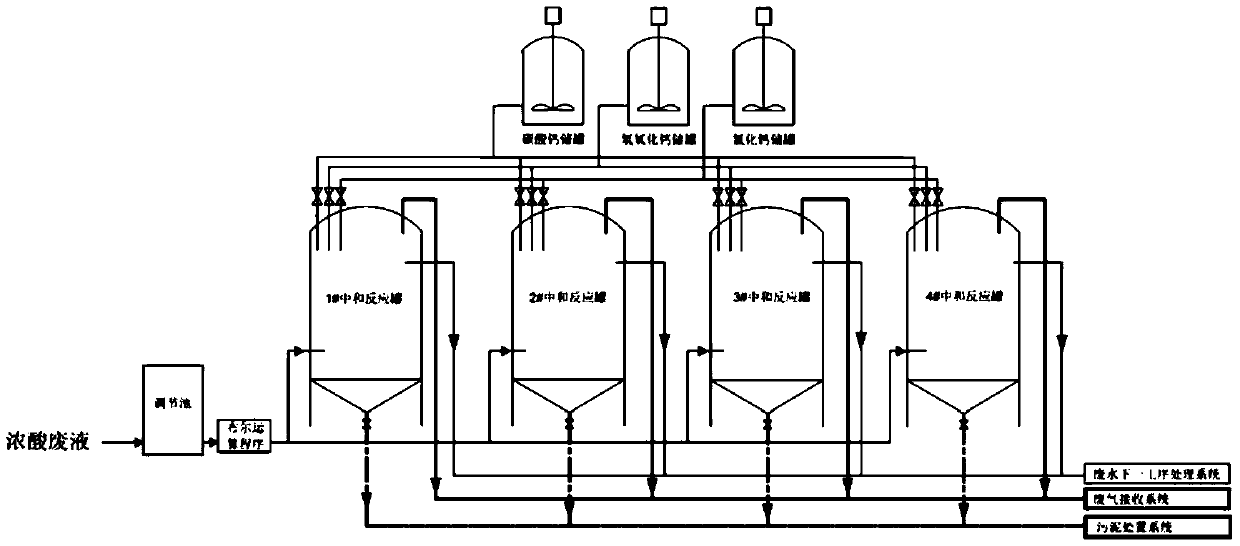

Precise control method for sequencing batch neutralization of concentrated acid wastewater in photovoltaic industry

A control method and batch-sequencing technology, which is applied in water treatment parameter control, chemical instruments and methods, control/manipulation systems, etc., can solve problems such as easily damaged equipment, severe acid-base neutralization reactions, and drug packaging, and achieve saving Operating cost, preventing the pH from rising too high, and preventing incomplete fluoride removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Take 1L of strong acid waste liquid from the photovoltaic industry, the HF content in the waste water is 30%, the fluorine ion concentration is 15g / L, and the HNO 3 The content is 10%, in addition to a small amount of HCl and H 2 SO 4 , after testing, the H in the wastewater + The concentration is about 18mol / L, and the pH is far greater than 1mol / L.

[0044] When the waste water H + When the concentration is greater than 1mol / L, according to the formula M1=60*(C H + -1) Calculate and get CaCO 3 The absolute amount of dosage is 1020g / L, that is, kg / m 3 , during the dosing process with a mass concentration of 40% CaCO 3 Dosing in the form of slurry, stirring during the dosing process, the residence time is 2h, and the pH is 0.5 after the reaction is complete;

[0045] When wastewater 0-pH -0.001) calculation, get CaCO 3 The absolute amount of dosage is 18.91g / L, that is, kg / m 3 , during the dosing process with a mass concentration of 40% CaCO 3 Dosing in the f...

Embodiment 2

[0051] Take 1L of waste acid solution from the photovoltaic industry, the pH of the waste acid solution is 1.5, and the main components of the waste acid are HF and HNO 3 , HCl and H 2 SO 4 etc., wherein the concentration of fluoride ion is 8g / L.

[0052] First, when the waste water is 0-Ph -0.001) calculation, get CaCO 3 The absolute amount of dosing is 1.84g / L, and it is added in the form of a slurry with a mass concentration of 40% during the dosing process, stirred during the dosing process, the residence time is 1h, and the pH is 3.0 after the reaction is complete;

[0053] Then, according to the calculation formula M of 3Ca(OH)2 =45*10 -pH ,M CaCl2 =3*C F- -M1-M2, where M1=0, M2=1.84g / L, after calculation, Ca(OH) 2 Dosing absolute amount is 0.045g / L, CaCl 2 The absolute amount of dosage is 22.16g / L. Ca(OH) 2 Dosing in the form of a slurry with a mass concentration of 40% during the dosing process, CaCl 2 Dosing in the form of a slurry with a mass concentration ...

Embodiment 3

[0055] Take 1L of waste acid solution from the photovoltaic industry, the pH of the waste acid solution is 4, and the main components of the waste acid are HF and HNO 3 , HCl and H 2 SO 4 etc., wherein the concentration of fluoride ion is 0.6g / L.

[0056] According to the calculation formula M of 3Ca(OH)2 =45*10 -pH ,M CaCl2 =3*C F- -M1-M2, calculated, Ca(OH) 2 Dosing absolute amount is 0.005g / L, CaCl 2 The absolute amount of dosage is 1.8g / L. Ca(OH) 2 Dosing in the form of a slurry with a mass concentration of 40% during the dosing process, CaCl 2 Dosing in the form of a slurry with a mass concentration of 50% during the dosing process, stirring during the dosing process, the residence time is 1h, and the pH is above 7 after the reaction is complete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com