A Variable Structure Two-Dimensional Supersonic Inlet Adjustment Mechanism

An adjustment mechanism and supersonic technology, which is applied to the combustion of the intake port of the power unit, aircraft parts, and power units on the aircraft, etc., can solve the problems of unguaranteed air flow quality, unstable air flow, and difficult processing, etc. Airway priming problems, ensure normal operation, ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

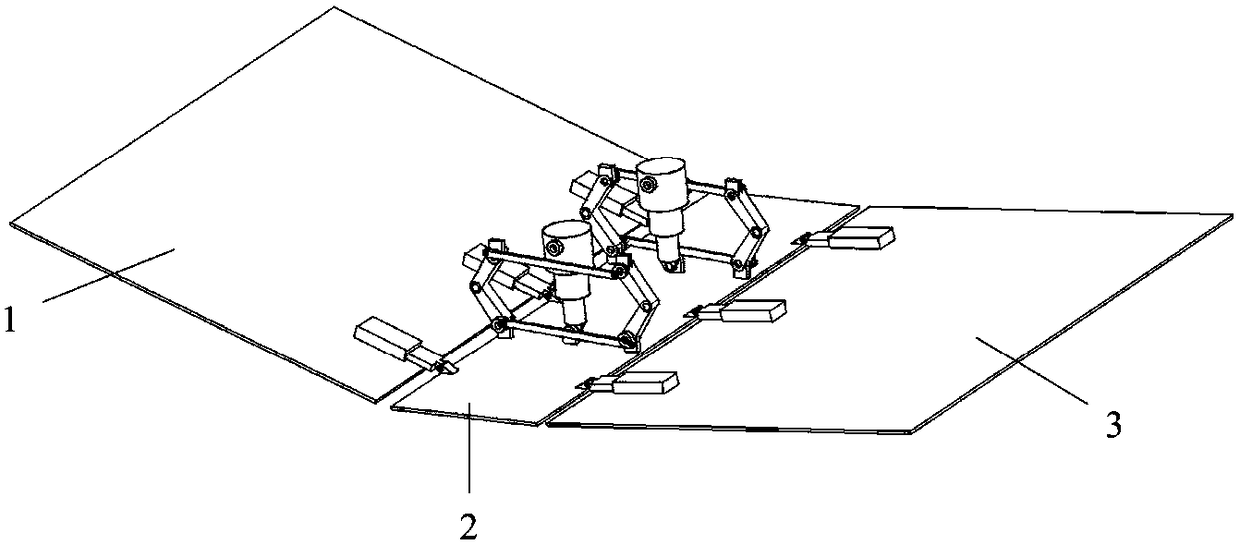

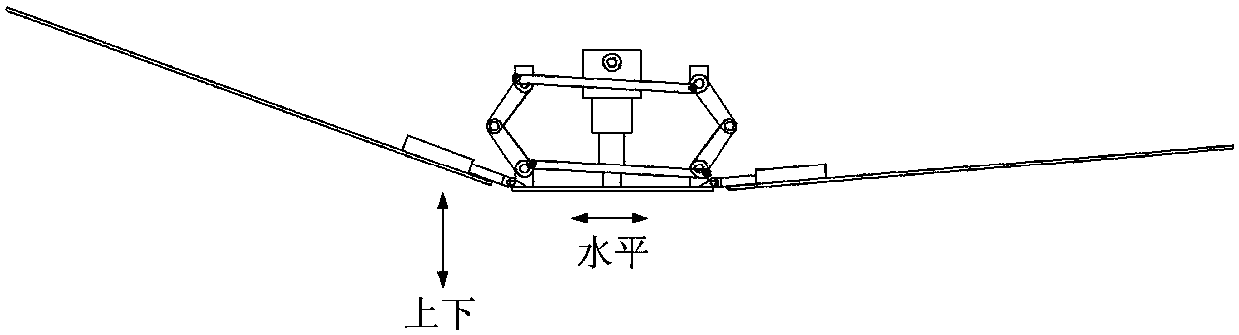

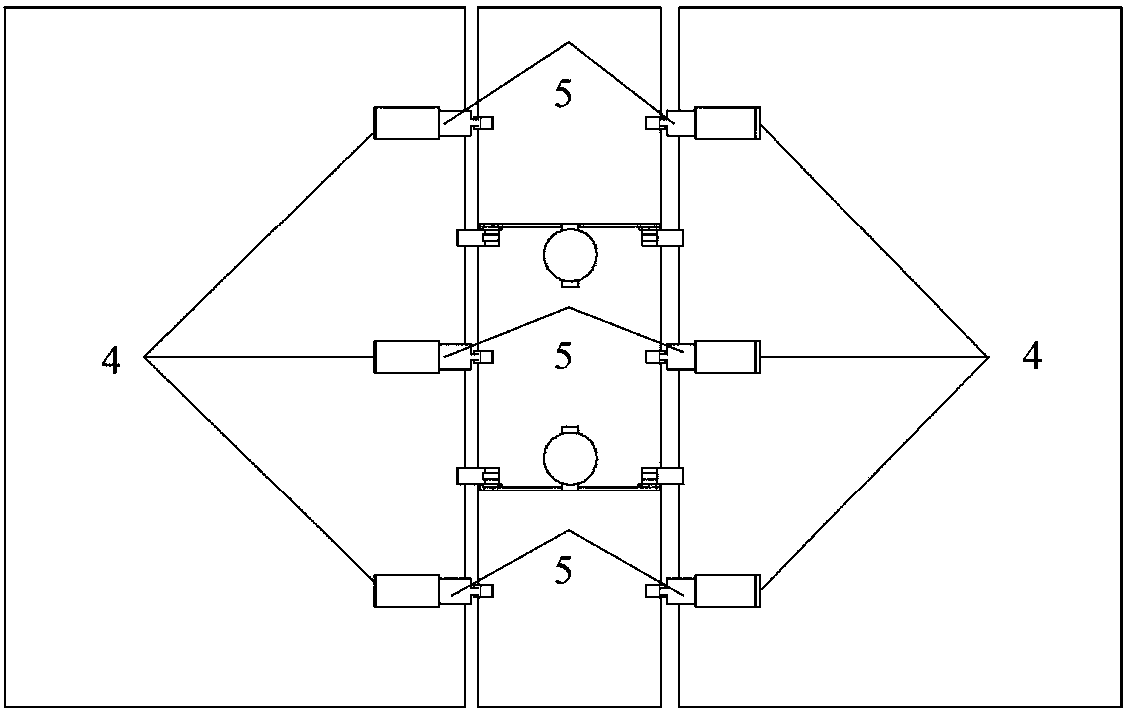

[0022] This embodiment is a variable-structure two-dimensional supersonic inlet regulating mechanism. The air inlet changes the compression angle and throat height of the precursor compression plate according to the flight state of the hypersonic air-breathing aircraft, so as to ensure the starting performance and better working state of the air inlet operating in a wide Mach number range. For the starting performance, the intake port needs to have a sufficient contraction ratio to ensure the compressibility of the intake port, but if the contraction ratio is too large, the intake port will be blocked. At this time, change the compression angle of the front body compression plate or the throat The height can effectively solve the problem of shrinkage ratio; while ensuring the starting performance, ensure that the air inlet is in a better working state during the working process, and ensure sufficient pressure by adjusting the compression angle of the front body compression plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com