Magnetism-isolating rod tray recovery device for magnetism-isolating rod tray feeding mechanism

A recovery device and pallet technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as low work efficiency, affecting production efficiency, and potential safety hazards, and achieve high work efficiency, simple structure, and long service life long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0009] see figure 1 with figure 2 , the embodiment of the present invention includes:

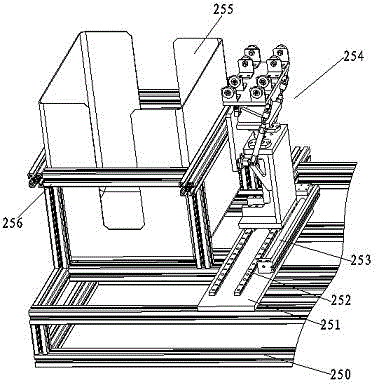

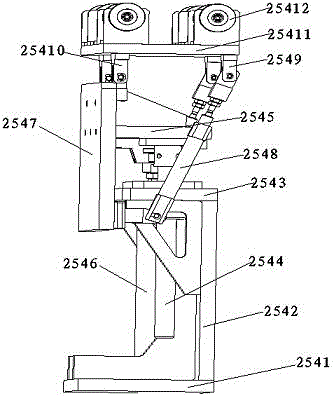

[0010] A magnetic isolation rod tray recycling device of a magnetic isolation rod tray feeding mechanism, the magnetic isolation rod tray recovery device of the magnetic isolation rod tray feeding mechanism includes an installation frame 250 installed on the ground, and the installation frame 250 is installed with Shift the bottom plate 251, two shift guide rails 252 parallel to each other are installed on the shift base plate 251, a tray recovery assembly 254 is installed on the slider of the shift guide rail 252, and the tray recovery assembly 254 includes a The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com