Double-yield-point linear all-steel buckling-resistant energy-consuming support

A technology of anti-buckling energy consumption and double yield points, which is applied in the direction of earthquake resistance, building components, building types, etc., can solve the problem of core energy-dissipating plate fracture, failure to realize energy dissipation in the yield section, single-core steel plate cannot meet the demand for large bearing capacity, etc. problem, to avoid fatigue damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

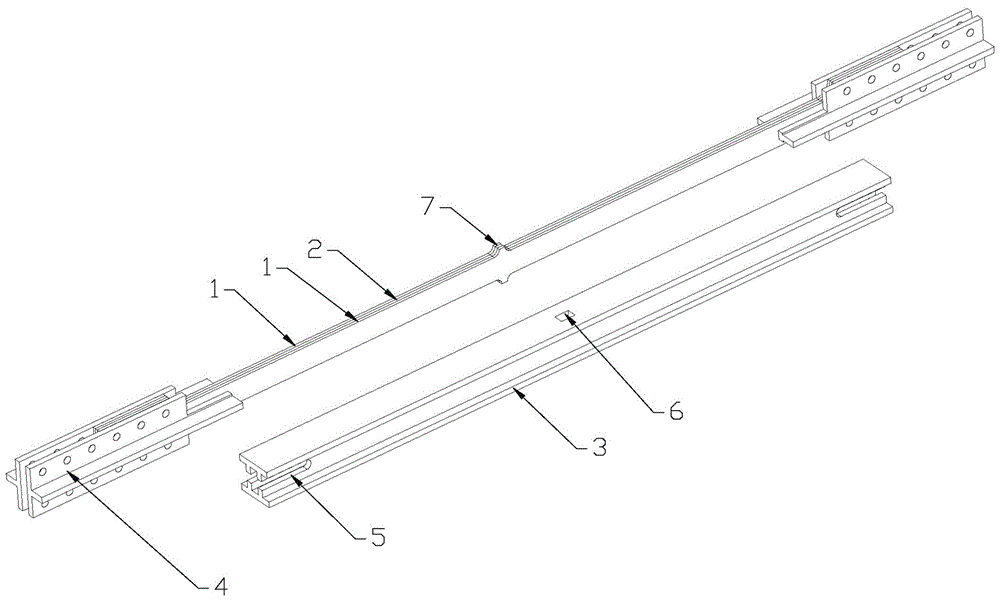

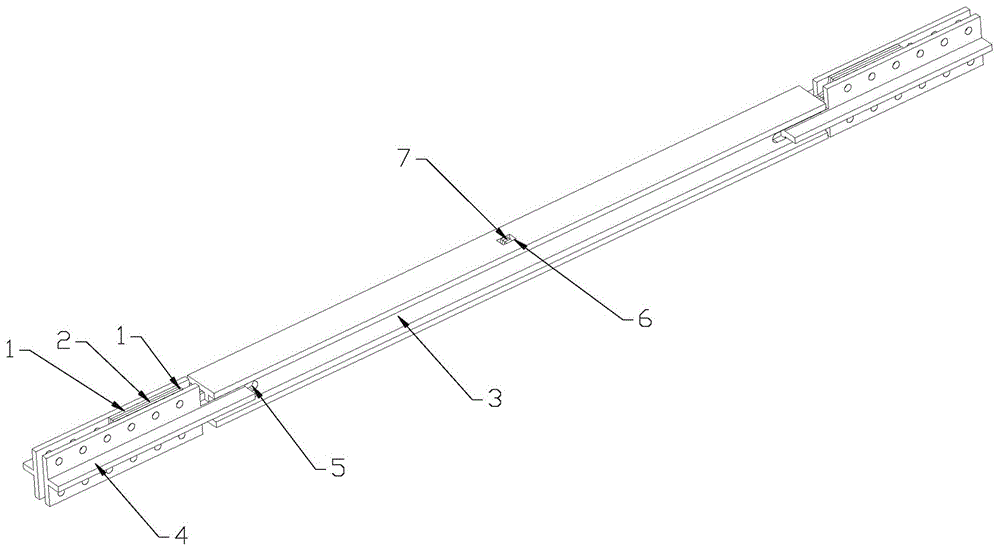

[0021] Such as Figure 1-2 Shown: a double-yield-point inline-shaped all-steel buckling-resistant energy-dissipating support, including a core energy-dissipating plate, which includes a low-yield point steel plate 1 and an aluminum alloy plate 2, and two low-yield point plates with uniform shapes and specifications The steel plate 1 sandwiches an aluminum alloy plate 2 in the middle and overlaps to form a straight-shaped core energy-dissipating plate, and the core energy-dissipating plate is embedded in the abdominal cavity of the double-web I-steel restraint member 3 composed of two I-shaped steels to form a double yield Point-shaped all-steel buckling-resistant energy-dissipating supports, and the two ends of the core energy-dissipating plate are located outside the abdominal cavity of the double-web I-steel restraint member 3 for connection with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com