A method for surfacing welding of flanges of gasifier equipment

A technology of strip surfacing and gasification furnace, which is applied in welding equipment, arc welding equipment, metal processing equipment, etc., can solve problems such as heavy workload, prone to defects, and difficult quality assurance of electrode arc welding, and achieve improved surfacing Welding efficiency, ensure the quality of surfacing welding and the effect of appearance molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A surfacing welding method for flange strips of gasification furnace equipment, comprising the following steps: (1) first surfacing the sealing surface of the flange.

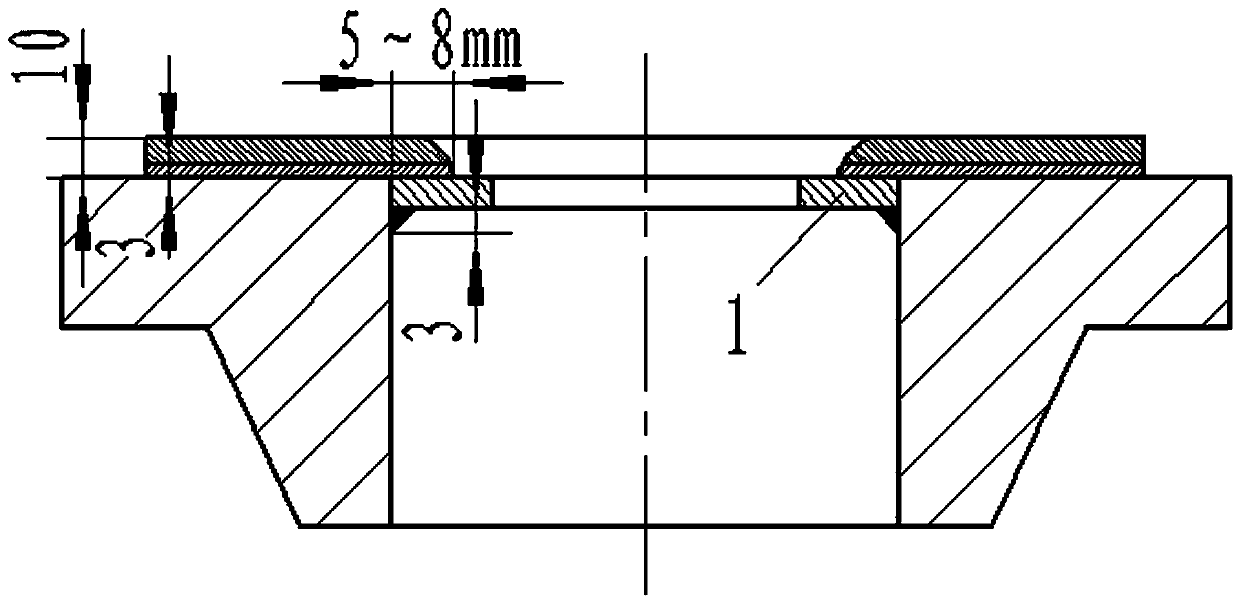

[0019] ① if figure 1 The retaining ring 1 is divided into petals and fixed by spot welding (welding 20 every 200) on the inner wall of the flange. It is required that the upper surface of the retaining ring 1 is flush with the sealing surface of the flange.

[0020] ② After the retaining ring 1 is fixed, the sealing surface of the flange with surfacing welding is adopted, and the transition layer is surfacing until it overlaps with the retaining ring by about 5-8 mm; after the surface layer is surfacing, ensure that the surfacing thickness is ≥ 10 mm.

