A crystallizer structure and cooling method inside the crystallizer

A cooling method and crystallizer technology, applied in the field of iron and steel metallurgy, can solve the problems of slow cooling molten steel, poor adaptability, and high maintenance costs, and achieve the effects of reducing molten steel superheat, simple and reasonable structure, and reducing temperature gradients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

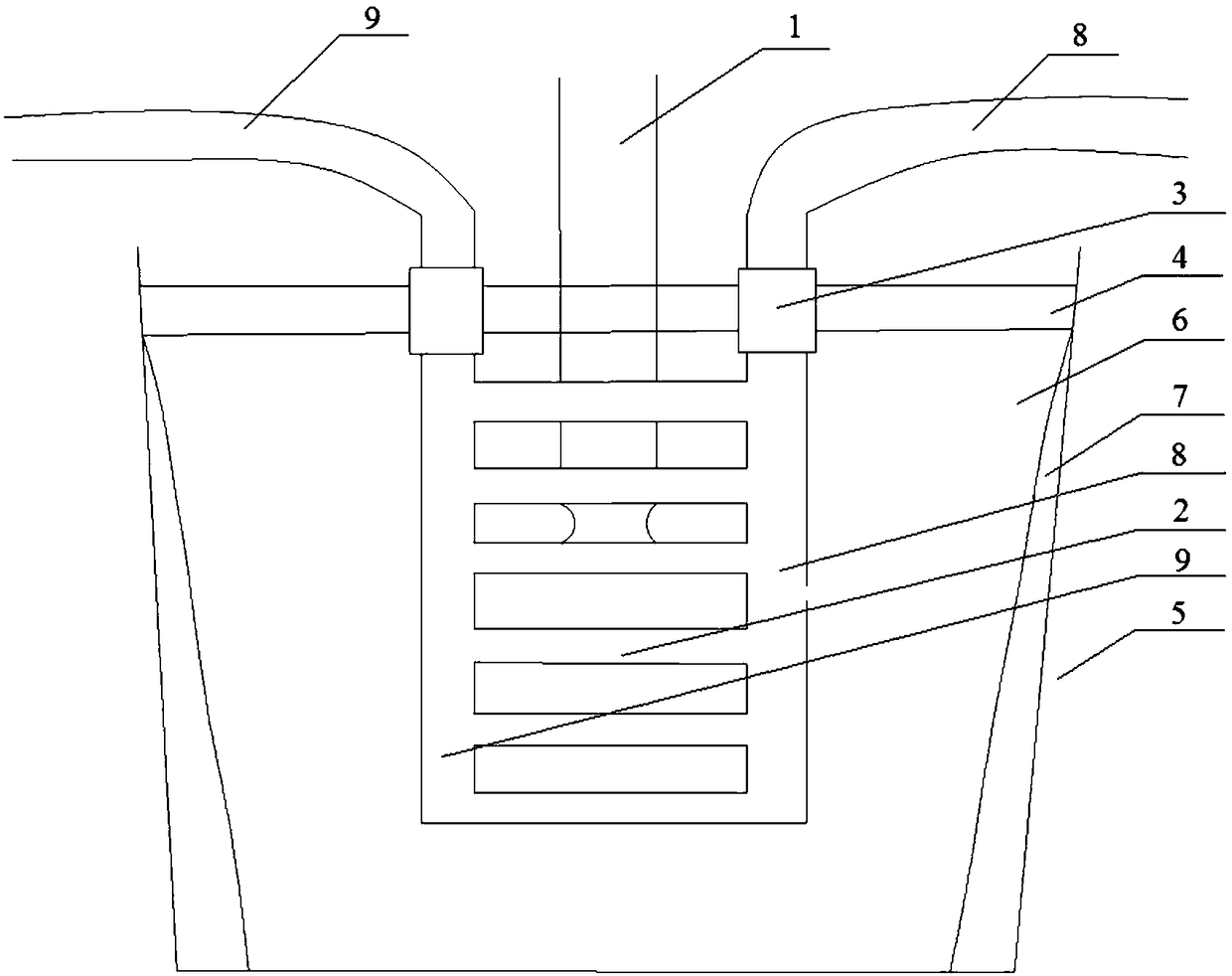

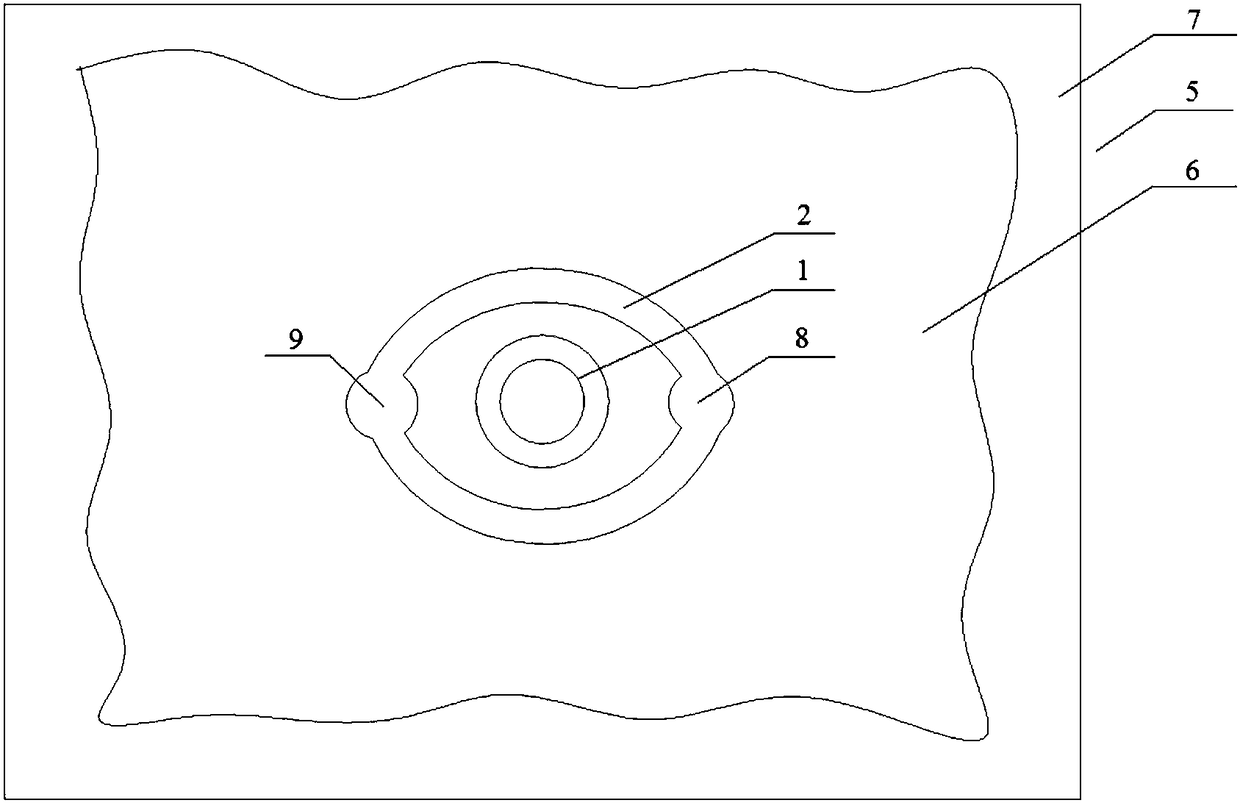

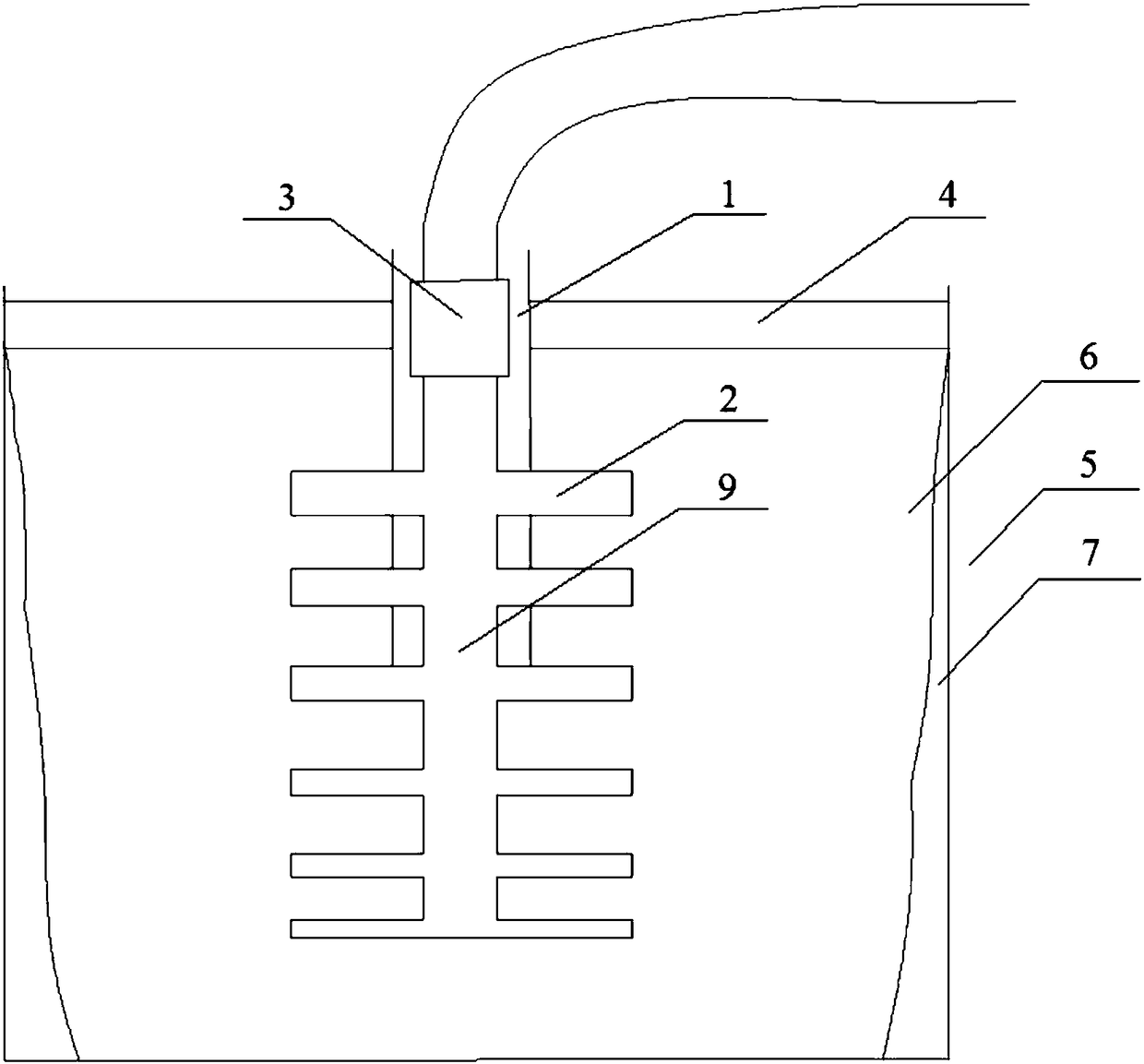

[0044] Embodiment 1: A cooling device built into a slab crystallizer.

[0045] A cooling device built into the slab crystallizer, such as Figure 1-3 As shown, the billet size is 160mm×1260mm, and 10 elliptical annular pipes are arranged in the crystallizer 5 to form a cooling device. The inner diameter of the first circular pipe at the upper part of the cooling device is 0.8mm, and the inner diameter of the last circular pipe at the lower part is 0.4mm. , the inner diameter of the circular tube decreases from top to bottom, the wall thickness of the circular tube is 5mm, and the water flow rate in the circular tube is 0.4m / s. The