Multi-angle two-dimensional ultrasonic vibration assisted nanofluid minimal lubrication grinding device

A nano-fluid and vibration device technology, applied in the field of grinding, can solve the problems of excessive cutting edge damage, difficult cooling of the workpiece, thermal damage of the workpiece, etc., to avoid machining errors, improve the surface quality of the workpiece, and save time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064]The present invention will be further described below in conjunction with the specific embodiments of the accompanying drawings:

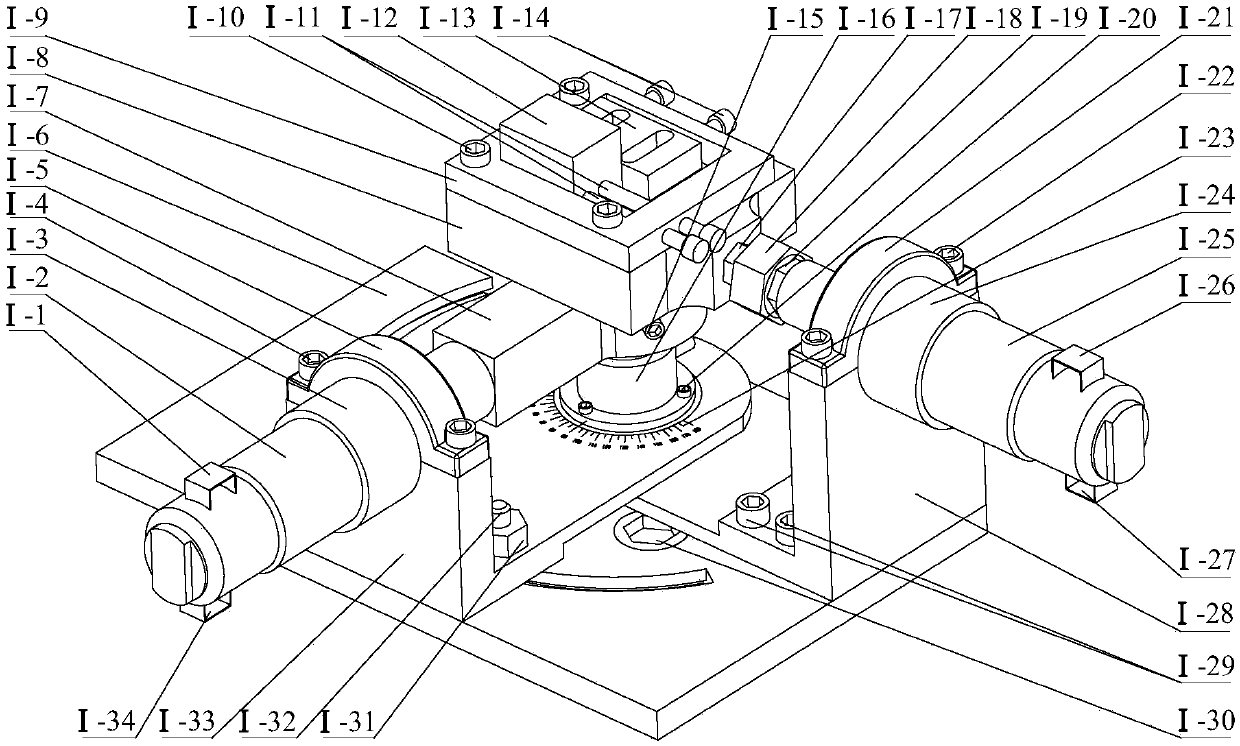

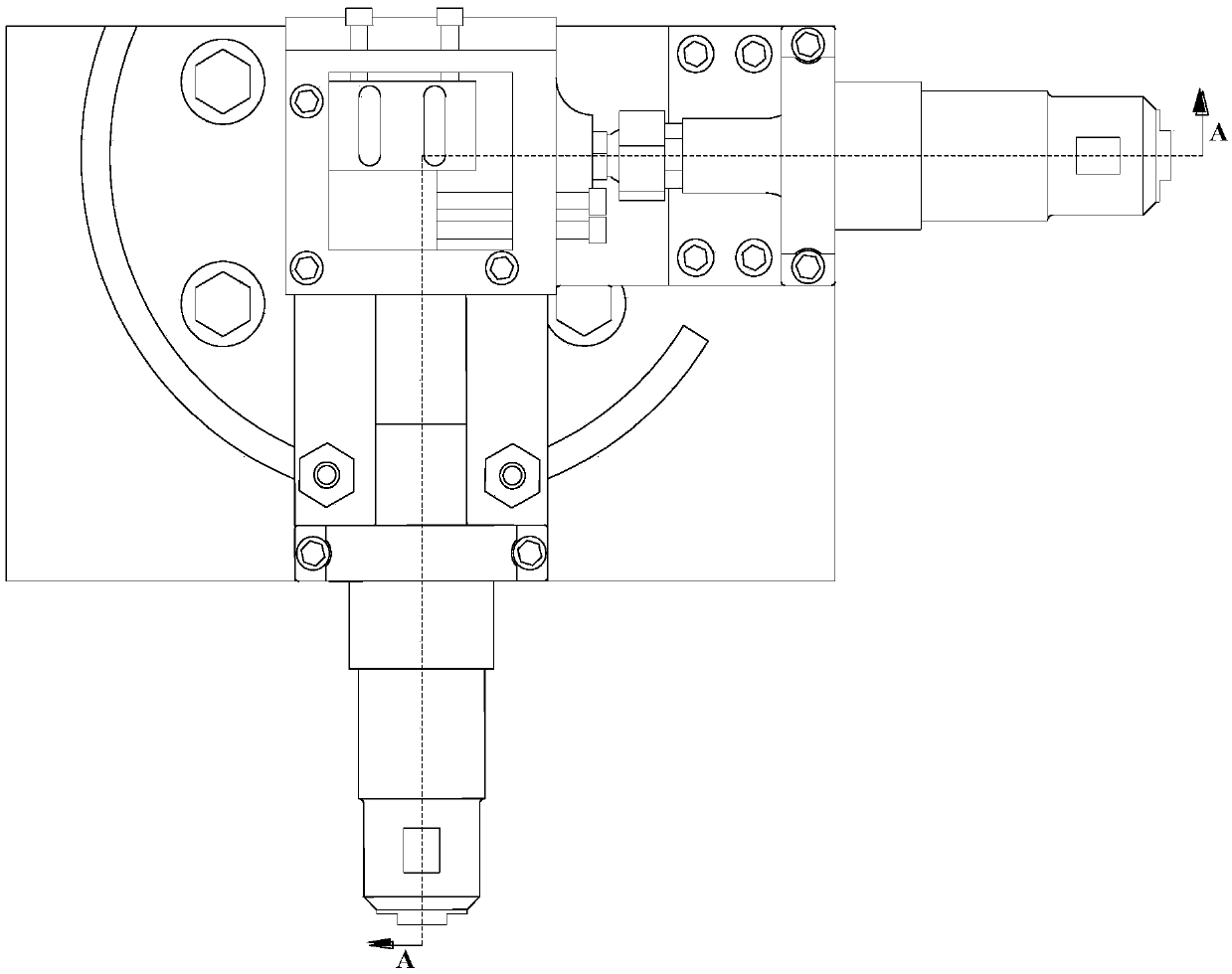

[0065] The first embodiment of the present invention is Figures 1 to 4 , Figures 7 to 19 , Figures 20(a) to 20(c) and Figure 21 As shown, it is about the tangential direction parallel to the grinding direction and the axial coupling perpendicular to the grinding direction multi-angle two-dimensional ultrasonic vibration assisted nanofluid micro-lubrication grinding device and its grinding force and grinding temperature measurement device.

