Novel light truck hub unit

A technology for automobile hubs and light trucks, which is applied in the field of auto parts, can solve the problems of difficult structural assembly, high cost, and long service life, and achieve the effects of simple structure, improved life, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

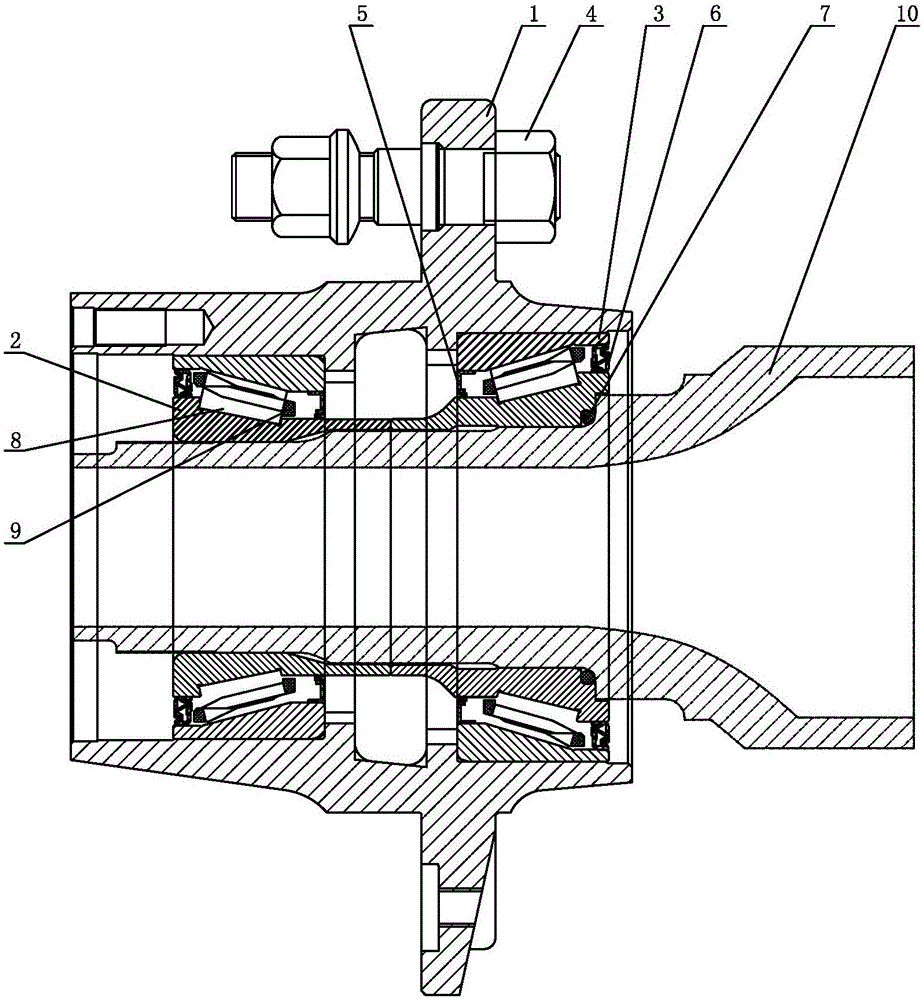

[0026] Such as figure 1 As shown, a new light truck hub unit mainly includes a hub 1, a first bearing 2 and a second bearing 3, the first bearing 2 and the second bearing 3 are respectively located at both ends of the hub 1, the first bearing 2 and the second bearing 3 all include a 9 retainer and a number of rolling elements 8, and a number of hub bolts 4 are also connected to the hub 1.

[0027] The inner right end of the hub 1 is sequentially provided with a combined seal 6, an O-ring 7, a single seal 5, a single seal 5, and a combined seal 6 from right to left, and the combined seal 6 and the single seal 5 are located between the first bearing 2 and the Between the inner and outer rings of the second bearing 3, the O-ring 7 is located between the large end surface of the inner ring of the second bearing 3 and the shaft.

[0028] The inner ring of the first bearing 2 and the inner ring of the second bearing 3 are in contact with each other, the hub 1 is a cylindrical struc...

Embodiment 2

[0031] A new light truck hub unit mainly includes a hub 1, a first bearing 2 and a second bearing 3, the first bearing 2 and the second bearing 3 are respectively located at both ends of the hub 1, the first bearing 2 and the second bearing 3 are both It includes a 9 retainer and a number of rolling elements 8, and a number of hub bolts 4 are also connected to the hub 1.

[0032] The inner right end of the hub 1 is sequentially provided with a combined seal 6, an O-ring 7, a single seal 5, a single seal 5, and a combined seal 6 from right to left, and the combined seal 6 and the single seal 5 are located between the first bearing 2 and the Between the inner and outer rings of the second bearing 3, the O-ring 7 is located between the large end surface of the inner ring of the second bearing 3 and the shaft.

[0033] The inner ring of the first bearing 2 and the inner ring of the second bearing 3 are in contact with each other, the hub 1 is a cylindrical structure, the shape of ...

Embodiment 3

[0036] A new light truck hub unit mainly includes a hub 1, a first bearing 2 and a second bearing 3, the first bearing 2 and the second bearing 3 are respectively located at both ends of the hub 1, the first bearing 2 and the second bearing 3 are both It includes a 9 retainer and a number of rolling elements 8, and a number of hub bolts 4 are also connected to the hub 1.

[0037] The inner right end of the hub 1 is sequentially provided with a combined seal 6, an O-ring 7, a single seal 5, a single seal 5, and a combined seal 6 from right to left, and the combined seal 6 and the single seal 5 are located between the first bearing 2 and the Between the inner and outer rings of the second bearing 3, the O-ring 7 is located between the large end surface of the inner ring of the second bearing 3 and the shaft.

[0038] The inner ring of the first bearing 2 and the inner ring of the second bearing 3 are in contact with each other, the hub 1 is a cylindrical structure, the shape of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com