Novel roller type flat die machine

A roll-type, flat-die technology, applied in presses, presses using rotating pressure components, manufacturing tools, etc., can solve the problem of low plastic adhesion of biomass raw materials, large mold edge wear, large mold wear and consumption, etc. problems, to achieve the effect of improving wear resistance, improving production capacity, and improving comprehensive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the drawings and embodiments, but it is not a basis for limiting the present invention.

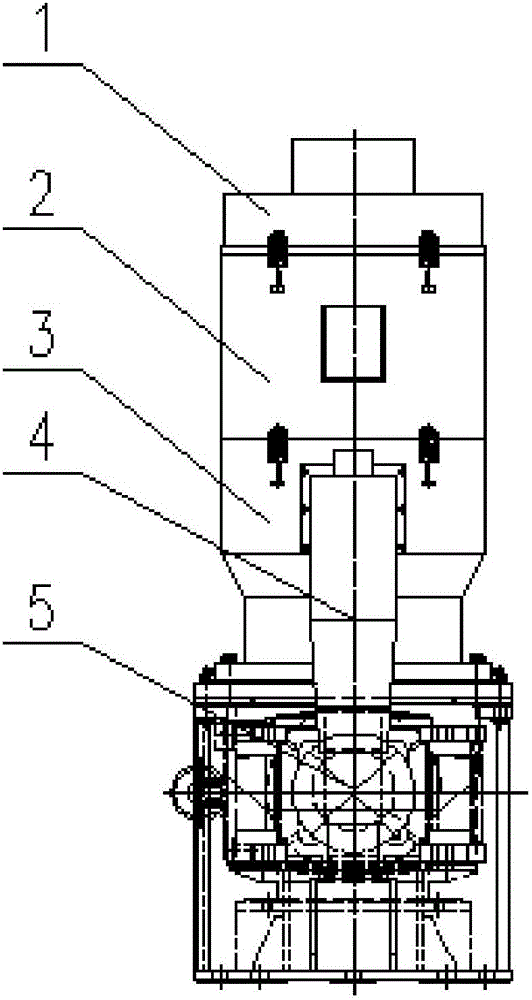

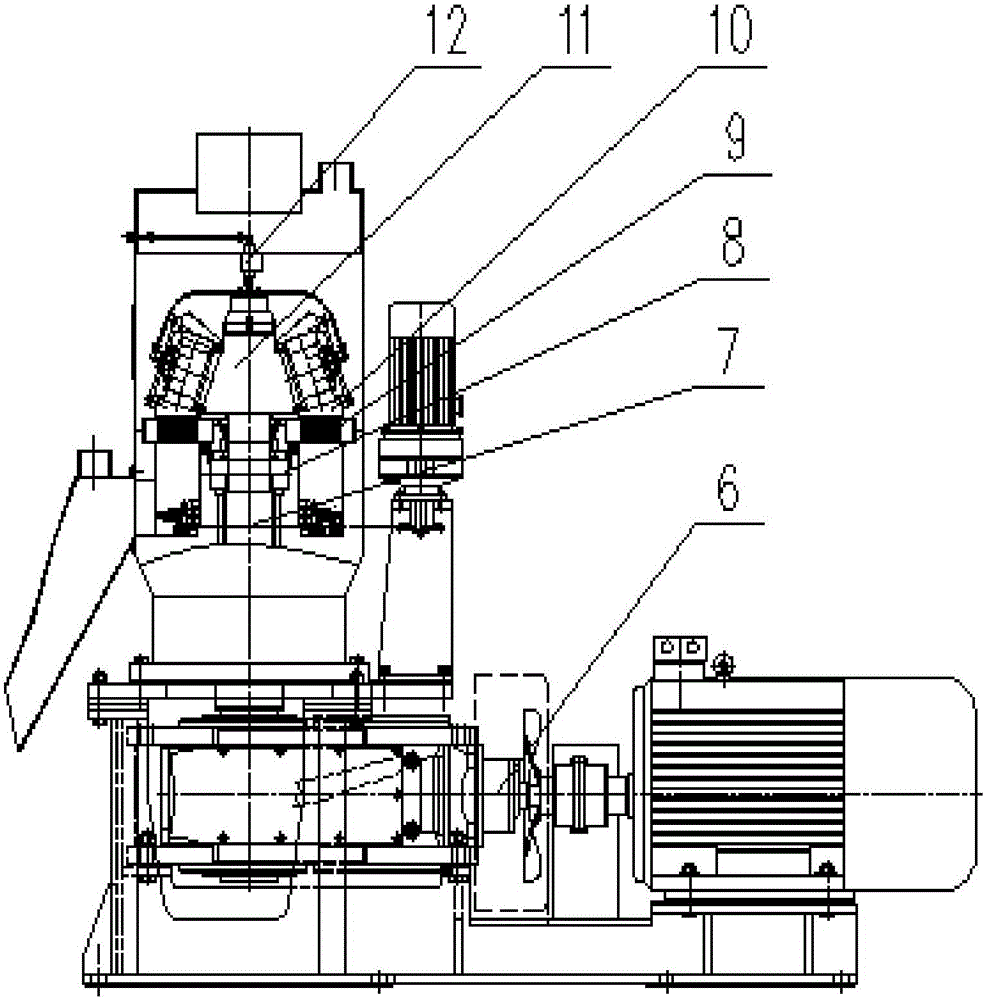

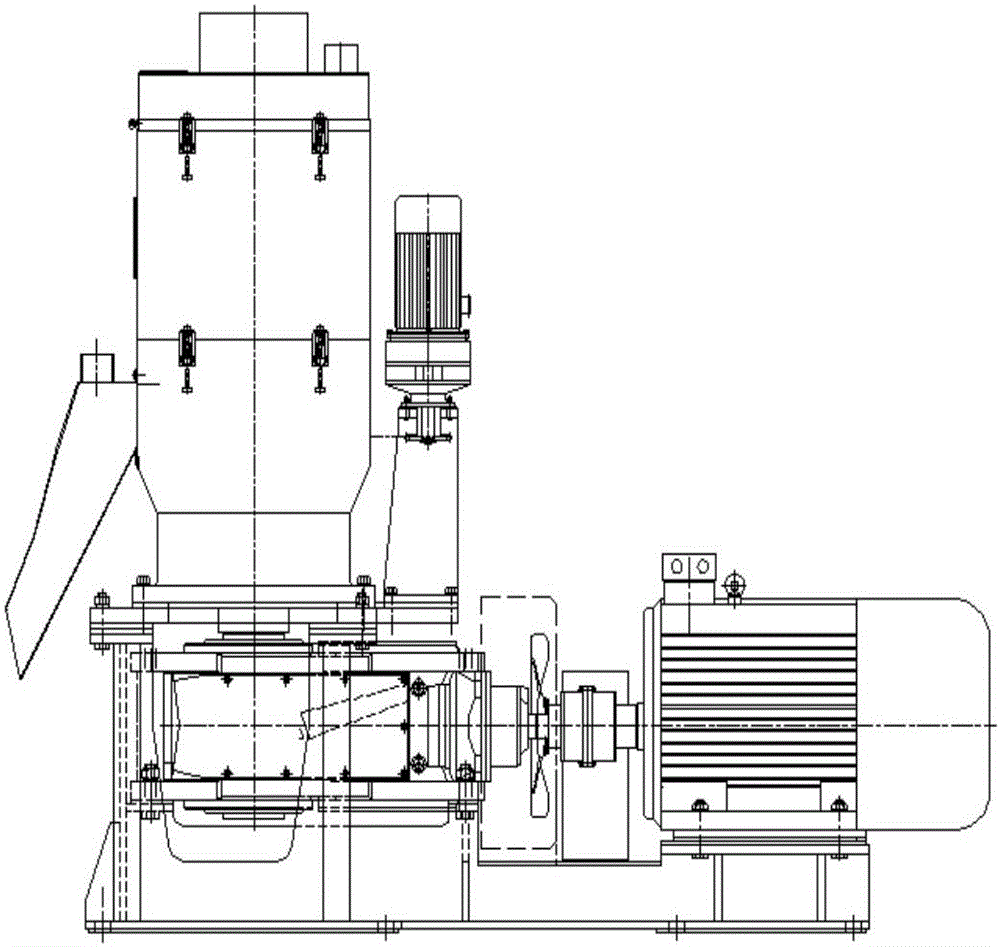

[0033] Examples. A new type of roller flat die machine, composed as figure 1 , 2 As shown in and 3, including the frame 5, the frame 5 is provided with a body 3, the top of the body 3 is provided with a lower cover 2 and an upper cover 1, and the side of the body 3 is provided with a hopper 4; the body 3 has a plurality of supporting devices 8 is provided with a transmission shaft 7, the lower end of the transmission shaft 7 is connected with a transmission device 6, the upper end is provided with a shaft head seat 11, a pressing roller device 10 is provided on the shaft head seat 11, and a bottom mold 9 is fitted under the pressing roller device 10. A lubrication device 12 is arranged above the pressing roller device 10; it can periodically lubricate the required points and meet the requirements of the operatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com