parts where the water inlet pipe 8 and outlet pipe 9 of the cooling device are in contact with the mold slag 4 need to be wrapped with heat insulating components 3 In order to avoid the cooling effect of this device on the mold powder 4, the pipe material is steel, and after the cooling water system is connected from the outside of the crystallizer 5...

Embodiment 2

[0046] Embodiment 2: A cooling device built into a billet crystallizer.

[0047] A cooling device built into the billet crystallizer, such as Figure 1-3 As shown, the size of the billet is 220mm×220mm. Three circular pipes are arranged in the crystallizer 5 to form a cooling device. The inner diameter of the first circular pipe on the upper part of the cooling device is 0.9mm, and the inner diameter of the last circular pipe on the lower part is 0.5mm. , the inner diameter of the circular tube decreases from top to bottom, the wall thickness of the circular tube is 6mm, and the water flow rate in the circular tube is 0.5m / s. In order to avoid the cooling effect of this device on the mold powder 4, the material of the pipeline is steel, and after being connected to the cooling water system from the outside, the water circulates in the water inlet pipe 8, the intermediate connecting pipe 2, and the water outlet pipe 9, so as to reduce the The effect of the superheat of molten ...

Embodiment 3

[0048] Embodiment 3: A cooling device built into the slab crystallizer.

[0049] A cooling device built into the slab crystallizer, such as Figure 1-3 As shown, the size of the billet is 300mm×1800mm. Six circular pipes are arranged in the crystallizer 5 to form a cooling device. The inner diameter of the first round pipe at the upper part of the cooling pipe group is 1.5mm, and the inner diameter of the last round pipe at the lower part is 1mm. , the inner diameter of the round tube decreases from top to bottom, the wall thickness of the round tube is 8mm, and the water flow rate in the round tube is 0.8m / s. In order to avoid the cooling effect of this device on the mold powder 4, the material of the pipeline is steel, and after being connected to the cooling water system from the outside, the water circulates in the water inlet pipe 8, the intermediate connecting pipe 2, and the water outlet pipe 9, so as to reduce the The effect of the superheat of molten steel. During th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com