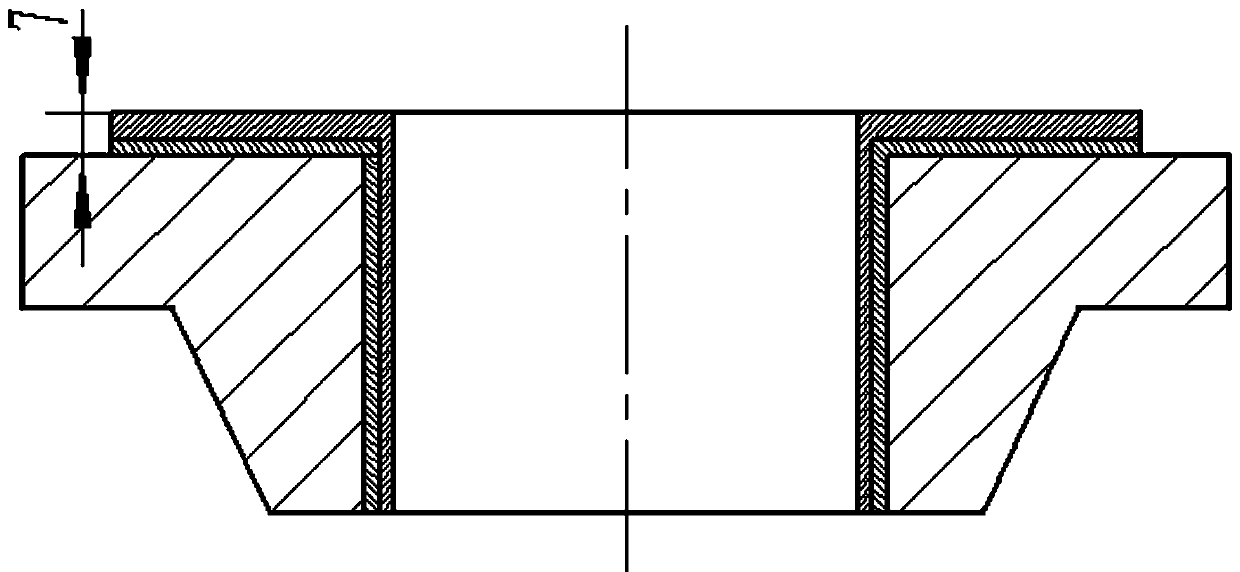

[0021] ③ After the surfacing is completed, remove the retaining ring, and use a grinder to grind the protruding part to a smooth transition with the inner wall of the flange.

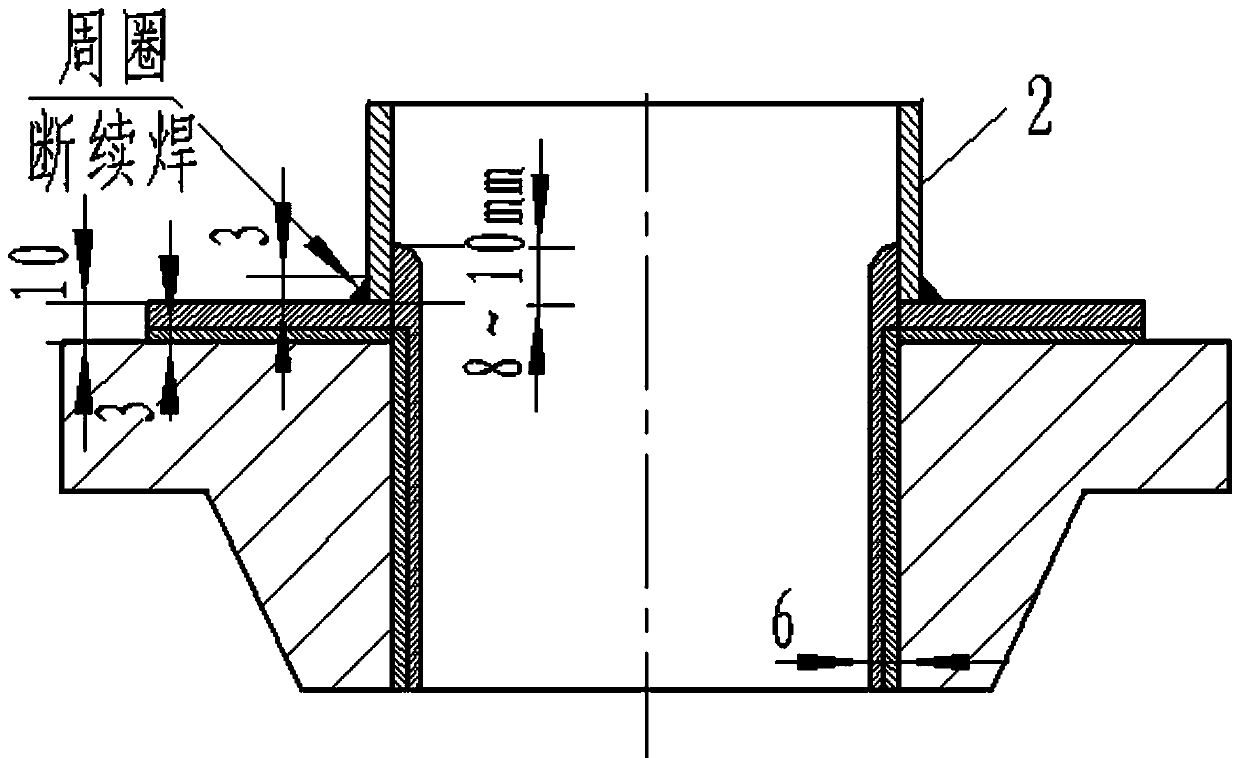

[0022] (2) The inner surface of the surfacing flange.

[0023] ① if figure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com