Geological survey drilling rig

A technology of geological survey and drill, which is applied in drilling equipment, earthwork drilling, percussion drilling, etc. It can solve the problems of uncontrollable dust, affecting observation, and unfavorable safety of surrounding personnel and the environment, so as to save manpower and improve drilling efficiency. Effect of Pore Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

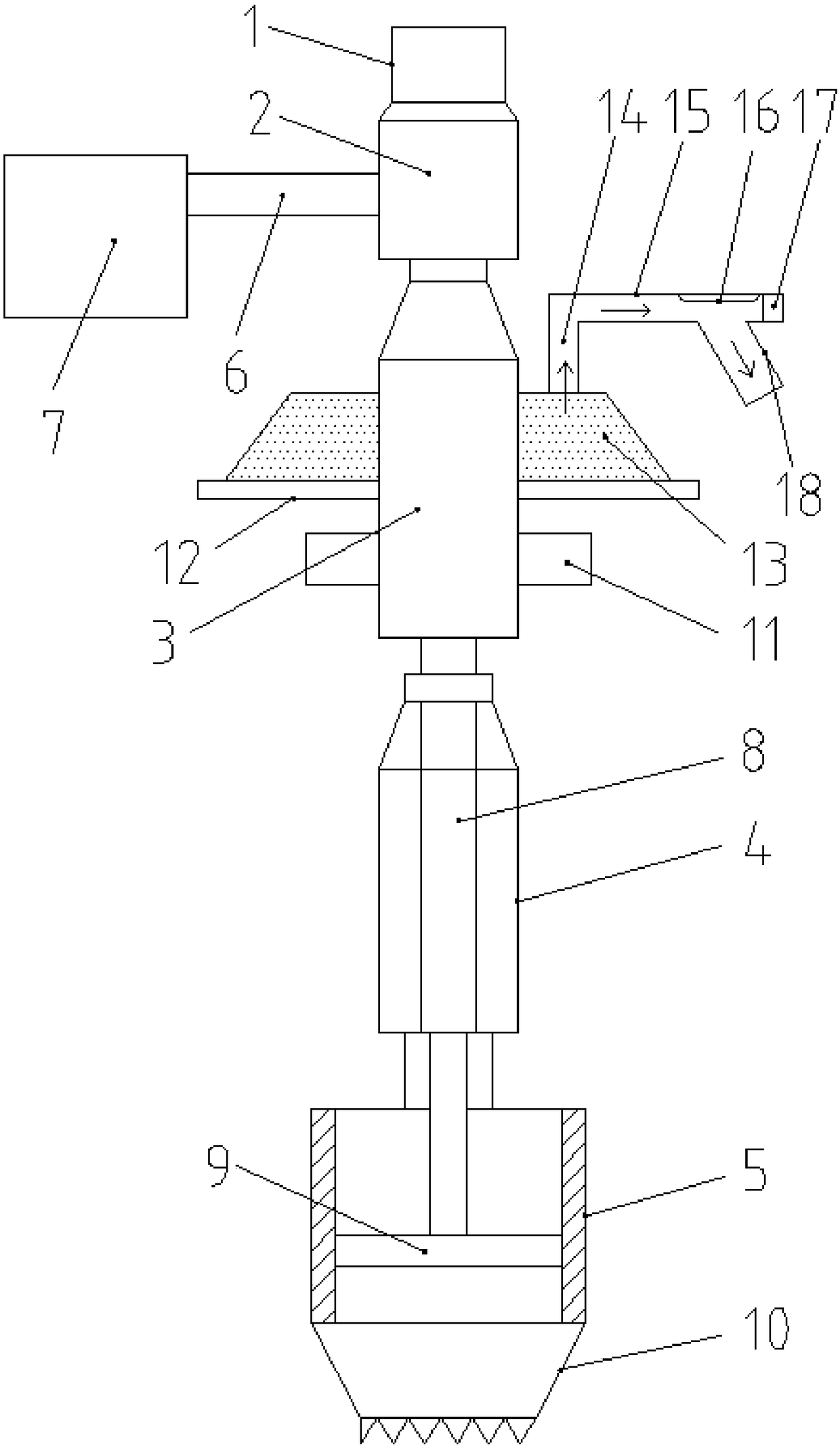

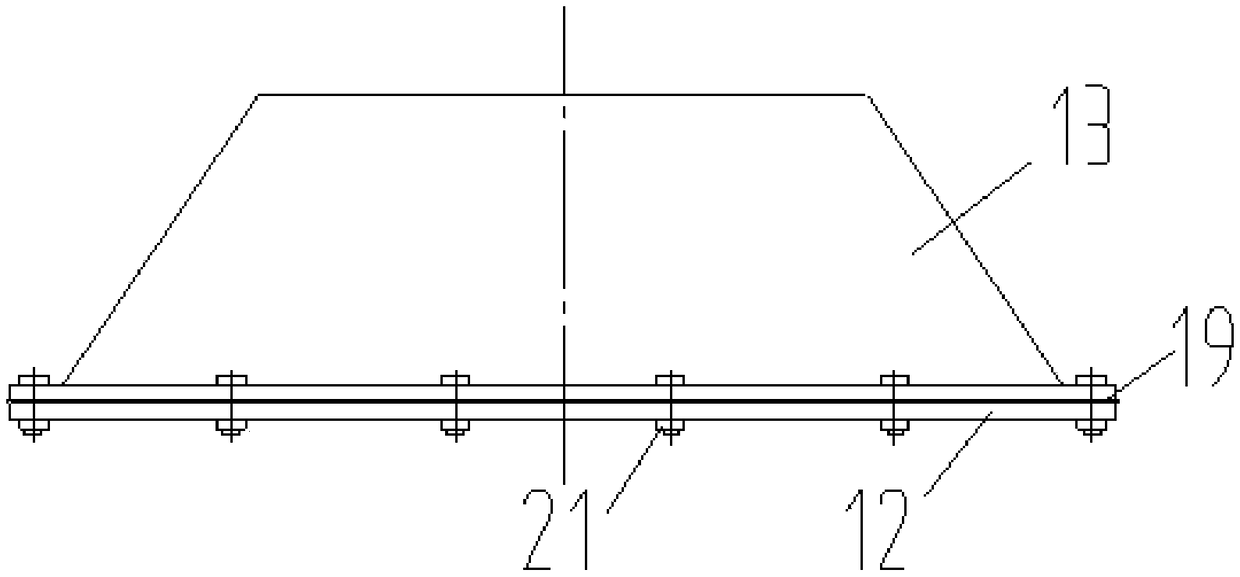

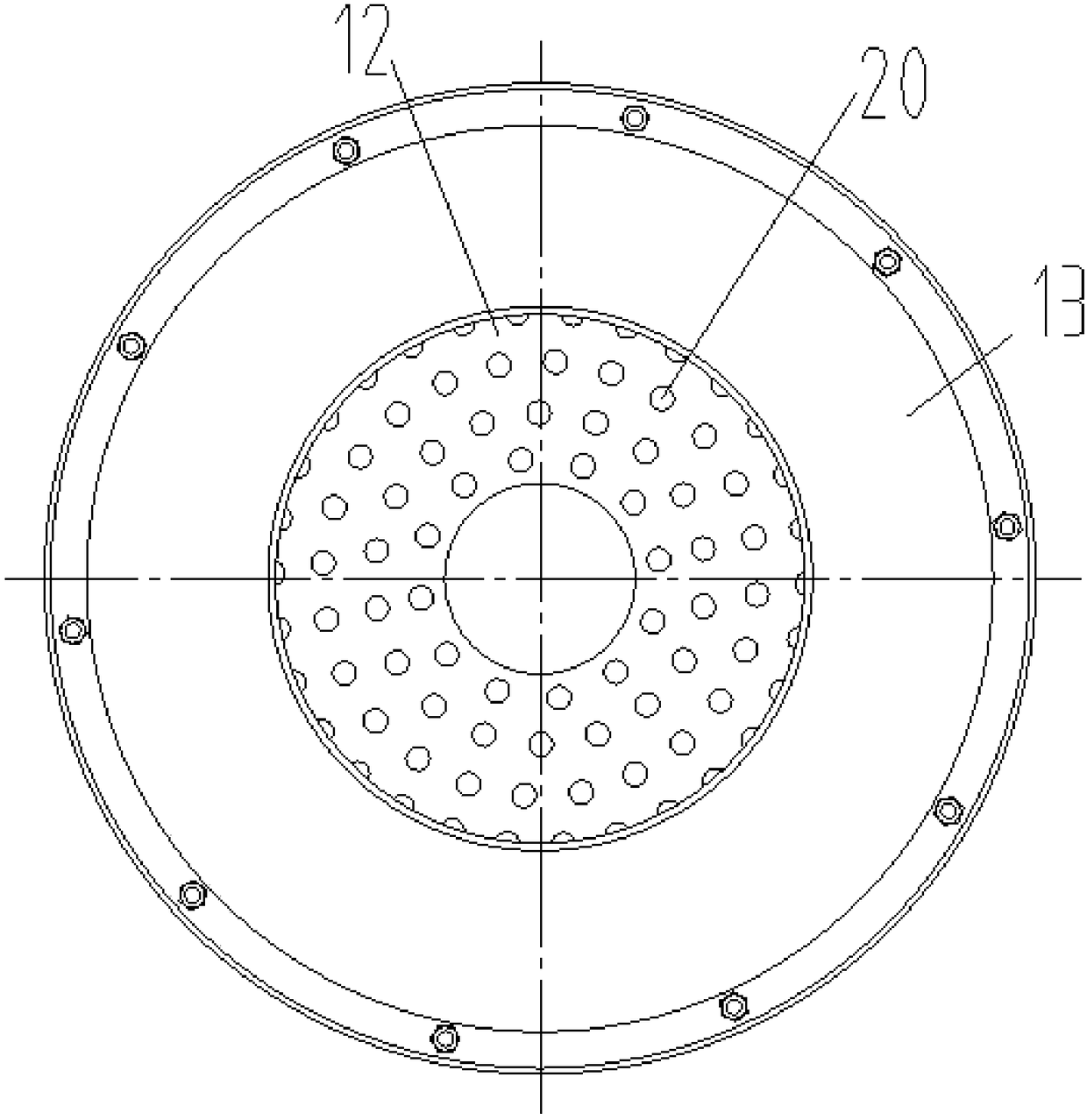

[0029] Further, see figure 1 , as a specific embodiment of the geological survey drill provided by the present invention, the recovery pipe includes a vertical pipe 14 and a horizontal pipe 15 arranged in an L shape, and the lower end of the vertical pipe 14 is connected to the top of the storage bin 13 In communication, the spray mechanism is arranged at the end of the horizontal pipe 15 . By arranging a spraying mechanism at the end of the horizontal pipe, the backflow of mud formed after the dust-laden air flow is sprayed by the spraying mechanism can be avoided.

[0030] Further, see figure 1 , as a specific embodiment of the geological survey drill provided by the present invention, the spray mechanism includes a water mist nozzle 16 and a water outlet pipe 18, and the water mist nozzle 16 is arranged on the top inner wall of the horizontal pipe 15, The water outlet pipe 18 is arranged at the bottom of the horizontal pipe 15 and communicated with the horizontal pipe 15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com