Preparation method of low-mercury catalyst

A low-mercury catalyst and catalyst technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of limited mercury chloride content, uneven catalyst quality, uneven distribution of mercury chloride, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

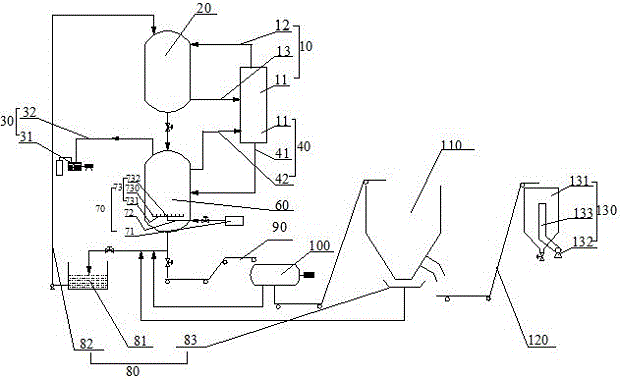

Image

Examples

Embodiment 1

[0048] A preparation method of a low-mercury catalyst, comprising the following steps:

[0049] Deionized water washing: the carbon tetrachloride adsorption rate is greater than or equal to 70%, the specific surface area is greater than or equal to 1200㎡ / g, and the mechanical strength is greater than or equal to 95%, and the activated carbon is first placed in deionized water and rinsed once, during which the water keeps flowing .

[0050] Hydrochloric acid washing: take out the activated carbon from the clean water, place the activated carbon in a hydrochloric acid solution with a concentration of 3.5-5% for rinsing, and keep the hydrochloric acid solution flowing during this period, and repeatedly use the hydrochloric acid solution with a concentration of 3.5-5% to rinse the activated carbon until before rinsing and rinsing Stop washing when the concentration difference of the final hydrochloric acid solution is less than or equal to 5%, then take out the activated carbon fr...

Embodiment 2

[0061] A preparation method of a low-mercury catalyst, comprising the following steps:

[0062] Deionized water washing: the carbon tetrachloride adsorption rate is greater than or equal to 70%, the specific surface area is greater than or equal to 1200㎡ / g, and the mechanical strength is greater than or equal to 95%, and the activated carbon is first placed in deionized water and rinsed once, during which the water keeps flowing .

[0063] Hydrochloric acid washing: take out the activated carbon from the clean water, place the activated carbon in a hydrochloric acid solution with a concentration of 3.5-5% for rinsing, and keep the hydrochloric acid solution flowing during this period, and repeatedly use the hydrochloric acid solution with a concentration of 3.5-5% to rinse the activated carbon until before rinsing and rinsing Stop washing when the concentration difference of the final hydrochloric acid solution is less than or equal to 5%, then take out the activated carbon fr...

Embodiment 3

[0078] A preparation method of a low-mercury catalyst, comprising the following steps:

[0079] Deionized water washing: the carbon tetrachloride adsorption rate is greater than or equal to 70%, the specific surface area is greater than or equal to 1200㎡ / g, and the mechanical strength is greater than or equal to 95%, and the activated carbon is first placed in deionized water and rinsed once, during which the water keeps flowing .

[0080] Hydrochloric acid washing: take out the activated carbon from the clean water, place the activated carbon in a hydrochloric acid solution with a concentration of 3.5-5% for rinsing, and keep the hydrochloric acid solution flowing during this period, and repeatedly use the hydrochloric acid solution with a concentration of 3.5-5% to rinse the activated carbon until before rinsing and rinsing Stop washing when the concentration difference of the final hydrochloric acid solution is less than or equal to 5%, then take out the activated carbon fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com