Finished brown corundum product screening equipment

A finished product and sub-sieving technology, which is applied in the direction of screening, solid separation, grille, etc., can solve the problems of insufficient preparation for screening, waste of enterprises, mixed corundum, etc., and achieve the effects of simple structure, increased efficiency, and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

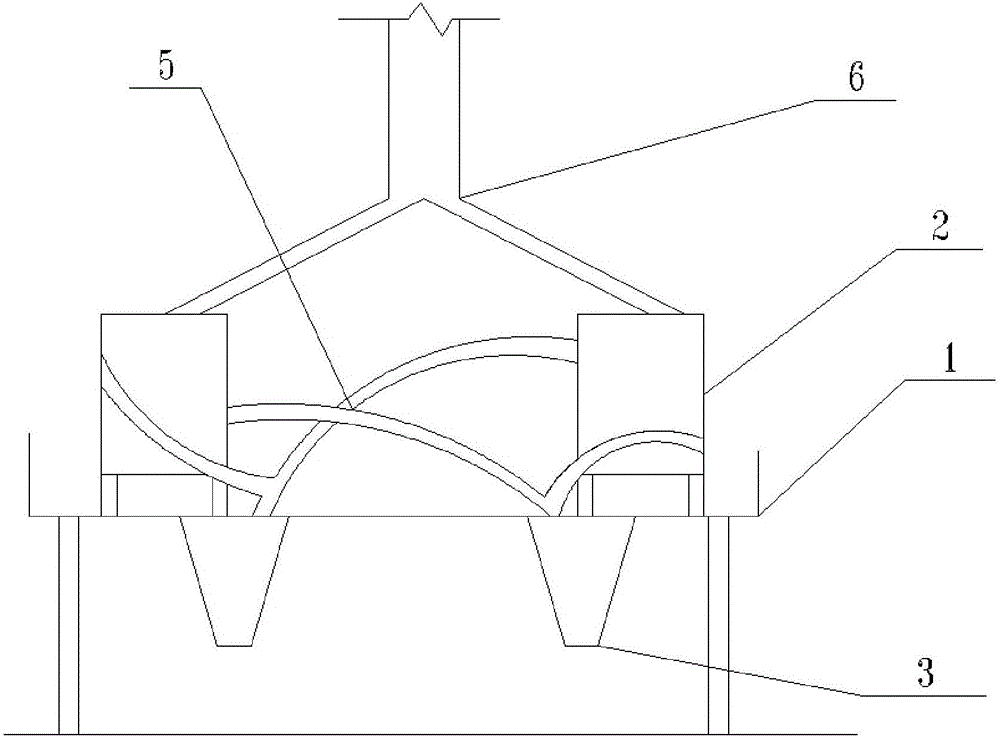

[0012] Embodiment of the present invention: a kind of screening equipment for brown corundum finished products, including an operation table 1 arranged on the ground, characterized in that: at least two vibrating screeners 2 are arranged on the operation table 1, and on the table of the operation table 1 At least two collection funnels 3 are provided, and the discharge port 4 on the vibrating classifier 2 is communicated with the corresponding collecting funnel 3 through a pipeline 5, and a feeding pipe 6 is provided at the inlet end of the vibrating classifier 2.

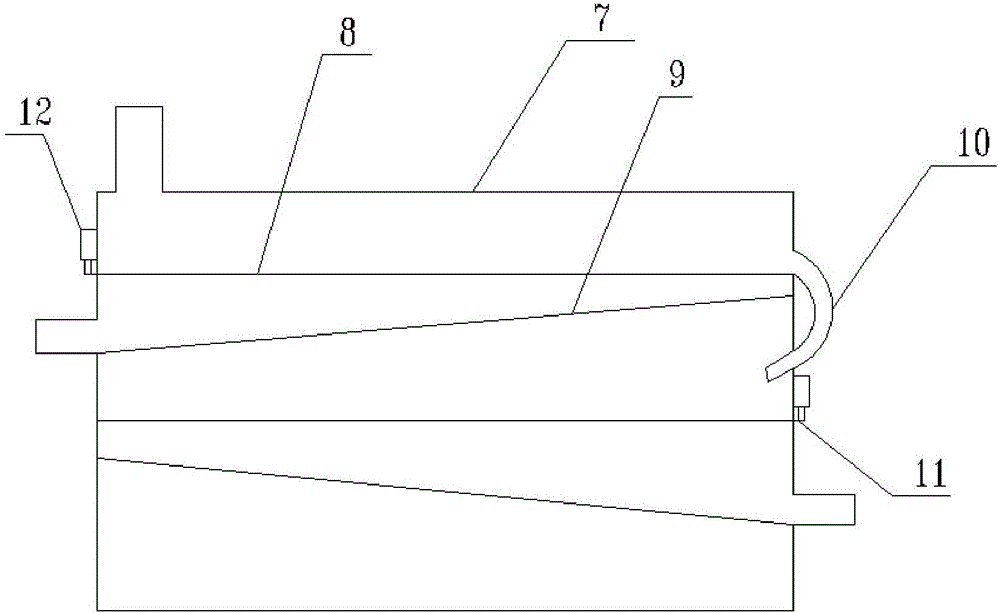

[0013] Wherein the vibrating splitter 2 comprises a vibrating splitter frame body 7, at least 2 layers of screens 8 with different sieve sizes are set at the vibrating splitter frame body 7, adjacent screens 8 are overlapped, Below this is the corresponding receiving frame 9, which is placed obliquely and the corresponding discharge port 4 is set at the tail end of the receiving frame 9, and the discharge end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com