A cold molding press for the production of car roofs

A car roof and cold molding technology, which is applied in lamination, vehicle parts, lamination devices, etc., can solve the problems of low efficiency, achieve good bonding performance, improve efficiency, and protect the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

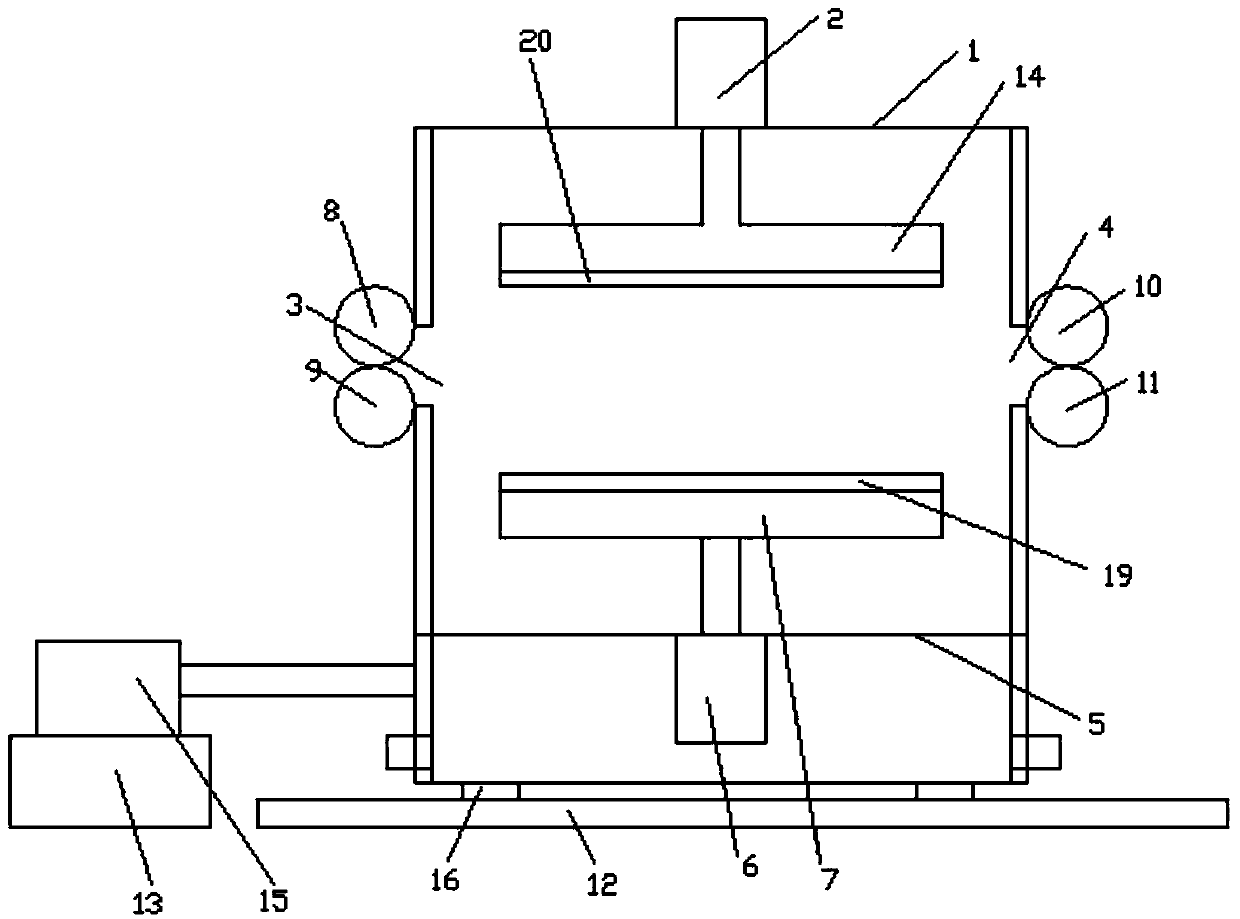

[0017] Please refer to Figure 1-2 , the present invention provides a cold molding press for producing the roof of an automobile, comprising a box body 1, an upper cylinder 2 is arranged on the top of the box body 1, and an upper pressure plate 14 is arranged on the top of the box body 1 through the air rod of the upper cylinder 2; The front end of the box body 1 is provided with a feed port 3, the rear end of the box body 1 is provided with a discharge port 4, the lower part of the box body 1 is provided with a support plate 5, the lower end surface of the support plate 5 is provided with a lower cylinder 6, and the air rod of the lower cylinder 6 passes through Set the lower pressure plate 7 through the support plate 5; set the feeding upper pressure roller 8 and the feeding lower pressure roller 9 on the box body 1 at the feeding port 3, and set the discharging upper pressing roller on the box body 1 at the material outlet 4 10 and the discharge lower pressure roller 11, in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com