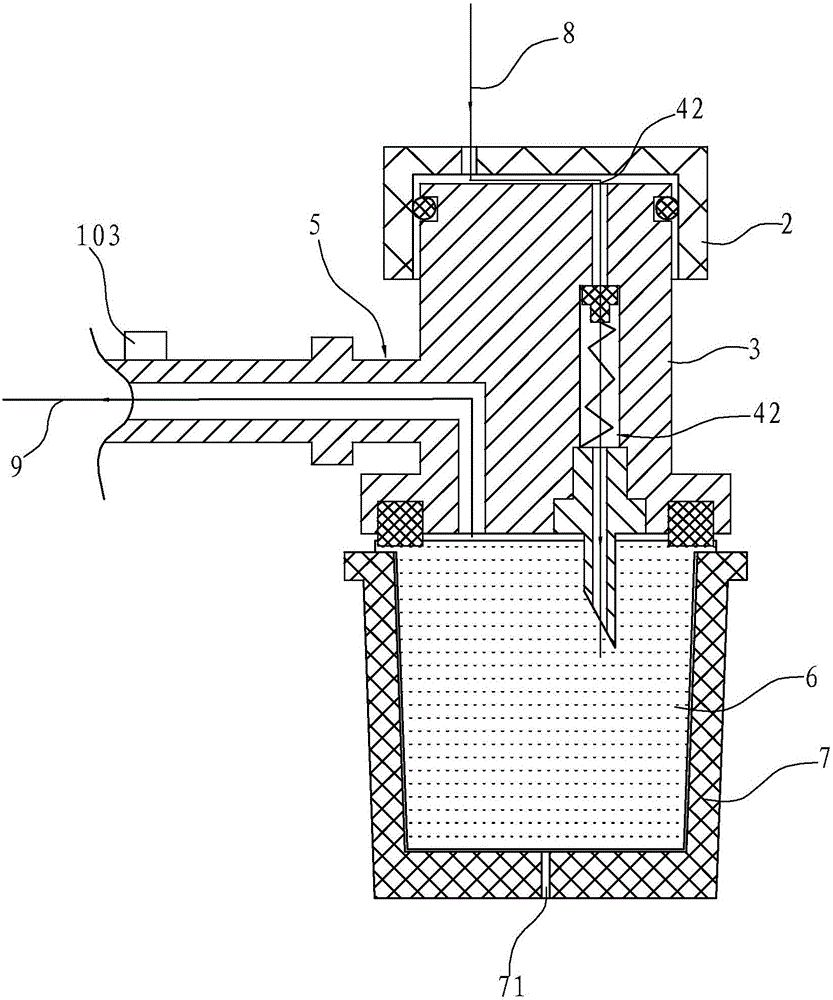

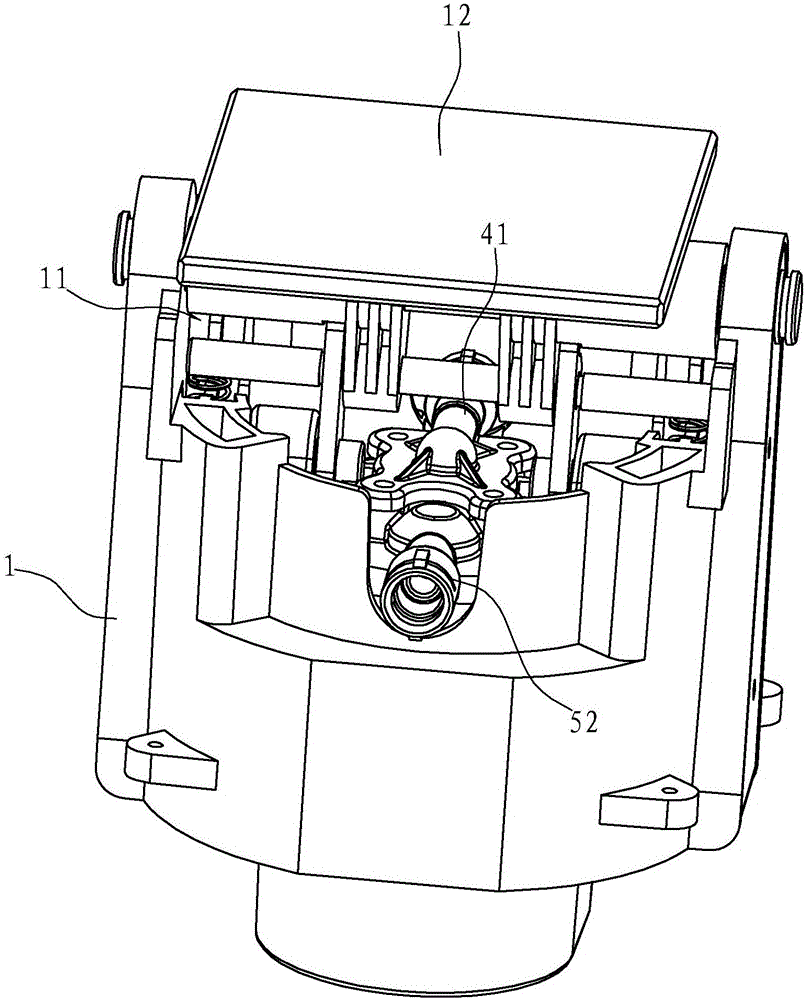

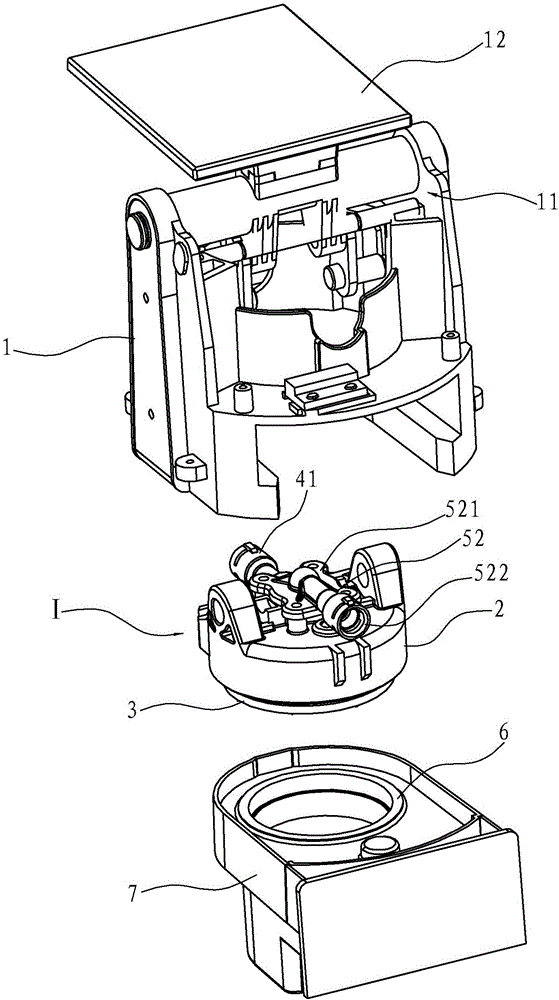

[0025] Such as Figure 2-6 As shown, an anti-drip coffee machine includes a housing 2, a piston 3, a water inlet assembly and a brewing chamber 7 for accommodating a capsule 6. The piston 3 is constrained in the inner cavity of the housing 2 and can be relatively The body 2 slides up and down, and the top of the piston 3 is provided with a limit spring 102 to keep the piston 3 moving downward. The main bracket 1 is arranged outside the housing 2, and the main bracket 1 is provided with a connecting rod structure 11 and a handle 12. , to drive the housing 2 and the piston 3 to move up and down, wherein the connecting rod structure 11 is a conventional structure. The water inlet assembly includes a water inlet channel 41 arranged on the housing 2, a water outlet channel 42 vertically penetrating the piston 3, and a one-way valve assembly arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com