Multi-level synchronous telescopic oil cylinder flow compensation device

A technology of flow compensation and telescopic oil cylinder, which is applied in the field of hydraulic control valves, and can solve problems such as poor control of one-way valve opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

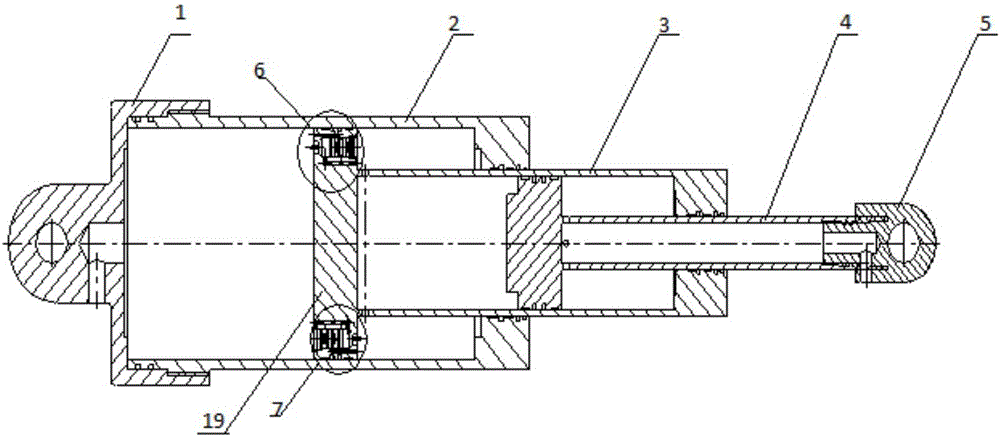

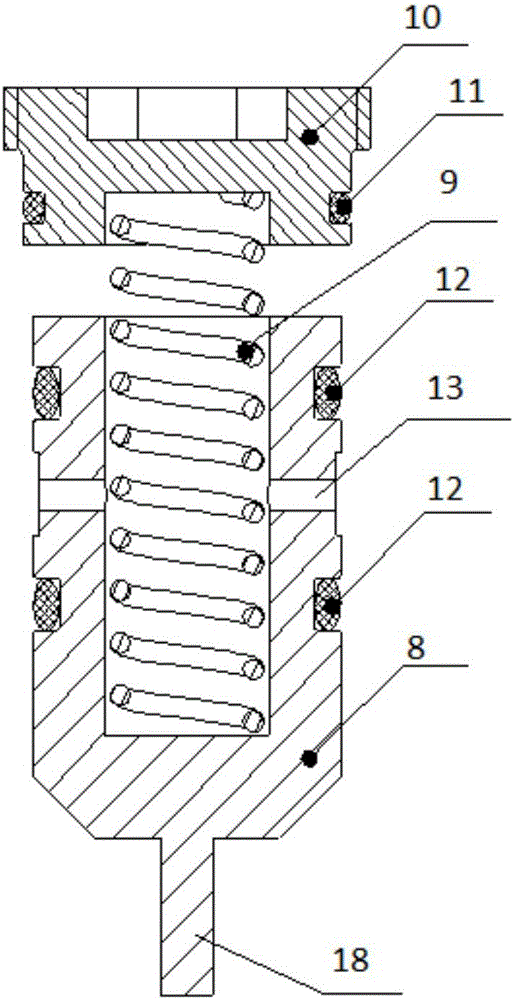

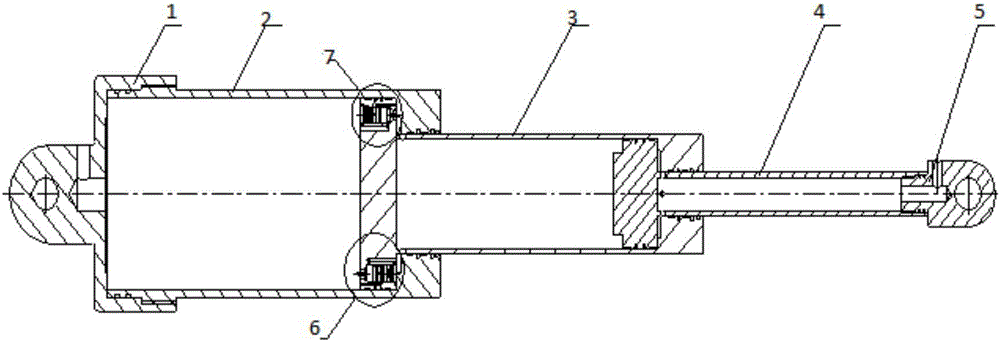

[0024] Preferred embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and are used together with the embodiments of the present invention to explain the principles of the present invention.

[0025] This embodiment provides a flow compensation device for a multi-stage synchronous telescopic oil cylinder. Two two-position two-way valves in pairs are installed inside the piston, which can move with the piston; the two-position two-way valve is a stroke-triggered Two-position two-way valve, one end of the two-position two-way valve has a stroke trigger switch. When the two-position two-way valve moves to the limit position with the piston, due to the contact between the stroke trigger switch and the external barrier (the end surface of the adjacent cylinder and the corresponding adjacent to the piston end face of the oil cylinder), an external ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com