Novel side beam structure of elevator counterweight framework

A technology for side beams and elevators, which is applied in the field of side beam structures of new elevator counterweight frames, can solve the problems of long processing length, difficult processing, and difficult installation of counterweight blocks, and achieve the effects of reducing difficulty, increasing speed, and facilitating loading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation, structure, features and effects provided by the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

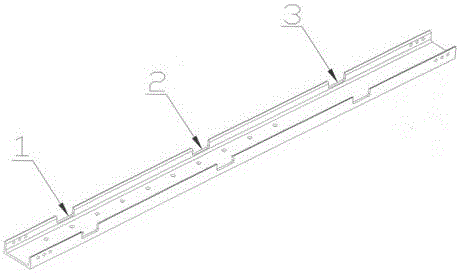

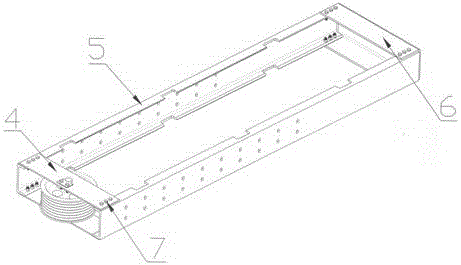

[0015] A new elevator counterweight frame side beam structure, comprising: side beam 5, rope sheave assembly combination 4, lower beam 6, said side beam 5 is an integrally formed channel steel profile, two side beams are arranged opposite to each other, two side beams A lower beam 6 is provided between the bottoms of the beams, and a rope pulley assembly 4 is provided between the tops of the two side beams. The side beams 5, the lower beam 6 and the rope pulley assembly 4 are connected by fasteners 7. Three counterweight mounting holes, namely upper counterweight mounting hole 1, middle counterweight mounting hole 2, and lower counterweight mounting hole 3, are respectively distributed on the side beam 5.

[0016] The upper counterweight installation hole 1 , the middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com