PU trim strip production system

A production system and technology for decorative strips, which are used in spray devices, devices for coating liquid on surfaces, and metal processing. It can solve problems such as damage to the respiratory system, deformation, mildew, etc., and achieves light weight, good hardness, and strong artistry. , the effect of strong fire performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

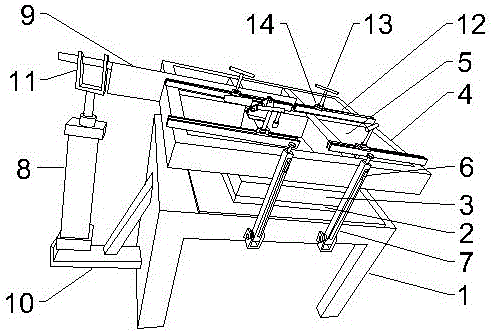

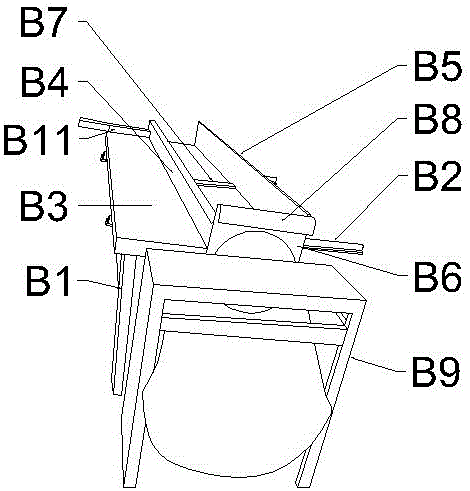

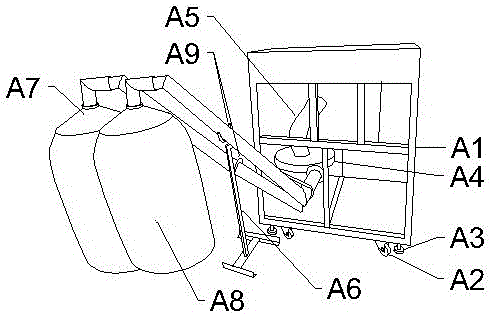

[0011] Below in conjunction with all accompanying drawings the present invention will be further described, and preferred embodiment of the present invention is: see appended figure 1 to attach Figure 5 , the PU decorative strip production system described in this embodiment includes a shaping die connected by a conveyor belt, a cut-to-length sawing device, an edge planer and a spraying device, and the shaping die includes a base 1, and the top of the base 1 is provided with Backing plate 2, the top of the backing plate 2 is provided with a mold 3, and the top of the mold 3 is provided with a press frame 4. The main body of the press frame 4 is a frame formed by connecting metal square tubes. The inner frame is separated by the inner frame to form several positioning areas 5, horizontal support arms 9 are provided at both ends of the press frame 4, power frames 10 are fixed on both sides of the base 1, and a lifting cylinder 8 is provided on the top of the power frame 10. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com