Manufacturing method for 3D ceramic tile picture and ceramic tile printed with 3D pictures and words

A production method and ceramic tile technology, which are applied in the production of special varieties of printed matter, such as printing, post-printing, copying/marking methods, etc., can solve the problems of long production cycle, easy to be damaged, and time-consuming, and achieve vivid and realistic graphics and texts. , has the effect of convex and concave feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

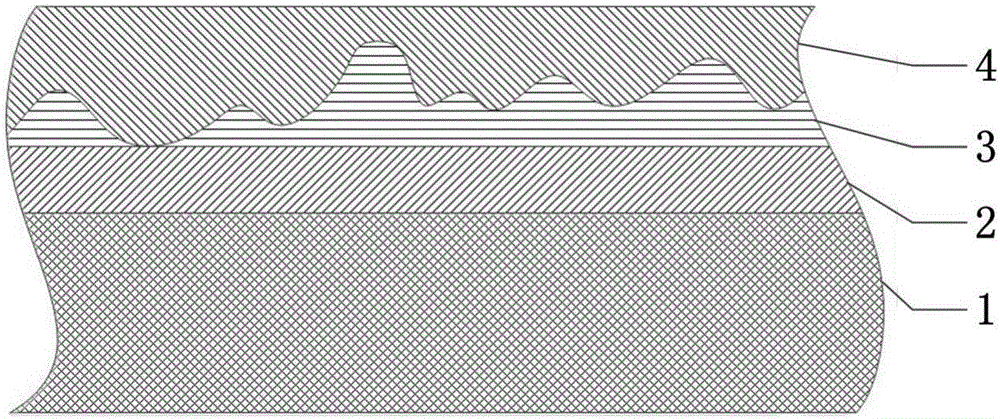

[0017] The following is attached figure 1 , to further illustrate the specific implementation of the 3D ceramic tile painting production method of the present invention. The manufacturing method of 3D tile painting of the present invention is not limited to the description of the following examples.

[0018] A method for making a 3D tile painting, comprising the following steps:

[0019] (1) Clean the surface of the tiles to be printed;

[0020] (2) Spraying the base layer coating on the surface of the ceramic tile, so that the surface of the ceramic tile has good ink adhesion; a photocuring agent needs to be added in the ceramic tile printing coating, and the two are fully mixed according to the volume ratio of 10:1;

[0021] (3) Carry out 3D layering of the graphics to be printed, and spray UV ink layer by layer on the base layer of the tile to realize the layered accumulation of UV ink until all the layers of the printed graphics are sprayed, showing a three-dimensional m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com