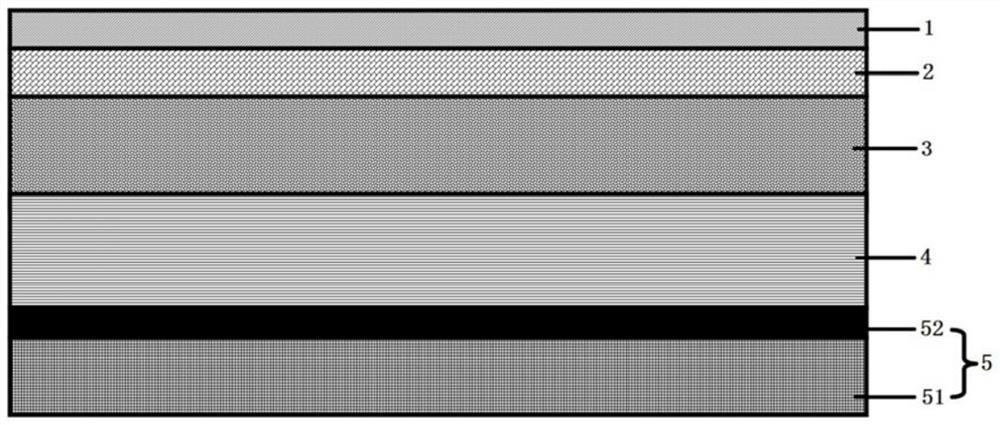

A flame-retardant, heat-insulating and cooling-proof, waterproof synthetic leather for tarpaulins and its preparation method

A technology of synthetic leather and flame-retardant polymers, applied in non-woven fabrics, filament/thread forming, transportation and packaging, etc., can solve the problems of flame retardancy, heat insulation, and poor sun protection effects, and avoid excessive temperature rise Fast, well-selected radiation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Preparation of synthetic leather for flame-retardant, heat-insulating and cooling, sun-proof and waterproof tarpaulins, the base fabric is made of 100% polyester fiber woven fabric (the warp and weft yarn raw material is polyester yarn, the warp and weft yarn specification is 30tex, and the warp density is 280 pieces / 10cm, weft yarn is 200 pieces / 10cm), including the following steps:

[0064] S1. Immerse the base cloth in 8g / L sodium dodecylbenzenesulfonate solution, heat it in a water bath to 60°C, and stir it magnetically for 10 minutes. Take out the base cloth and rinse it with deionized water to remove impurities on the surface of the base cloth.

[0065] S2. Select aramid fiber 1313 and vacuum dry it, then place it in DMAc / LiCl (mass ratio 91:9) ionic liquid, and heat it with magnetic stirring at 60°C for 6 hours until it is completely dissolved to form a spinning solution. After defoaming, it is injected into the electrospinning device, and the base cloth covered...

Embodiment 2

[0075] Preparation of synthetic leather for flame-retardant, heat-insulating and cooling, sun-proof and waterproof tarpaulins. The base fabric is made of 100% cotton fiber woven fabric (the warp and weft yarn raw material is pure cotton yarn, the warp and weft yarn specification is 28tex, and the warp density is 210 threads / 10cm, the weft is 150 threads / 10cm), including the following steps:

[0076] S1. Immerse the base fabric in 10g / L sodium dodecylbenzenesulfonate solution, heat it in a water bath to 50°C, and stir it magnetically for 12 minutes. Take out the base fabric and rinse it with deionized water to remove impurities on the surface of the base fabric.

[0077] S2. Select aramid fiber 1313 and vacuum dry it, then place it in DMAc / LiCl (mass ratio 91:9) ionic liquid, and heat it with magnetic stirring at 60°C for 6 hours until it is completely dissolved to form a spinning solution. After defoaming, it is injected into the electrospinning device, and the base cloth cove...

Embodiment 3

[0087] Preparation of synthetic leather for flame-retardant, heat-insulating and cooling, sun-proof and waterproof tarpaulins. The base fabric is made of 100% aramid fiber woven fabric (the warp and weft yarns are made of aramid filaments, the warp and weft yarn specifications are 28tex, and the warp and density 270 threads / 10cm, weft yarn is 180 threads / 10cm), including the following steps:

[0088] S1. Immerse the base cloth in 9g / L sodium dodecylbenzenesulfonate solution, heat it in a water bath to 40°C, and stir it magnetically for 15 minutes. Take out the base cloth and rinse it with deionized water to remove impurities on the surface of the base cloth.

[0089] S2. Select diamine (ODA) and pyromellitic dianhydride (PMDA) and vacuum-dry them, then place them in DMAc / LiCl (mass ratio 91:9) ionic liquid, and heat with magnetic stirring at 65°C for 6 hours until completely dissolved to form a polyamic acid (PAA) spinning solution, vacuum defoaming and injecting into an elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com