A small hole extractor

An object and outer sleeve technology, applied in the field of extraction tools for objects in small holes, can solve problems such as difficult alignment, damage to objects, and difficult extraction of objects, and achieve the effect of improving work efficiency and flexible use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

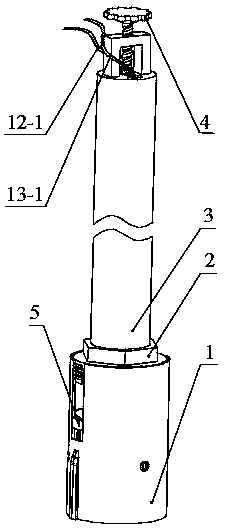

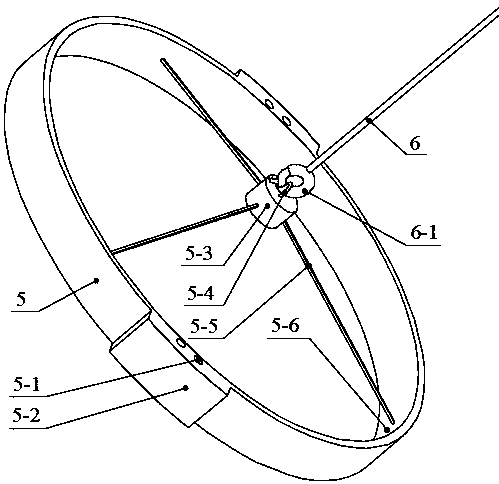

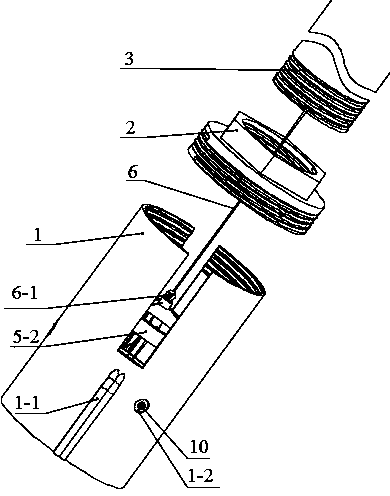

[0033] The invention relates to a small-hole object extractor, which mainly includes an object extractor and an auxiliary device. The pick-up device includes: connecting pipe 3, pull wire 6, handle 4, joint 2, inner sleeve 7, outer sleeve 1, elastic cloth 11, thin wire 9 and inner ring 5. The auxiliary device includes a camera 12 and a lighting lamp 13 . During the fetching process, firstly, the fetching device covers the fetched object 14, turns the handle 4 counterclockwise, the pull wire 6 pulls the inner ring 5 to move upwards and tightens the thin thread 9, so that the elastic cloth 11 runs along the lower end of the inner sleeve 7 Get close to the middle, then hold up the object 14 from below to realize the action of fetching. The following describes the implementation and features of the present invention step by step according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com