Steering gear rack support bushing structure

A steering gear and rack technology, used in steering gears, steering mechanisms, mechanical steering gears, etc., can solve the problems of high mechanical noise of steering gears, and achieve the effects of solving mechanical impact noise, reducing contact area, and preventing friction noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, the present invention will be further described:

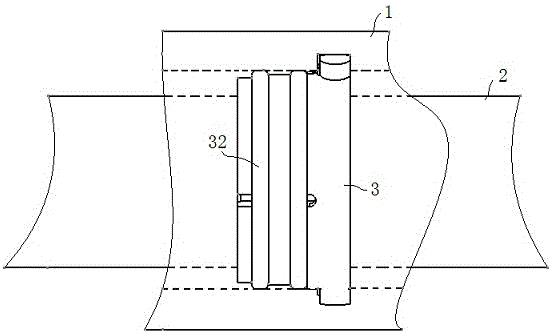

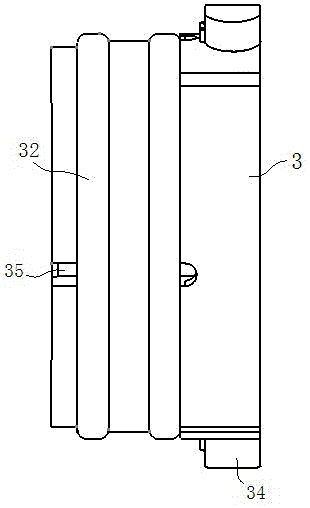

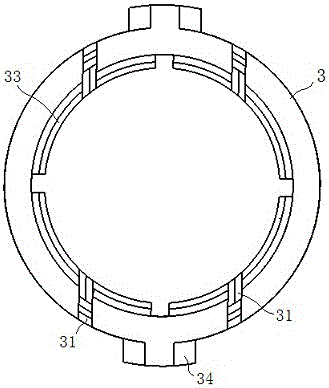

[0025] Figure 1 to Figure 4 Shown is a steering gear rack supporting bushing structure, including a steering gear rack supporting bushing assembly 3, the steering gear rack supporting bushing assembly 3 includes a steering gear rack supporting bushing body and a The rack supports the rubber ring 32 on the outer cylindrical surface of the bushing body. One end of the steering gear rack support bushing body is provided with a radial clamping boss 34, such as figure 2 shown. Such as image 3 As shown, four grease storage tanks 31 are also processed on the end face of the steering gear rack support bushing body, and the grease storage tanks 31 communicate with the lubricating oil grooves 33 on the inner wall of the steering gear rack support bushing body. The longitudinal centerline of the grease storage tank 31 is arranged obliquely relative to the radial direction of t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap