Micro-fluidic chip and application thereof

A microfluidic chip and microfluidic chip technology, applied in the field of microfluidic control, can solve the problems of long time, low efficiency, high cost, manual configuration, etc., and achieve the effect of simple structure and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

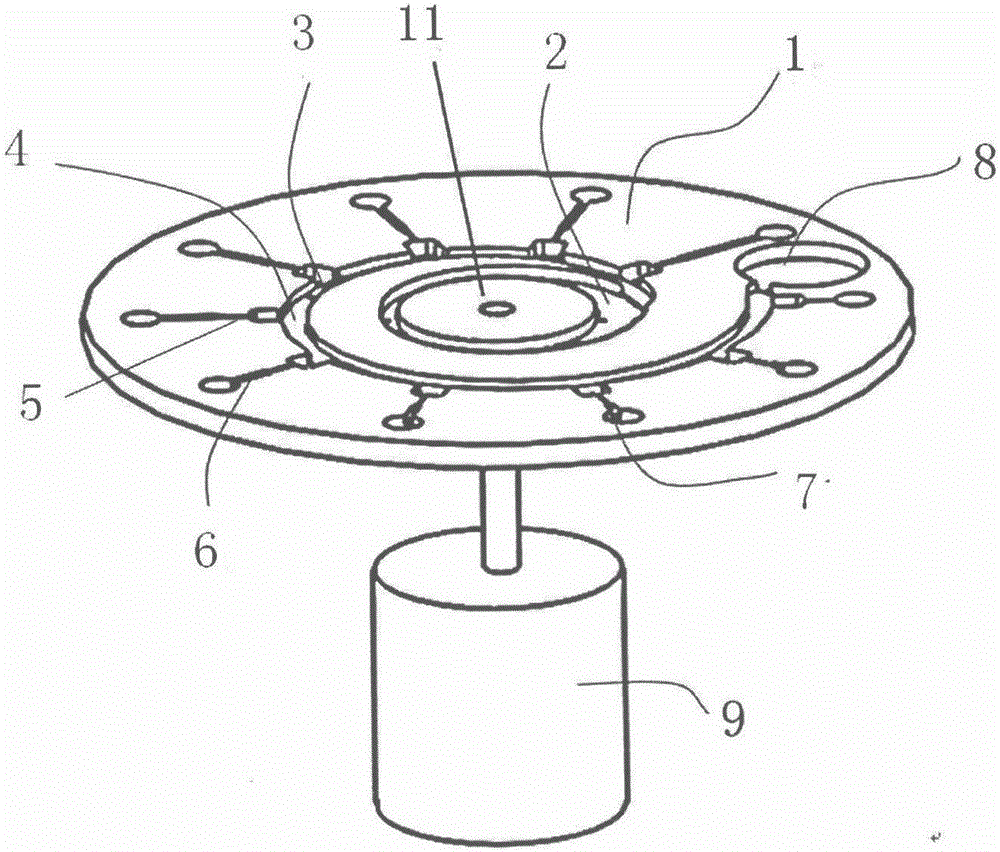

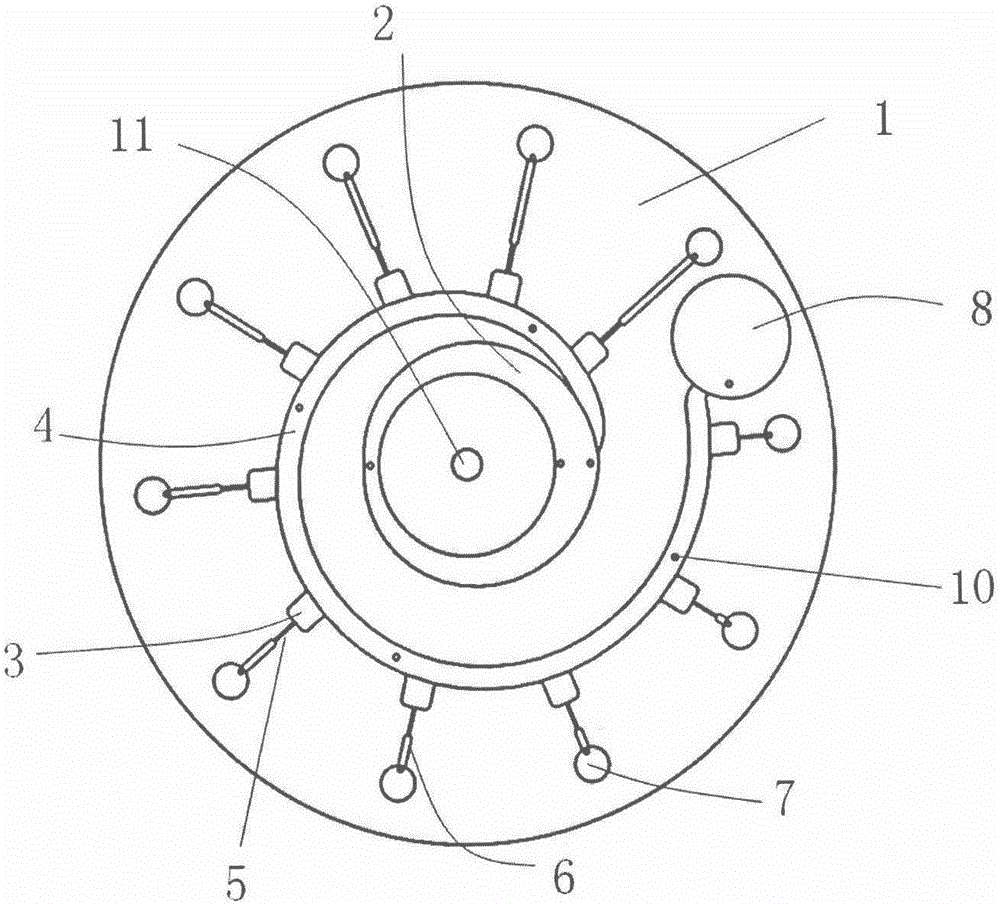

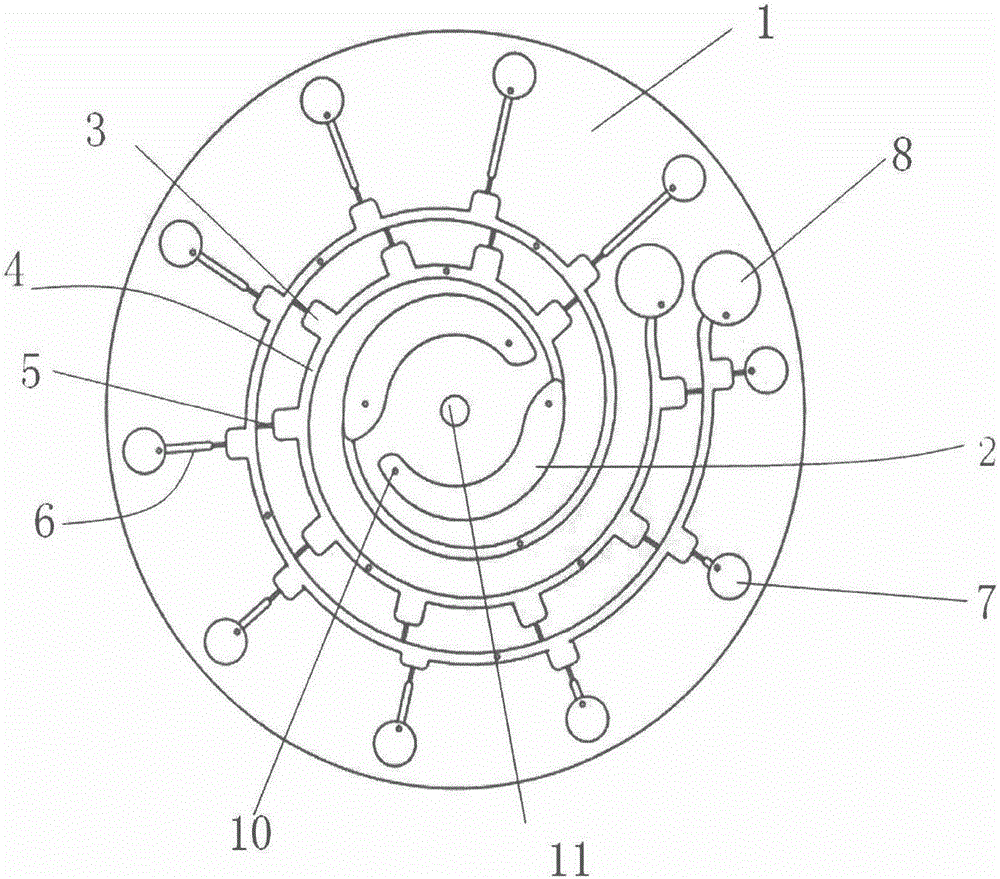

[0029] Below in conjunction with accompanying drawing, technical scheme of the present invention is described further:

[0030] Such as figure 1 , figure 2 As shown, it is a microfluidic chip of the present invention. A spiral channel is provided on the chip body, and corresponding sample chambers, spiral channels, waste liquid chambers, metering chambers, microvalves, microfluidic channels and liquid mixing chambers are provided. The sample chamber is located near the center of the chip, and the waste liquid chamber is located near the edge of the chip. The spiral channel has a proximal end and a distal end, the proximal end communicates with the sample chamber, and the distal end communicates with the waste liquid pool. The metering chambers are distributed on the outside of the spiral channel along the spiral channel and communicate with the spiral channel. A microvalve is connected to the outside of each metering chamber; the microfluidic channels respectively open to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com