Satellite-type flexographic printing machine

A technology of printing presses and flexo plates, applied in printing presses, rotary printing machines, rotary printing machines, etc., can solve the problems of high production and labor costs, production efficiency and product qualification rate reduction, and improve production efficiency and operators Small quantity, avoid the effect of printing tail

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

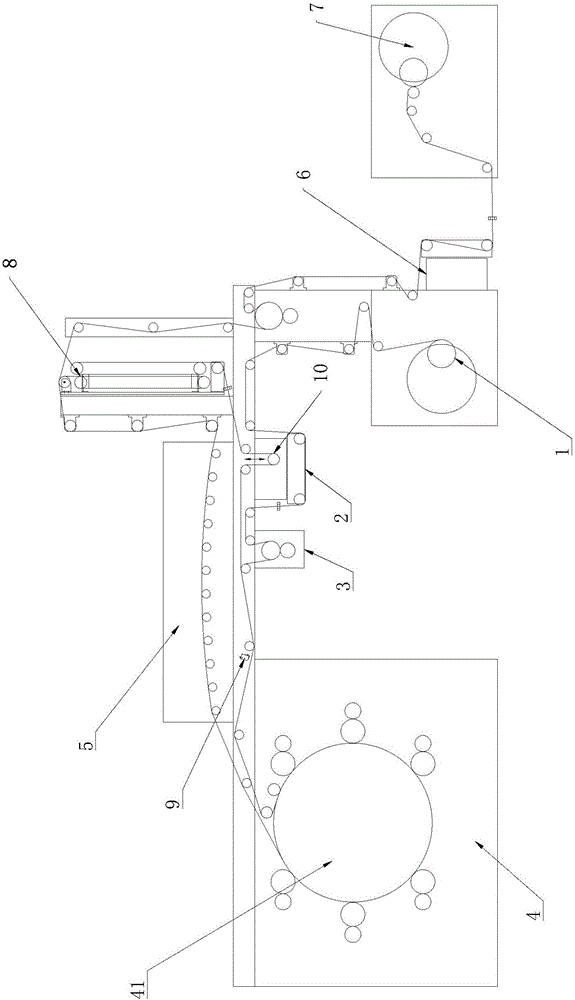

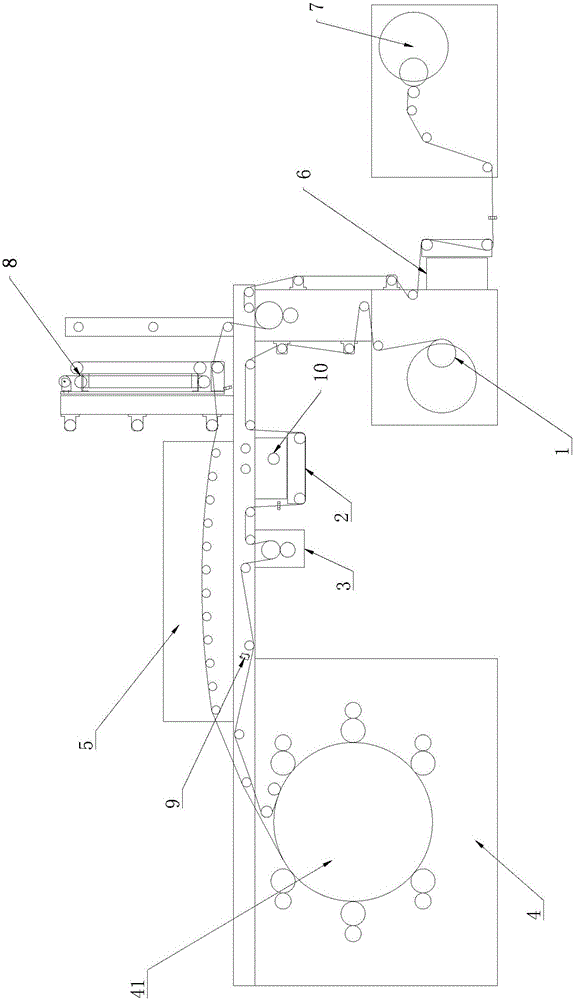

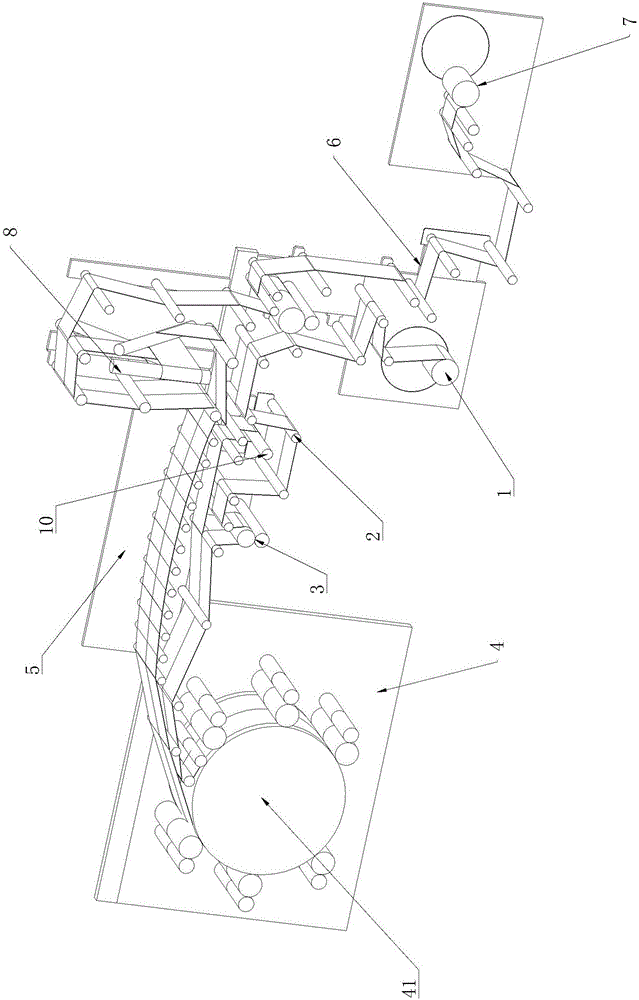

[0015] refer to figure 1 , figure 2 , image 3 , Figure 4 , a kind of satellite type flexographic printing machine of the present invention, described printing machine can carry out double-sided printing also can carry out single-sided printing; Said printing machine comprises unwinding unit 1, unwinding correction unit 2, traction unit 3, Printing station 4, oven 5, winding deviation correction unit 6, winding unit 8; printing materials are wound on the unwinding unit 1, and the printing materials are released by the unwinding unit 1 and passed through the unwinding deviation correction unit in turn After being corrected by the unit 2 and pulled by the traction unit 3, it enters the printing station 4 for front printing, and the printed material is sent to the oven 5 for the first drying after being printed on the front; The printed material after drying for the first time will be directly sent to the winding correction unit 6 for correction operation before winding, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com