Machine grinding disc tool

A grinding disc and tooling technology, which is applied in the field of processing tooling, can solve the problems of difficult processing, easy wear of the cutter head, and suboptimal processing methods, and achieve the effects of low manufacturing cost, uniform grinding, and avoiding blind areas of grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

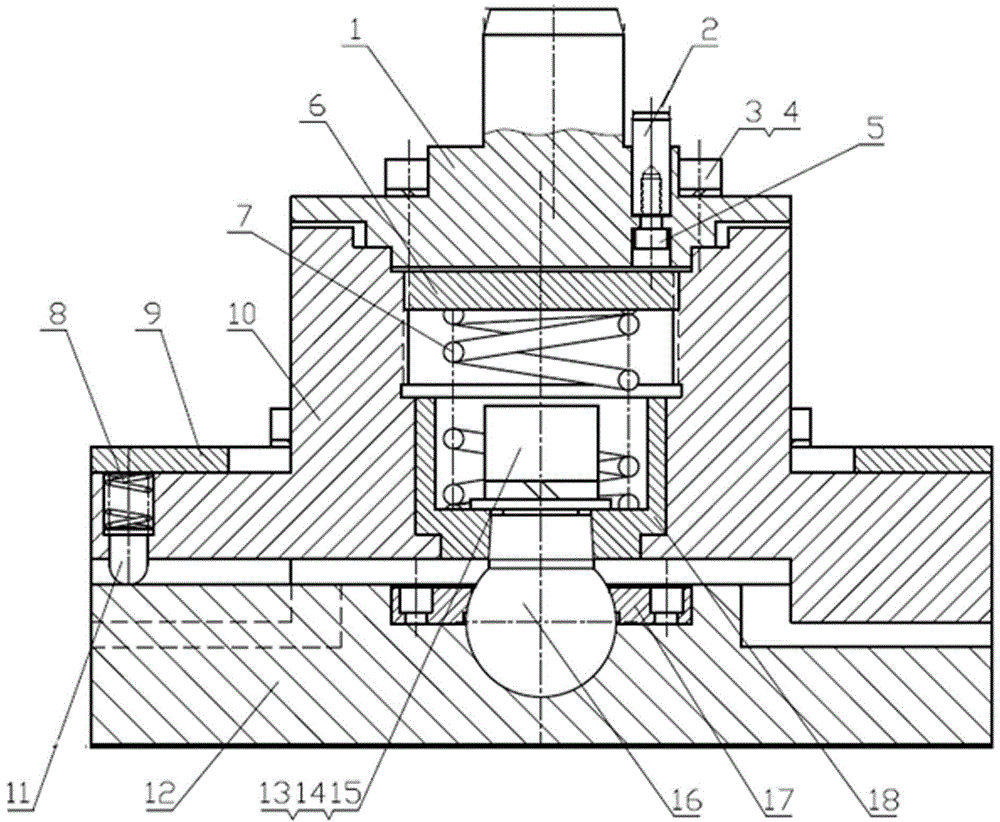

[0023] Specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0024] Such as figure 1 As shown, it is an embodiment of a mechanical grinding disc tooling used for the control rod shell nozzle flange and its sealing surface of the high-temperature reactor top cover assembly. The tooling is divided into upper and lower parts, and the upper part contains the spindle interface for mechanical connection 1 and a pressing structure, the lower part contains a grinding disc 12.

[0025] The spindle interface 1 includes a disc-shaped base and a connecting rod vertically arranged on the central axis of the top surface of the base. The end of the connecting rod is provided with a circular 45-degree chamfer. The spindle interface 1 is mechanically connected to the machine tool spindle through the connecting rod.

[0026] The main shaft interface 1 is provided with a through hole that runs through the base of the main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com