Automatic liquid chemical filling machine of plant protection unmanned plane

A plant protection drone and automatic filling technology, which is applied in the field of plant protection drone liquid automatic filling machine, can solve the problems of laborious and troublesome manual handling, inability to do it accurately, easy spillage of liquid medicine, etc. Achieve the effect of saving manpower and material resources, easy to operate, and avoiding dripping and leaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

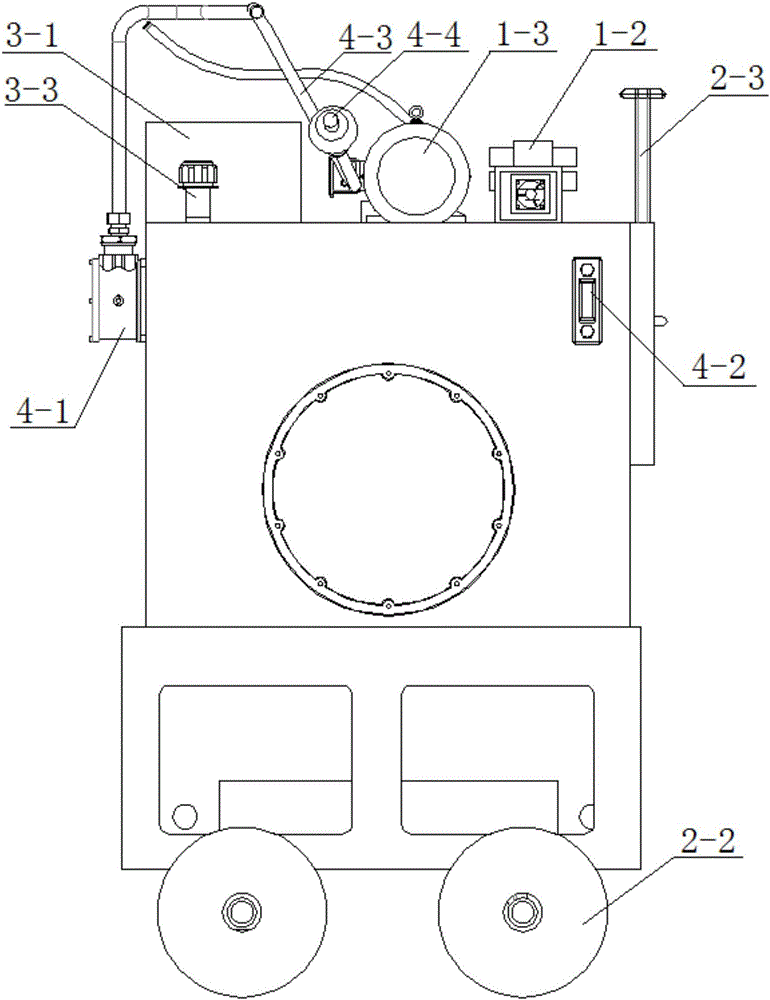

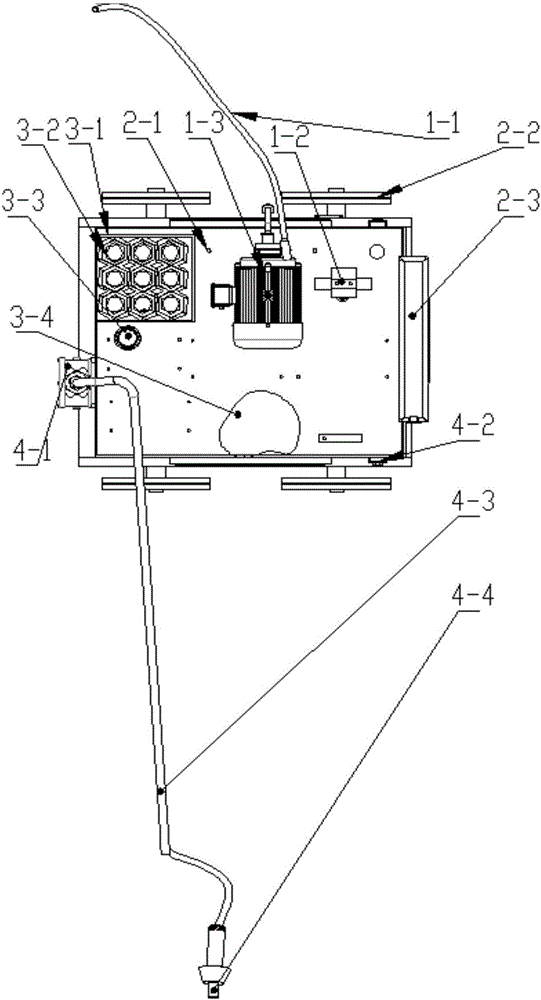

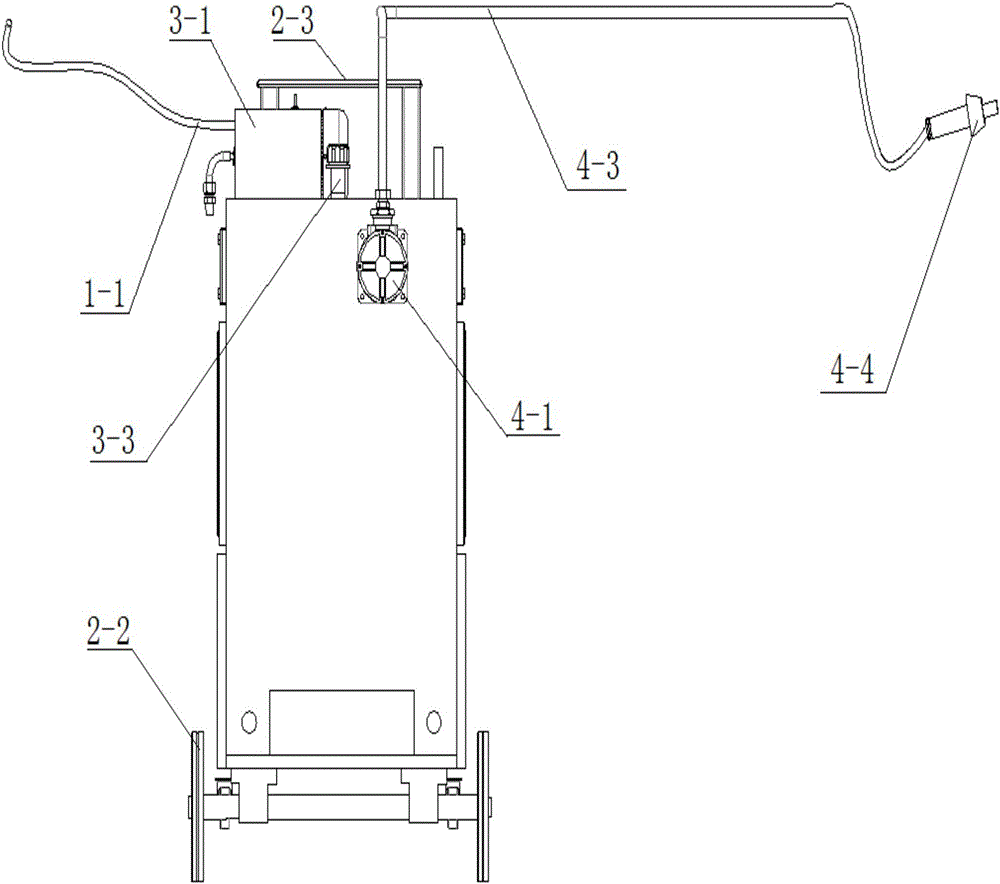

[0022] Embodiment 1: as Figure 1 to Figure 3 The automatic liquid filling machine for plant protection drones shown includes a water supply device, a storage device, a medicine box device, and a liquid discharge device. The water supply device includes a water suction pipe, a micropump connected to the water suction pipe, and a program-controlled controller for controlling the micropump , the storage device includes a box body and a stirring mechanism located in the box body, a medicine box device, and a liquid outlet device includes an intelligent driver, a guide pipe, and a grease nozzle with a meter filling device; the water suction pipe is connected to the external water tank, so The program-controlled controller controls the micro-pump to pump water into the tank of the storage device, and the stirring mechanism stirs the liquid medicine, additives and water added to the tank to form a mixed medicine liquid, which enters the guide pipe under the drive of the intelligent d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com