Absorption tower technique for removing ammonia from gas through multi-segment spraying

A process method and absorption tower technology, applied in the field of absorption tower technology, can solve the problems of unreasonable gas distribution, shrinking contact area, large liquid droplets, etc., and achieve the effect of overcoming unreasonable gas distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

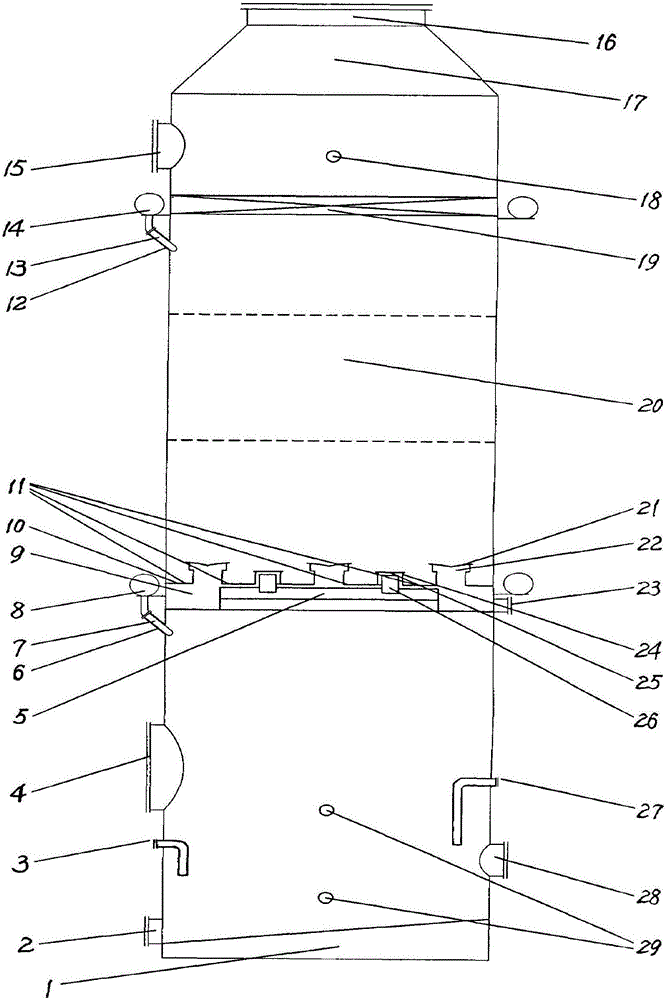

[0017] A multi-stage spraying method for absorbing towers for removing ammonia from gases will be described in detail below in conjunction with the accompanying drawings.

[0018] Referring to the accompanying drawings, the present invention is a multi-stage spray deammonization absorption tower, which consists of a tower body welded from bottom to top by tower base 1, tower body 20 and cone 17, a mist catcher 19, a It consists of an acid supply port 3, an overflow pipe 27, a liquid level gauge, a pressure gauge, a manhole I 28, a manhole II 15 and multi-stage spraying units installed in the tower body 20 at different heights.

[0019] Among them, the upper spraying unit is composed of a spraying device and a liquid breaker plate n 10, and the lowermost spraying unit is composed of a spraying device. The spraying devices are all installed outside the tower, and the nozzles extend into the tower from the outside. The spraying device is composed of a ring pipe I 8, a ring pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com