A Precision Forming Process for Large-Sized Flat Parts with One-Side Complexity

A precision forming and large-size technology, applied in the field of forging and forming, can solve the problems of incomplete filling of complex features, high demand for forming equipment, unstable product quality, etc., and achieve the effect of simple shaping method, simple manufacturing process and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

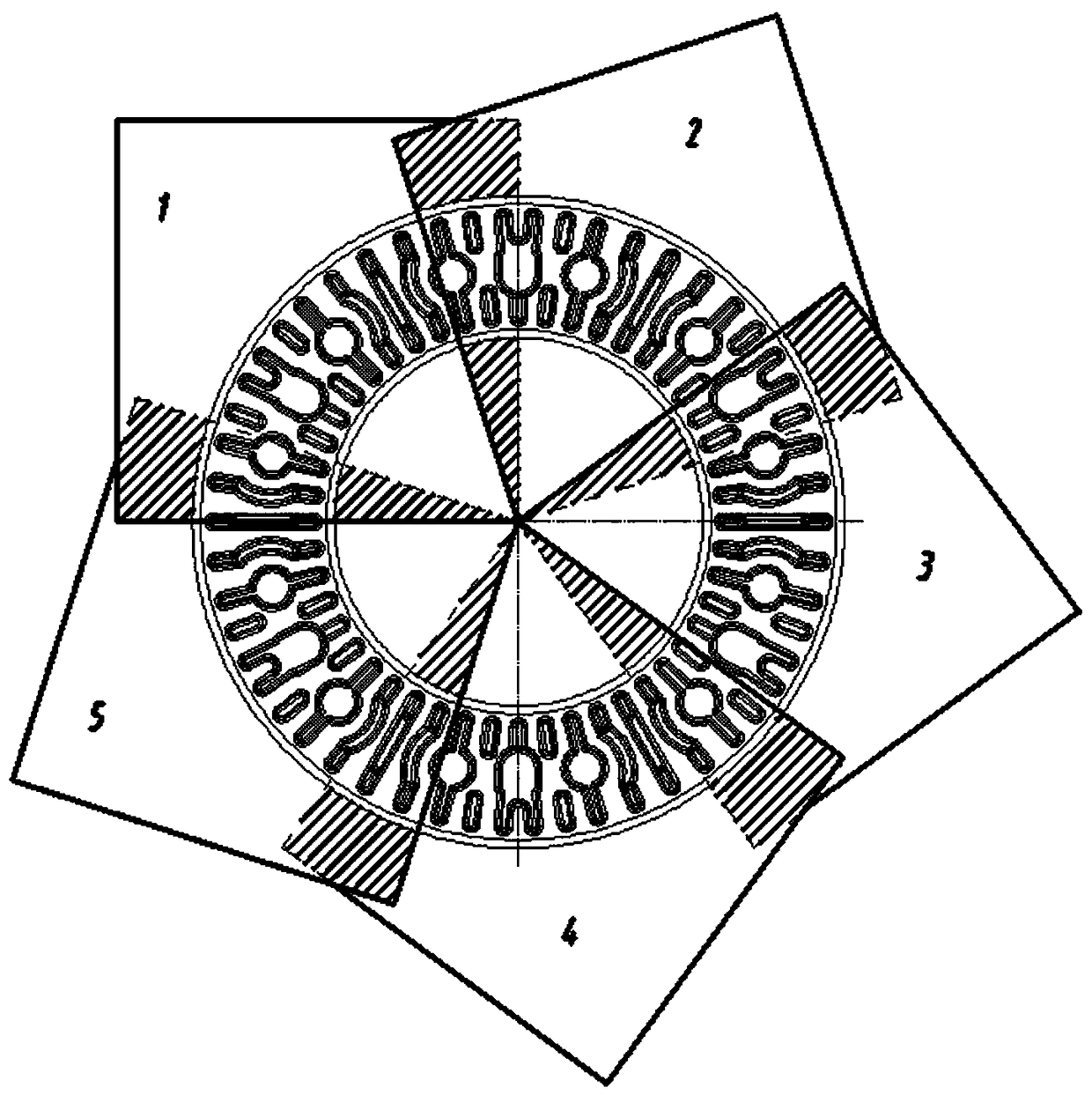

[0052]A typical single-sided complex large-size flat part of the present invention—a high-speed train brake disc part has a large number of evenly distributed heat dissipation ribs on its upper surface and a flat lower surface. Limited by force, it is most difficult to fill the heat dissipation ribs, which affects the product quality. In order to solve this technical problem, the method of die forging and shaping according to the present invention is adopted. The specific process is as follows:

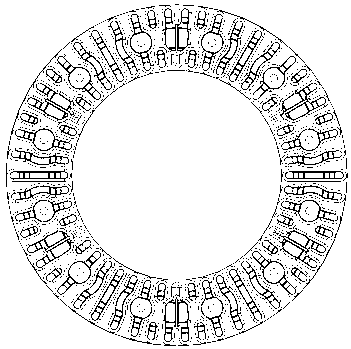

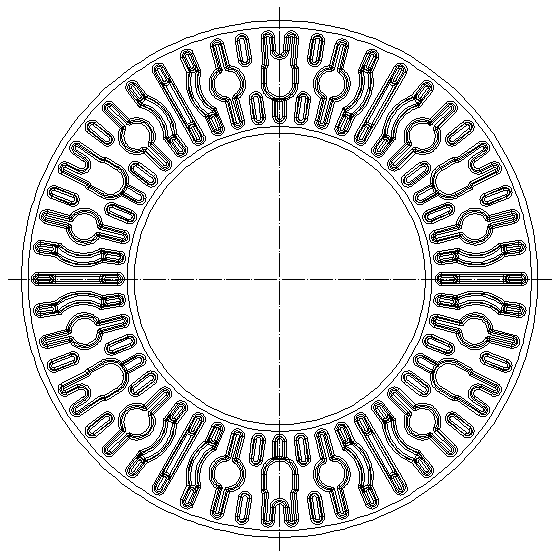

[0053] 1. according to figure 1 Design the forging drawing according to the part drawing shown, and the forging drawing obtained from the design is as follows figure 2 shown;

[0054] 2. According to the forging drawing, a round steel billet with a diameter of 200mm and a height of 440mm was obtained by sawing;

[0055] 3. Use an induction heating furnace to heat the round bar material obtained by blanking to 1180°C;

[0056] 4. Use an electro-hydraulic hammer to upset the hea...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap