Connecting node for superposed sandwich wall side wall and prefabricated base plate

A technology for connecting nodes and sandwich walls, which can be used in buildings, building structures, etc., to solve problems such as poor structural strength, affecting the waterproof performance and construction quality of buildings, and being easy to break, achieving good waterproof performance, enhanced extrusion force, The effect of increasing the connection node

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

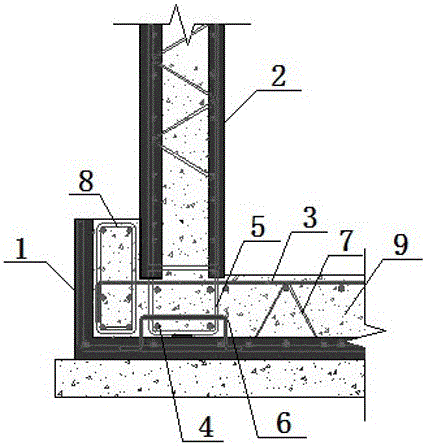

[0012] see figure 1 , the connection node between the side wall of the laminated sandwich wall and the prefabricated bottom plate of the present invention, the end of the prefabricated bottom plate is made into an L shape, and the vertical side of the end of the L-shaped prefabricated bottom plate is higher than the bottom of the side wall of the laminated sandwich wall by a certain height, and the L-shaped The outer side of the vertical edge of the end of the prefabricated floor is the soil retaining surface, and the bottom of the side wall of the laminated sandwich wall and the bottom stirrup are installed on the inner side of the end of the L-shaped prefabricated floor. Reinforcement cages, structural steel bars and horse stool bars are installed between the bottom of the wall, and are integrally formed by connecting and fixing the cast-in-place concrete between the inner side of the L-shaped prefabricated floor end and the bottom of the laminated sandwich wall. The reinforc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap