Bottom-up powder feeding system

A powder feeding and powder storage technology, which is applied in the field of downlink powder feeding system, can solve the problems of low work efficiency and achieve the effects of convenient upgrading, improved forming efficiency and good rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

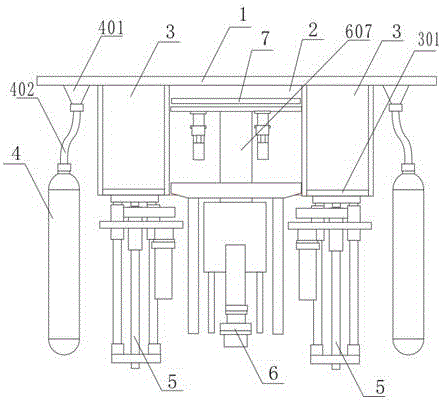

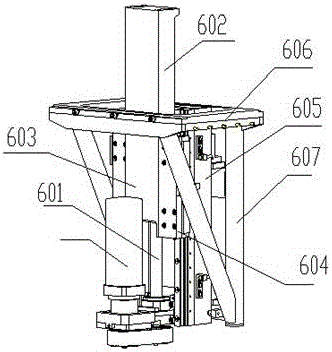

[0031] Embodiment 1: see Figure 1 to Figure 5 , a downward powder feeding system, including a base 1, a forming chamber 2 is provided in the middle of the base 1, a powder feeding chamber 3 is respectively arranged on both sides of the forming chamber 2, and the side of the powder feeding chamber 3 away from the layer forming chamber 2 is respectively There is a powder storage bottle 4; the forming chamber 2, the powder feeding chamber 3, and the powder storage bottle 4 are arranged side by side and closely arranged, and the base 1 is provided with a powder spreading device that circulates powder between the two powder storage bottles 4;

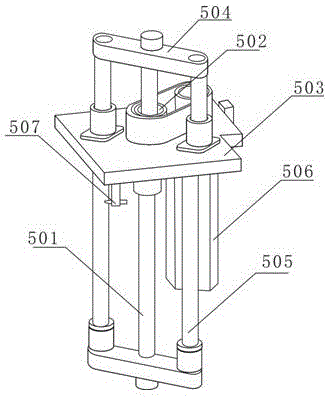

[0032] Both the upper ends of the powder feeding bin 3 and the forming bin 2 are open and flush, the inner bottom of the powder feeding bin 3 is provided with a movable bottom plate, and the bottom of the powder feeding bin 3 is provided with a double guide column linear motion unit 5 that drives the movable bottom plate to move up and down....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com