Cup mouth foundation template reinforcing and hydraulic dismounting construction process

A formwork reinforcement and construction technology technology, applied in infrastructure engineering, construction, etc., can solve the problems of poor control of the position of the cup mouth formwork, the formwork cannot be reused, and the progress of the construction period is affected, saving manpower and material resources, reliable construction quality, The effect of saving templates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

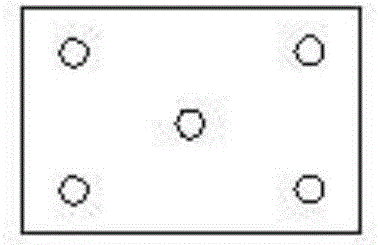

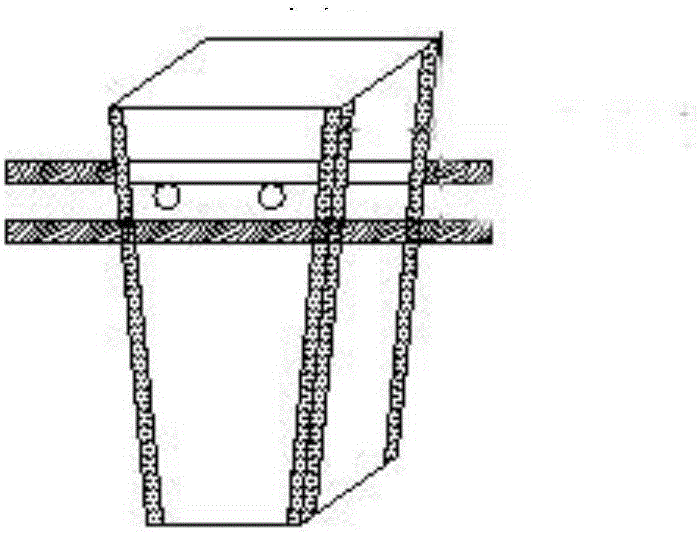

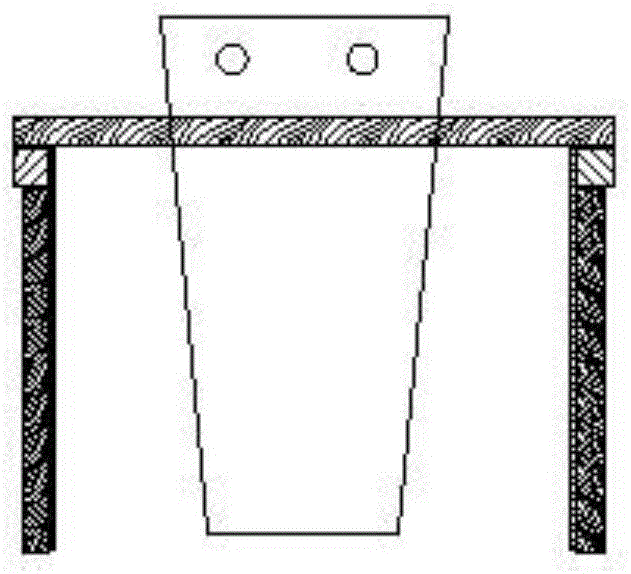

[0040] The reinforcement and hydraulic demolition construction process of the cup base formwork provided in this embodiment includes the following steps:

[0041] (1) Construction preparation

[0042] Construction preparation: review the drawings, calculate the amount of templates, draw template blanking diagrams, purchase templates and related consumables, prepare plans, train and disclose.

[0043] 1) Make drawing blanking according to the drawn template

[0044] To process the overall cup mouth template, 50×5mm galvanized angle iron must be used to wrap the edge at the external corner, and sealant should be evenly applied on the contact surface between the galvanized angle iron edge and the template to prevent the concrete slurry from immersing, affecting the appearance of the concrete surface and producing Formwork resistance.

[0045] 2) The cup formwork should be 300mm higher than the platform concrete, and a construction hole of Φ60 is drilled at 100mm with a starter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com