Autonomous vaporization management method and liquid ammonia micro-propulsion system

A micro-propulsion and liquid ammonia technology, which is applied to the propulsion system devices of aerospace vehicles, jet propulsion devices, machines/engines, etc., can solve the problems of high drop pressure ratio, unstable thrust, low specific impulse, etc., and reduce the complexity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The on-orbit maneuverability of micro-nano-satellites is an important factor in determining their mission functions, and the micro-propulsion system is the core actuator for implementing orbital maneuvers. Micro-nano satellites have limited overall star resources, and the structure, volume, power consumption, and propulsion fluid of their propulsion systems are all subject to high constraints, which are obviously inferior to conventional satellites. Therefore, the performance of conventional propulsion systems is difficult to meet the needs of micro-nano satellites, which has become the main limiting condition for the expansion of on-orbit applications of micro-nano satellites.

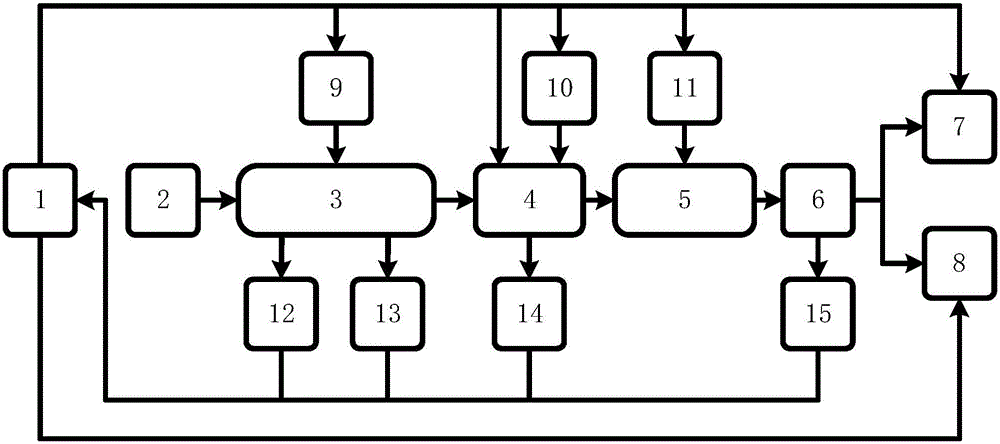

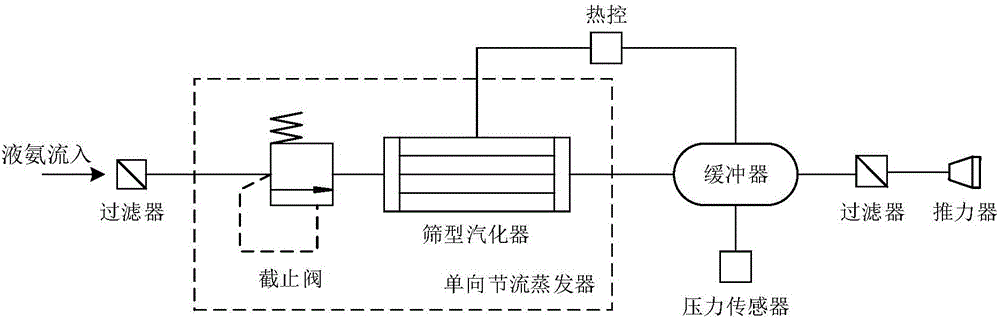

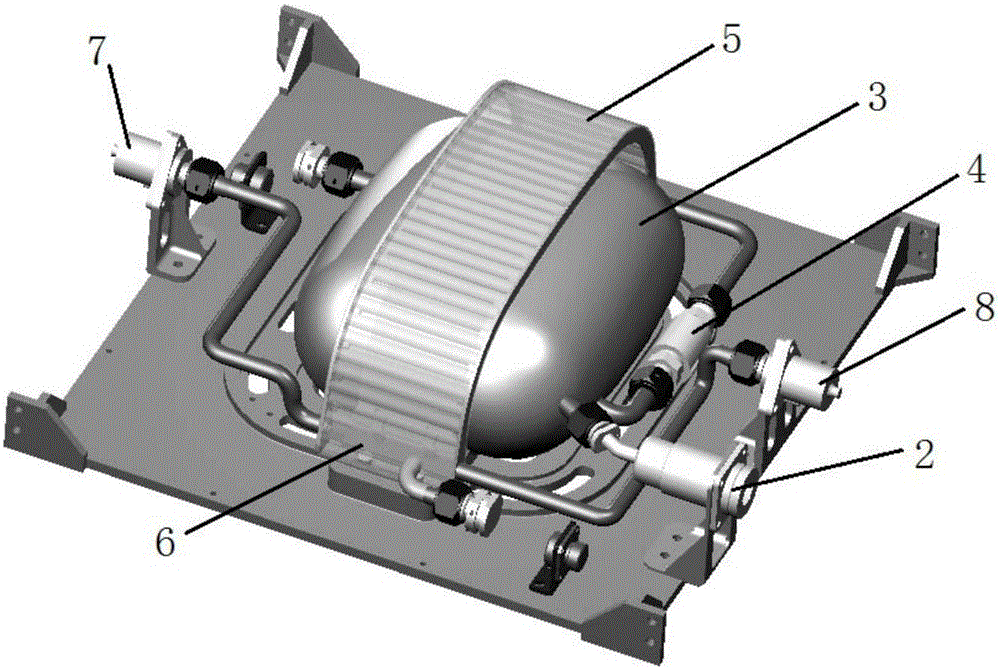

[0022] refer to Figure 1-5 , the autonomous vaporization management liquid ammonia micro-propulsion system of the present invention includes an MCU controller 1, an isolation valve for addition and discharge 2, a storage tank 3 for containing liquid ammonia propellant, a shut-off valve 4, a si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com