Tire changer

A technology of tire changer and disassembly mechanism, which is applied in tire installation, tire parts, transportation and packaging, etc., can solve the problems of inability to realize on-board and large volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

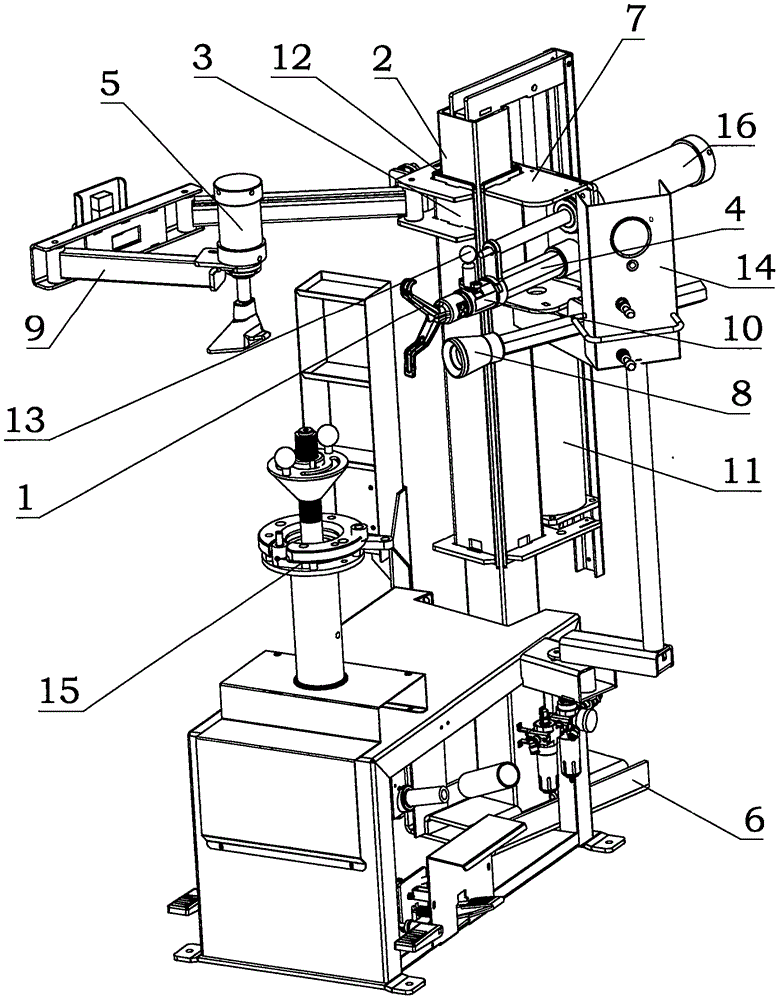

[0007] Below in conjunction with accompanying drawing, the present invention will be further described;

[0008] The body is composed of an operating platform and a disassembly mechanism. On the operating platform, there is a wheel hub fixed disk 15. There is a button switch 14 on one side of the operating platform. There is a square tube slideway foot fixing groove 6 at the bottom of the outer side of the operating platform, and a square tube slideway 2 is provided on the square tube slideway foot fixing groove. One side tube sliding sleeve 3 is set outside the square tube slideway. There is a fixed mount 7 on the top of the square tube sliding sleeve, and on the fixed mount, the tire pressure booster arm 9 has a tire pressure cylinder 5 at the front end of the tire pressure booster arm. A slide block 12 is inlaid between the square tube sliding sleeve and the square tube slideway. The hook head walking cylinder 16 is housed on the top of the fixed mount, and the hook hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com