Intermittent indexing mechanism for press-assembling of inner ring of knuckle bearing

A joint bearing and indexing mechanism technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of complex structure and low manufacturing cost, and achieve the effect of low manufacturing cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

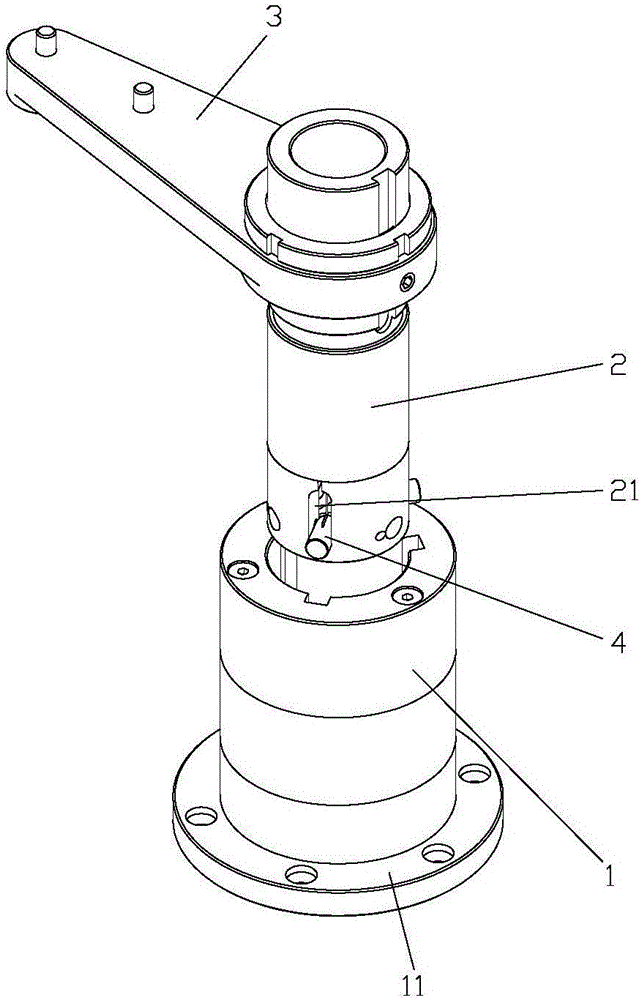

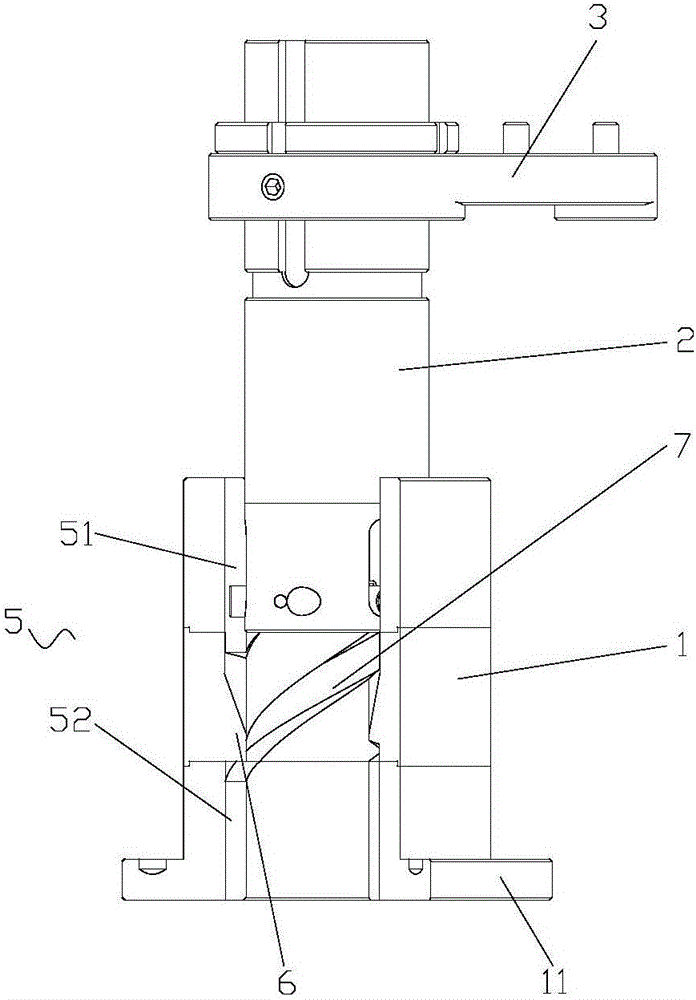

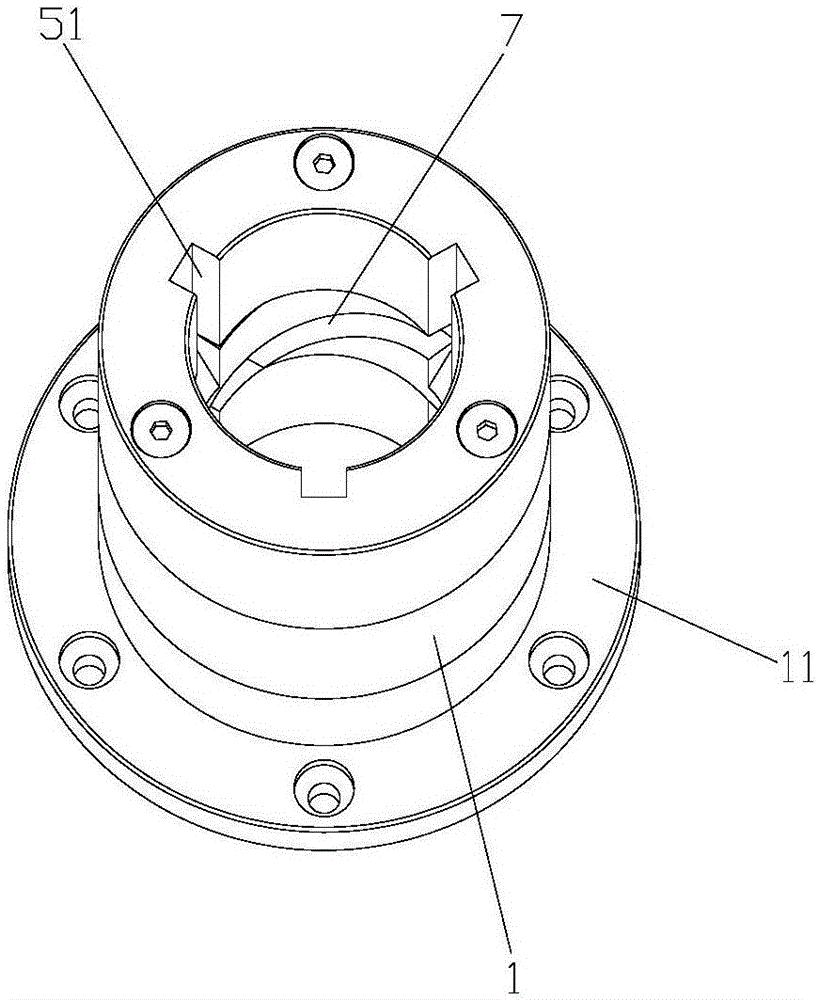

[0014] Such as Figure 1-3 As shown in one of them, the present invention includes a rotary sleeve 1, a drive shaft 2 and a cross arm 3, the bottom of the rotary sleeve 1 is fixedly connected with the turntable, one end of the cross arm 3 is fixedly connected with the top of the drive shaft 2, and the other end of the cross arm 3 It is connected with the punch of the punching machine; the lower part of the drive shaft 2 is provided with more than two relief grooves 21 at equal intervals along the circumferential direction, and each relief groove 21 is connected with a pawl 4 through an elastic member, and the pawl 4 is cylindrical , when the pawl 4 is squeezed, it retreats into the corresponding relief groove 21; the hole wall of the inner hole of the rotary sleeve 1 is provided with chutes 5 with the same number as the 4 pawls at equal intervals along the circumferential direction, and the chute 5 Slidingly matched with the ratchet 4, the chute 5 includes an upper straight gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com