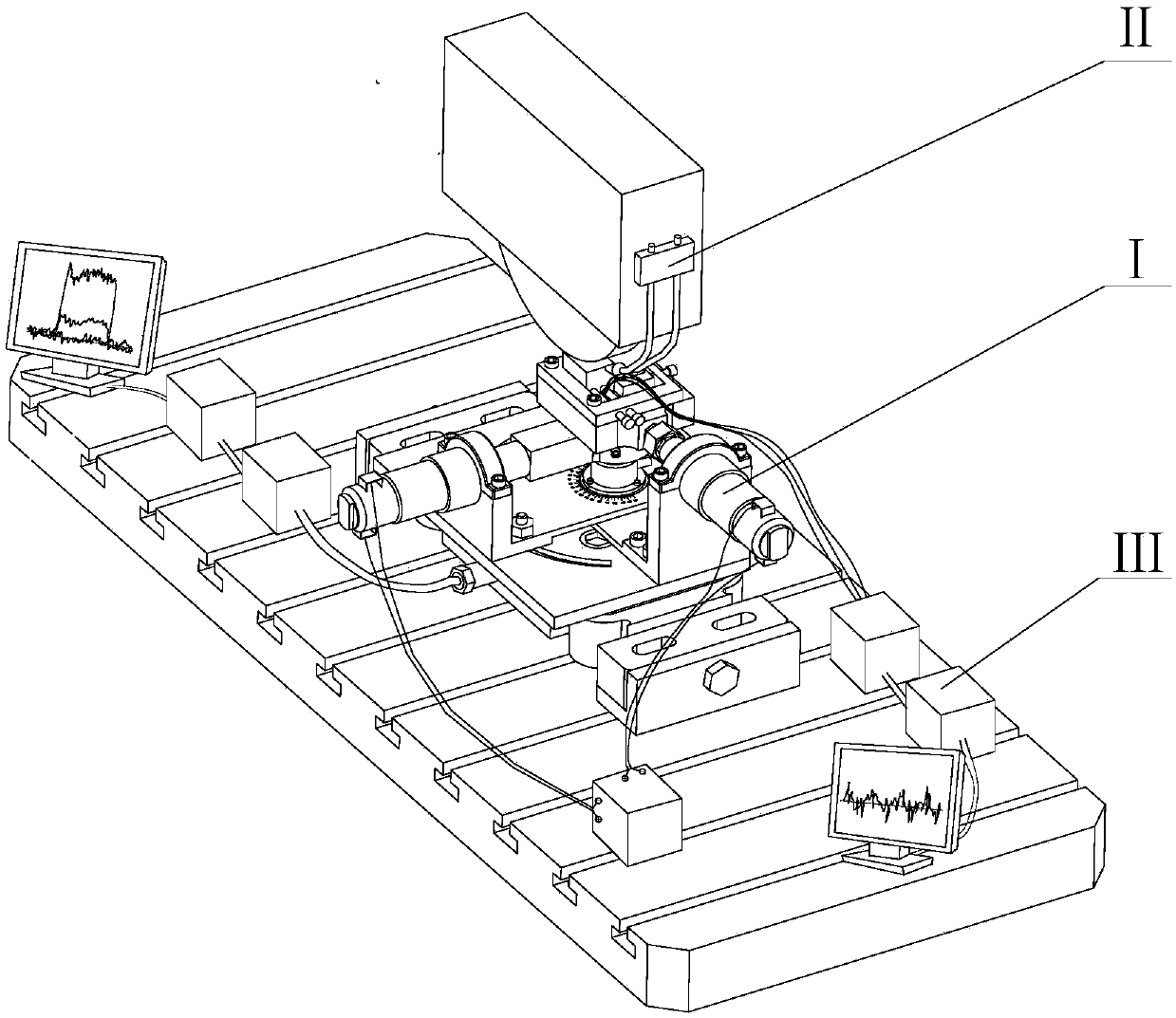

[0066] like figure 1 As shown, the multi-angle two-dimensional ultrasonic vibration-assisted nanofluid minimal quantity lubrication grinding device and its grinding force and grinding temperature measurement device are composed of multi-angle two-dimensional ultrasonic vibration device I, nanofluid minimal quantity lubrication grinding device II and grinding force , Grinding temperature measuring d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com